L-26 Switch Mode Power Supply S8TS

Specifications

■Ratings/Characteristics

24/12-V Models (Basic Block: S8TS-06024@/S8TS-03012@)

Note 1. Refer to page 31 for details on adjusting the output voltage for parallel operation. If set to less than −10%, the undervoltage detection func-

tion may operate. Ensure that the output capacity and output current after adjustment do not exceed the rated output capacity and rated

output current respectively.

2. Class 2 approval does not apply to parallel operation.

3. The output current is specified at power output terminals.

4. Refer to the explanations of functions on page 28 for details.

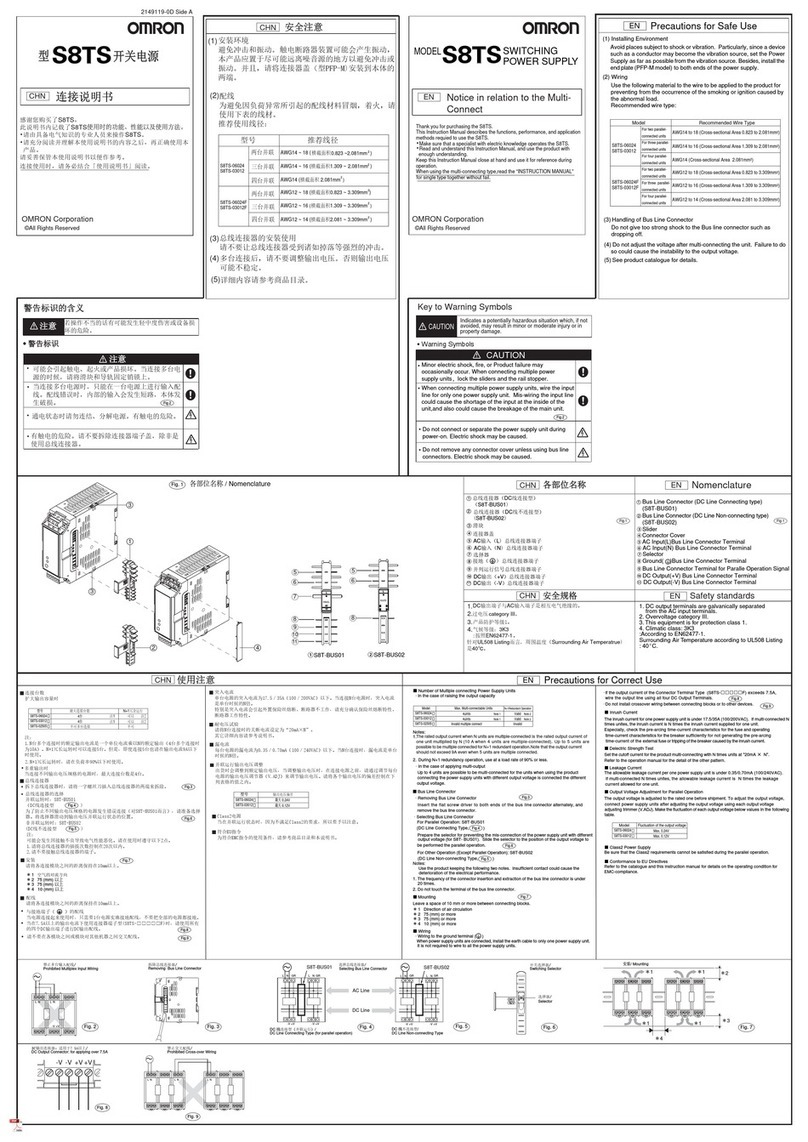

5. Be sure to mount End Plates (PFP-M) on both ends of the Power Supply.

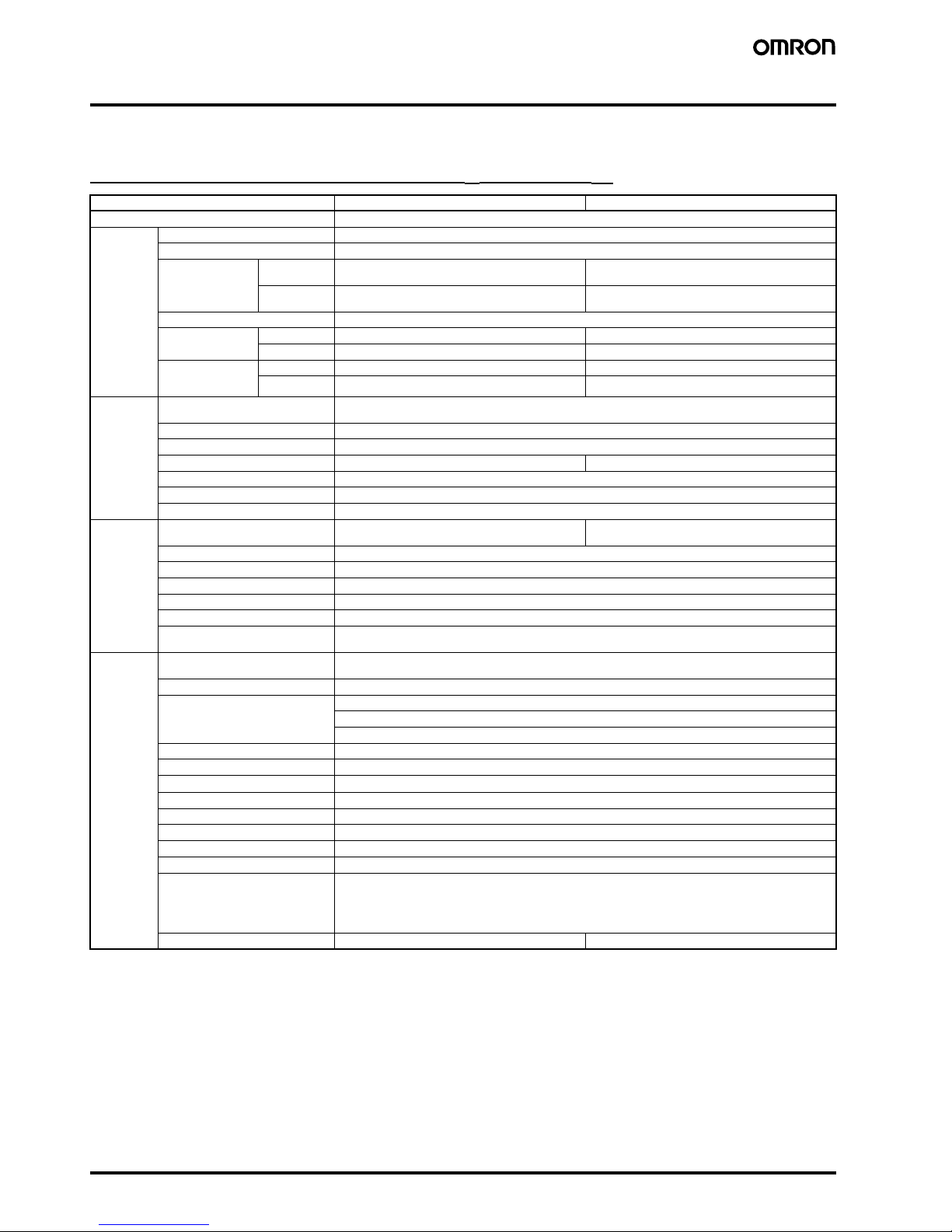

Item Single operation Parallel operation

Efficiency 24-V models: 75% min.; 12-V models: 70% min. (with rated input, 100% load)

Input Voltage 100 to 240 VAC (85 to 264 VAC)

Frequency 50/60 Hz (47 to 63 Hz)

Current 100 V input 24-V models: 1.0 A max.

12-V models: 0.7 A max. 24-V models: 1.0 A ×(No. of Blocks) max.

12-V models: 0.7 A ×(No. of Blocks) max.

200 V input 24-V models: 0.5 A max.

12-V models: 0.4 A max. 24-V models: 0.5 A ×(No. of Blocks) max.

12-V models: 0.4 A ×(No. of Blocks) max.

Power factor 24-V models: 0.9 min.; 12-V models: 0.8 min. (with rated input, 100% load) (See note 3.)

Leakage current 100 V input 0.35 mA max. 0.35 mA × (No. of Blocks) max.

240 V input 0.7 mA max. 0.7 mA × (No. of Blocks) max.

Inrush current

(25°C, cold start)

(See note 4.)

100 V input 25 A max. 25 A × (No. of Blocks) max.

200 V input 50 A max. 50 A × (No. of Blocks) max.

Output (See

note 3.) Voltage adjustment range 24-V models: 22 to 28 V

12-V models: 12 V ±10% (with V.ADJ) (See note 1.)

Ripple 2% (p-p) max.

Input variation influence 0.5% max. (with 85 to 264 VAC input, 100% load)

Load variation influence 2% max. (with rated input, 10% to 100% load) 3% max. (with rated input, 10% to 100% load)

Temperature variation influence 0.05%/°C max. (with rated input and output)

Startup time (See note 4.) 1,000 ms max.

Hold time (See note 4.) 20 ms min. (with 100/200 VAC, rated input)

Additional

functions Overcurrent protection (See note 4.) 105% to 125% of rated load current, inverted L drop

type, automatic reset 100% to 125% of rated load current inverted L drop

type, automatic reset

Overvoltage protection (See note 4.) Yes

Parallel operation Yes, 4 Blocks max.

N+1 redundant system Yes, 5 Blocks max.

Series operation Yes

Undervoltage indicator (See note 4.) Yes (color: red)

Undervoltage detection output (See

note 4.) Yes (open collector output), 30 VDC max., 50 mA max.

Other Ambient operating temperature (See

note 4.) Operating: Refer to the derating curve in Engineering Data.

Storage: −25 to 65°C (with no icing or condensation)

Ambient humidity Operating: 25% to 85%; Storage: 25% to 90%

Dielectric strength 3.0 kVAC, 50/60 Hz for 1 minute (between all inputs and all outputs; detection current: 20 mA)

2.0 kVAC, 50/60 Hz for 1 minute (between all inputs and GR terminal; detection current: 20 mA)

1.0 kVAC for 1 minute (between all outputs and GR terminal; detection current: 20 mA)

Insulation resistance 100 MΩmin. (between all outputs and all inputs, and between all outputs and GR terminal) at 500 VDC

Vibration resistance 10 to 55 Hz, 0.375-mm single amplitude for 2 h each in X, Y, and Z directions

Shock resistance 150 m/s2, 3 times each in ±X, ±Y, and ±Z directions

Output indicator Yes (color: green)

Electromagnetic interference Conforms to FCC Class A, EN50081-1

EMI Conforms to EN50081-1/1992

Power factor correction Conforms to EN61000-3-2, EN61000-3-2 A14

EMS Conforms to EN61000-6-2/1999

Approved standards UL: 508 (Listing; Class 2: Per UL1310), 1950, 1604 (Class I, Division 2, Groups A, B, C, D

Hazardous Locations))

cUL: CSA C22.2 No.14, No.213 (Class I, Division 2, Groups A, B, C, D

Hazardous Locations), No. 950 (Class 2) (See note 2.)

EN/VDE: EN50178 (=VDE0160), 60950 (=VDE0806)

Weight 450 g max. 450 g ×(No. of Blocks) max.