4

M1

PL1/N1

A/-

A2/-

PL2/N2

3455

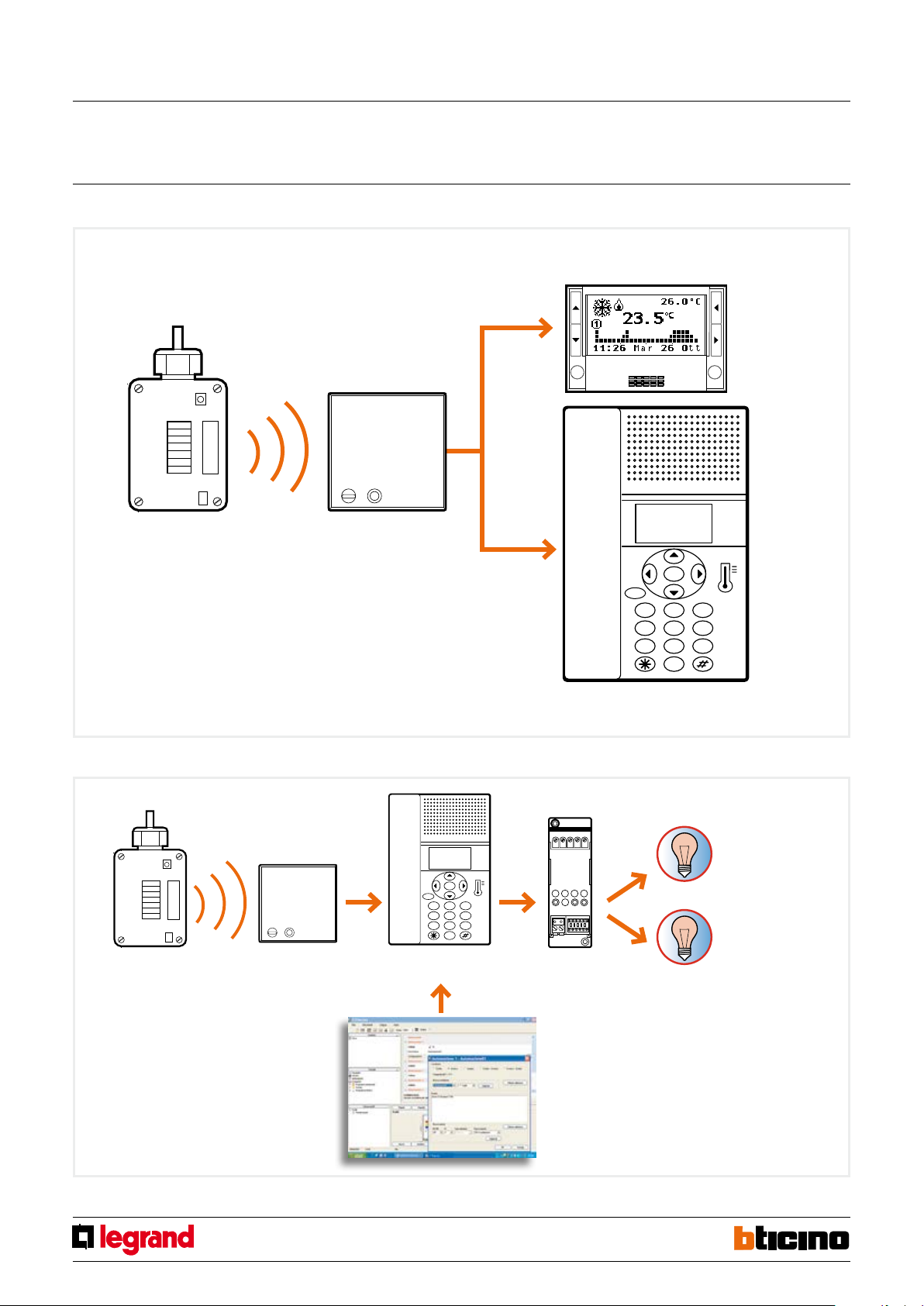

HC/HS 4577 and L/N/NT4577 receiving interface conguration

In order to use a receiving interface and radio probe, conguration must rst be

performed, followed by the programming procedure. Only the interface needs

conguring. Up to 2 probes may be combined with each interface, therefore providing

the system with two detection points for each interface. Up to a maximum of 9

temperature probes may be installed in one system.

The conguration sockets on the interface identify the radio probes addresses.They are:

A1/-, PL1/N1, M1 for the rst address, and A2/-, PL2/N2, M2 for the second address. The

two addresses must always be dierent from each other, PL1/N1 ≠ PL2/N2. Only one

radio probe may be associated to each address. Only used addresses must be congured.

The interface must be congured in temperature control mode by connecting

congurator 1 to M1 and M2. With this mode the A1/- and A2/- sockets are not

used, therefore no congurator needs to be connected.

Programming of devices:

After performing the conguration, it will be necessary to associate the radio probe to

the interface following the programming procedure:

1) Press the pin pushbutton of the interface for 5 seconds. The red LED turns on.

Release the pushbutton. The interface LED will ash every two seconds to conrm

that programming mode is active on the rst address (group of congurators PL1/

N1, M1). If the second address of the interface is not congured (no congurator is

connected to the PL2/N2, M2 positions), go to step 2 of the procedure.

However, if also the second address must be congured (group of congurators PL2/

N2, M2), simply press the pin pushbutton of the interface again.

The LED will ash twice in succession every two seconds.

Every time the pin pushbutton is pressed, the system will switch from the rst to the

second address and vice versa.

2) After choosing the address, The radio probe should be associated to, within 20

seconds press the transmission key of the probe itself. Pressing the transmission key

will send the probe serial code. After receiving the code through the radio signal, the

red LED of the interface will quickly ash for 2 seconds, conrming that programming

is complete, and the procedure has been terminated.

If necessary repeat the operation to save the code of another probe. If on the other hand

an address has already been associated and the procedure is repeated with another

probe, the interface performs an overwriting action, only keeping the last probe in

memory. During normal operation, the sending of information from the probe is

conrmed by the ashing of the red LED of the interface. A single ashing indicates that

the radio message has been received, and the“temperature”data has been sent through

the BUS by a probe associated to the PL1/N1, M1 address. A double ashing indicates

that the radio message has been received, and the “temperature” data has been sent

through the BUS by a probe associated to the PL2/N2, M2 address. To delete all codes

from the interface press the pin pushbutton for 12 seconds. After 5 seconds from pressing

the key, the LED will turn on steadily, and after a further 7 seconds, it will start ashing

quickly, conrming that all programs have been deleted.

NOTES:

- If the interface conguration is wrong, the red LED will ash. Correct the conguration.

- If the second interface address has not been congured (no congurator connected to

the PL2/N2, M2 sockets), during the programming procedure it will not be possible to

switch to this address, which therefore cannot be programmed.

Interface back view

Congurator

socket

MQ00182-c-EN 29/04/2014

Radio outdoor

temperature probe