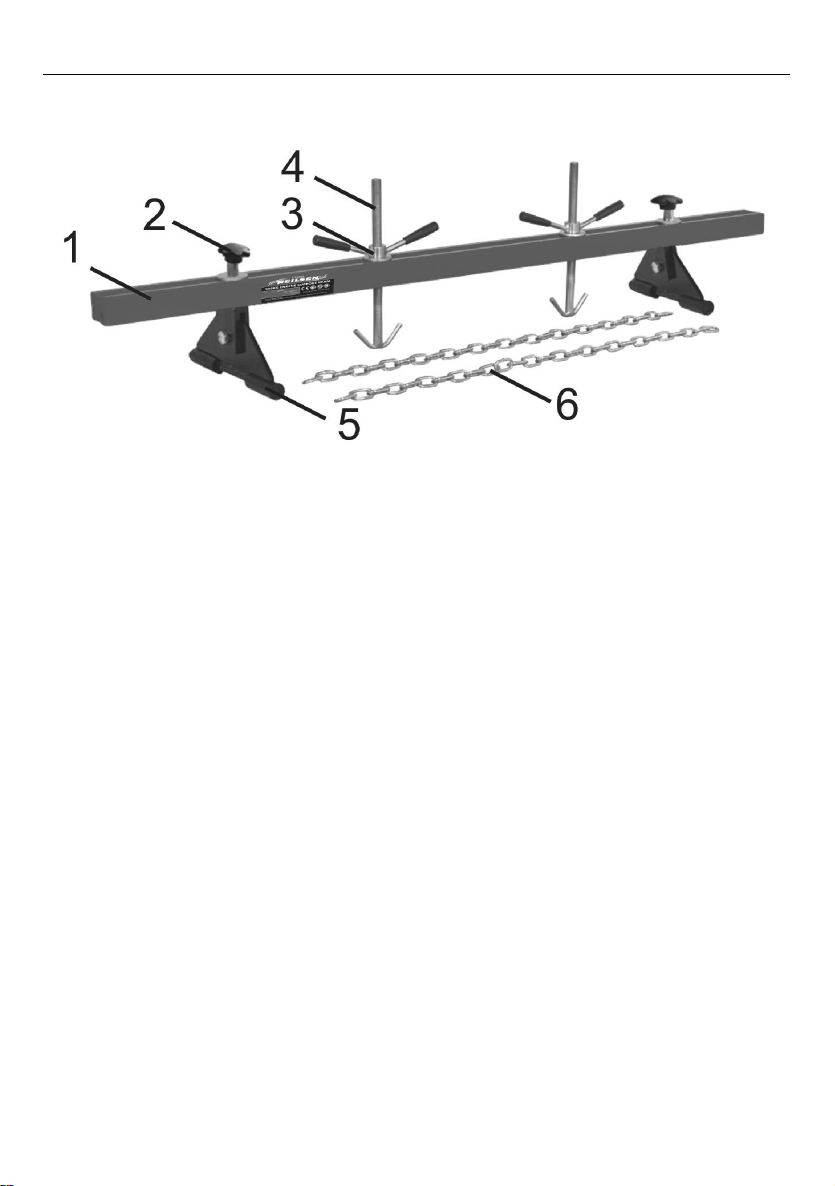

Model: CT4282

Capacity: 500KG

Working range: 730 - 1480mm

Adjustable height: 0 - 205mm

2. IMPORTANT SAFETY INFORMATION

1. Ensure that the engine support is in good working order. Take action for

immediate repair or replacement of damaged parts. Use genuine parts only.

The use of unauthorised parts may be dangerous and will invalidate the

warranty.

2. Locate the vehicle in a suitable, well lit work area.

3. Keep work area clean and tidy and free from unrelated materials.

4. Ensure the vehicle handbrake is engaged and the engine/motor is switched

off.

5. Ensure all non-essential persons keep a safe distance whilst the engine

support is in use.

6. DO NOT use the engine support if damaged.

7. DO NOT allow untrained persons to operate the engine support.

8. DO NOT use the engine support for purposes other than that for which it is

designed.

9. Never try to move a running or hot engine. Allow sufficient time for the engine

to cool down entirely before beginning any operations.

10. Do not overload. Overloading could cause damage and/or failure of the

engine support and vehicle.

11. Ensure the rubber supports are securely located in the gutter of the vehicle’s

front wing panels. NOT ON TOP OF THE WINGS.

12. Once the support is positioned correctly, tighten all locking knobs, nuts and

bolts etc.,before applying a load.

13. Always check that the engine/gearbox is properly secured to the support via

a suitable chain or sling.

14. When not in use, store engine support in a safe, dry, childproof area.