Koehler Instrument Company, Inc.

1595 Sycamore Avenue • Bohemia, New York 11716-1796 • USA

Toll Free: 1-800-878-9070 (US only) • Tel: +1 631 589 3800 • Fax: +1 631 589 3815

Petroleum Testing & Analysis Instrumentation • Custom Design & Manufacturing

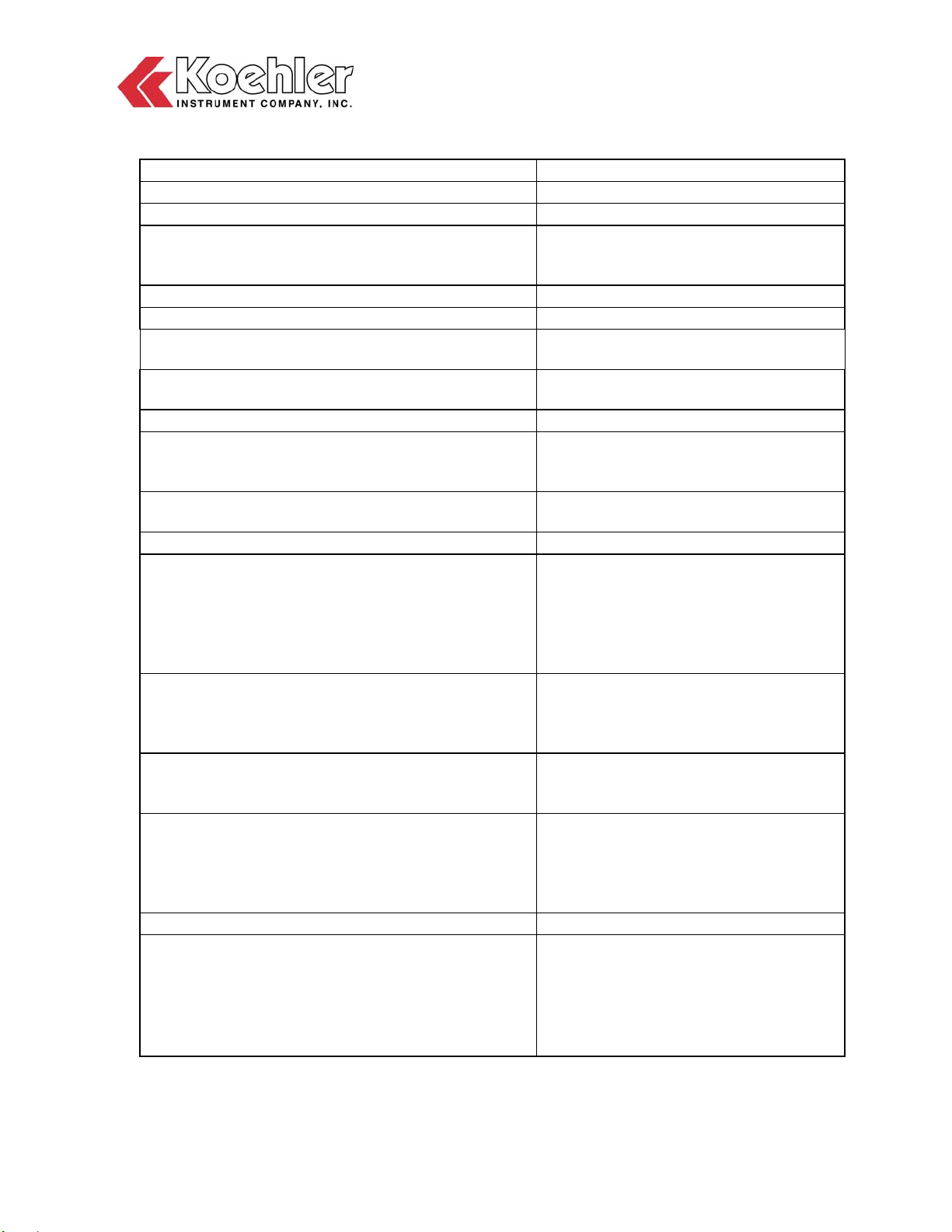

Ambient working temperature 15°C to 30°C

Working temperature range -20 °C to 400 °C

Detection temperature range -70 °C to 700 °C

Sample temperature measurement 4-wired glass Pt100 probe,

accuracy

0,1°C

Flash point detection Ionization and or thermocouple

Flame dipping Automatic with gas or electrical

Test electric spark Electrical supply potentiometric tune

up

Stirring 2 speeds : 90 to 120 rpm,

240 to 260 rpm

Cooling of heating block Air ventilation and/or refrigerant

Gas supply Gas network (50 mbar max),

optional gas cartridge (about 8H of

autonomy)

Water supply Water network (5 psi max)

Connection : ext. diameter 12,5 mm

Pilot and test flame Adjustable by valves

Safety of heating Hard heating cut-off at 550°C

Measured in the heating block,

Independently of the

microprocessor,

With sound alarm

Safety on samples Cut-off of on-going test with sound

alarm ; programmable safety from

15°C to 99°C above expected

temperature

Probe safety Faulty probe ; abnormal

temperature

reading

Gas safety Optical detection of flame absence

with sound alarm and automatic

gas

cut-off after 30" and test

termination

Apparatus management Carte 386SX

Programming through tactile keyboard with

membrane Automatic barometric correction :

with manual registration of the

atmospheric pressure or by

pressure transducer

Selection of the units : °C, °F,

mbar, mm Hg