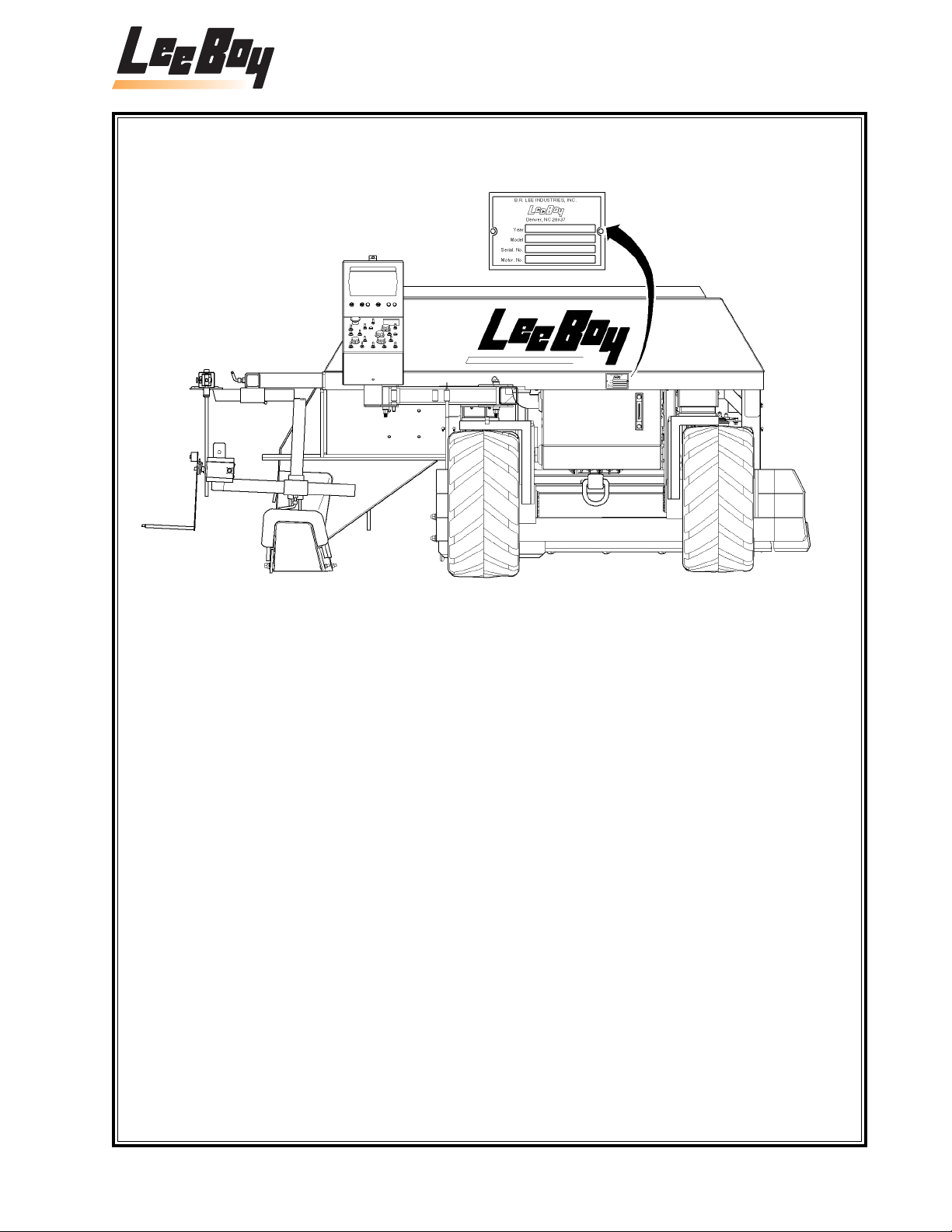

500 Lincoln County Parkway Ext.

Lincolnton, NC 28092

Tel: 704-966-3300

Fax: 704-483-5802

www.LeeBoy.Com

LIMITED WARRANTY

POLICY AND PROCEDURES

WARRANTY

1. If a defect in material or workmanship is found

and the authorized dealer is notified during the

warranty period, LeeBoy will repair or replace

any part of component of the unit or part that

fails to conform to the warranty during the war-

ranty period.

2. The warranty date will begin upon the comple-

tion of the warranty form by the initial cus-

tomer and will expire after twelve (12) months

have passed. The Warranty Card should be

filled out within ten (10) days of delivery of the

unit.

3. Engines are warranted by their manufacturers

and may have warranty coverage that differs

from that of LeeBoy.

4. Replacement parts furnished by LeeBoy are

covered for the remainder of the warranty peri-

od applicable to the unit or component in

which such parts are installed.

5. LeeBoy has the right to repair any component

or part before replacing it with a new part.

6. All new replacement parts purchased by a

LeeBoy dealer will carry a six (6) month war-

ranty. Remanufactured parts purchased by a

LeeBoy dealer will carry a ninety (90) day war-

ranty.

ITEMS NOT COVERED

LeeBoy is not responsible for the following:

1. Charges for travel time, mileage, or overtime.

2. Charges related to transporting the product to

and from the place at which warranty work is

performed.

3. Airfreight charges related to transporting repair

parts to the place at which warranty work is

performed.

4. All used units or used parts of any kind.

5. Repairs due to normal wear and tear, or

brought about by abuse or lack of mainte-

nance of the equipment, except for premature

failures, conveyor chains, polytrack pads, and

track rails.

6. Attachments not manufactured or installed by

LeeBoy.

7. Liability for incidental or consequential dam-

ages of any type including, but not limited to

lost profits or expenses of acquiring replace-

ment equipment.

8. Miscellaneous charges.

LIMITATIONS

LeeBoy has no obligation under this warranty for:

1. Any defects caused by misuse, misapplication,

negligence, accident or failure to maintain or

use in accordance with the most current oper-

ating instructions.

2. Unauthorized alterations.

3. Defects or failures caused by any replacement

parts or attachments not manufactured by or

approved by LeeBoy.

4. Failure to conduct normal maintenance and

operating service, including without limitation,

providing lubricants, coolant, fuel, tune-ups,

inspections or adjustments.

5. Unreasonable delay, as established by

LeeBoy, in making the applicable units or parts

available upon notification of a service notice

ordered by LeeBoy.

6. The warranty responsibility on all engines

and/or truck chassis rests with the respective

manufacturer.

7. LeeBoy may have support agreements with

some engine and/or truck chassis manufactur-

ers for warranty and parts support.

OTHER WARRANTIES

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU

OF ALL OTHER EXPRESSED STATUTORY AND IMPLIED

WARRANTIES APPLICABLE TO UNITS, ENGINES, OR

PARTS WITH LIMITATION, ALL IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR

USE OR PURPOSE. IN NO EVENT, WHETHER AS A

RESULT OF BREACH OF CONTRACT OR WARRANTY, OR

ALLEGED NEGLIGENCE OR LIABILITY WITHOUT FAULT,

SHALL LEEBOY BE LIABLE FOR SPECIAL, INCIDENTAL OR

CONSEQUENTIAL DAMAGES, INCLUDING WITHOUT LIMI-

TATION, LOSS OF PROFIT OR REVENUE, COST OF CAPI-

TAL, COST OF SUBSTITUTED EQUIPMENT, FACILITIES OR

SERVICES, DOWNTIME COSTS, LABOR COSTS OR

CLAIMS OF CUSTOMERS, PURCHASERS OR LESSEES

FOR SUCH DAMAGES.

LBC-24W Curber