CONTENTS and STANDARDS

vi

SUPERJIG-12-18-24 User Guide

VRS Models

Item VRS12 Vacuum & Router Support for the Super 12 Dovetail Jig

Item VRS18 Vacuum & Router Support for the Super18 Dovetail Jig

Item VRS24 Vacuum & Router Support for the Super 24 Dovetail Jig

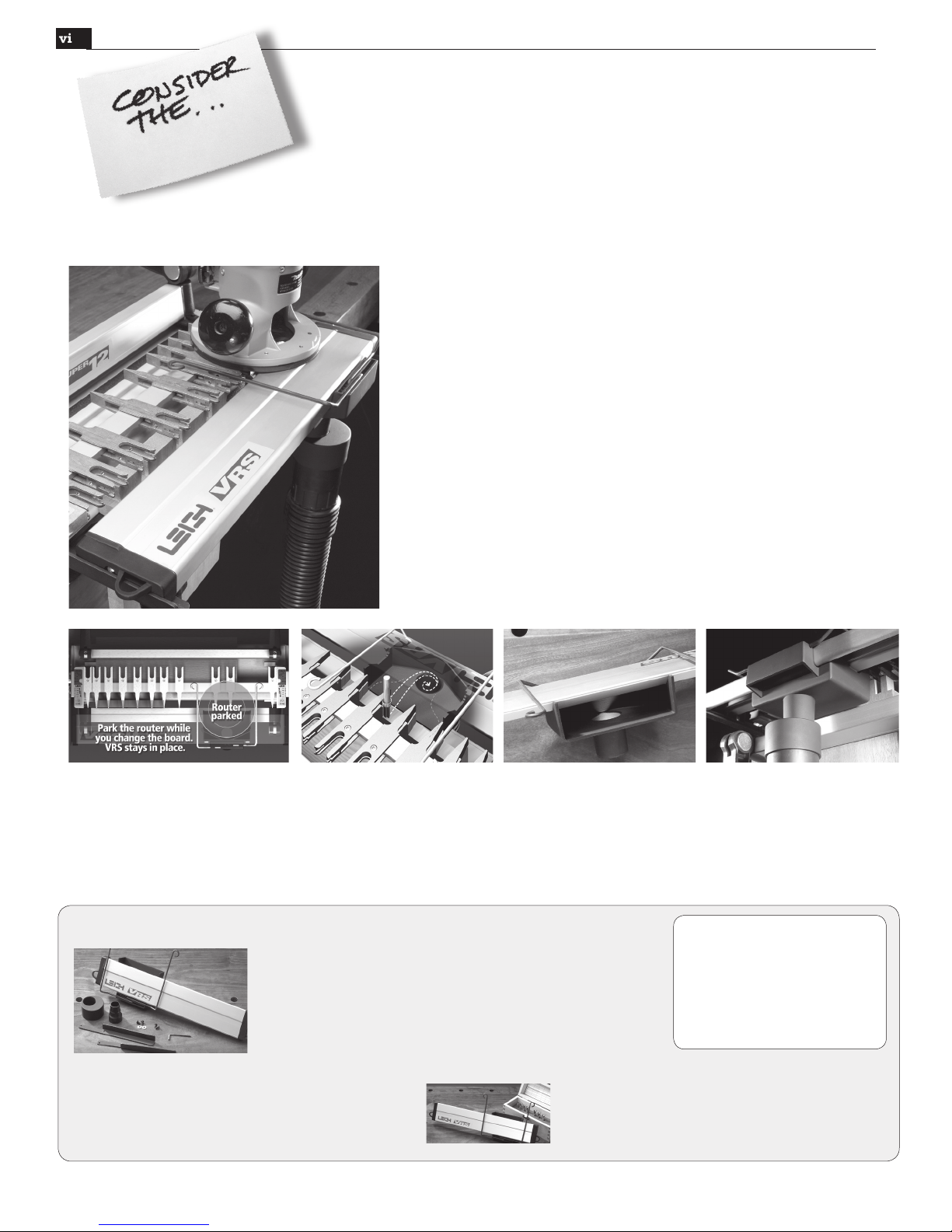

Dust-Free Routing!

The revolutionary Leigh VRS Vacuum & Router Support* provides almost 100%

dust and chip collection as well as amazing full width router support. The VRS

is a must-have for all Leigh dovetail jig owners.

*US patent: USPN 7,507,060 B2 UK patent: GB2446909

Here’s How It Works

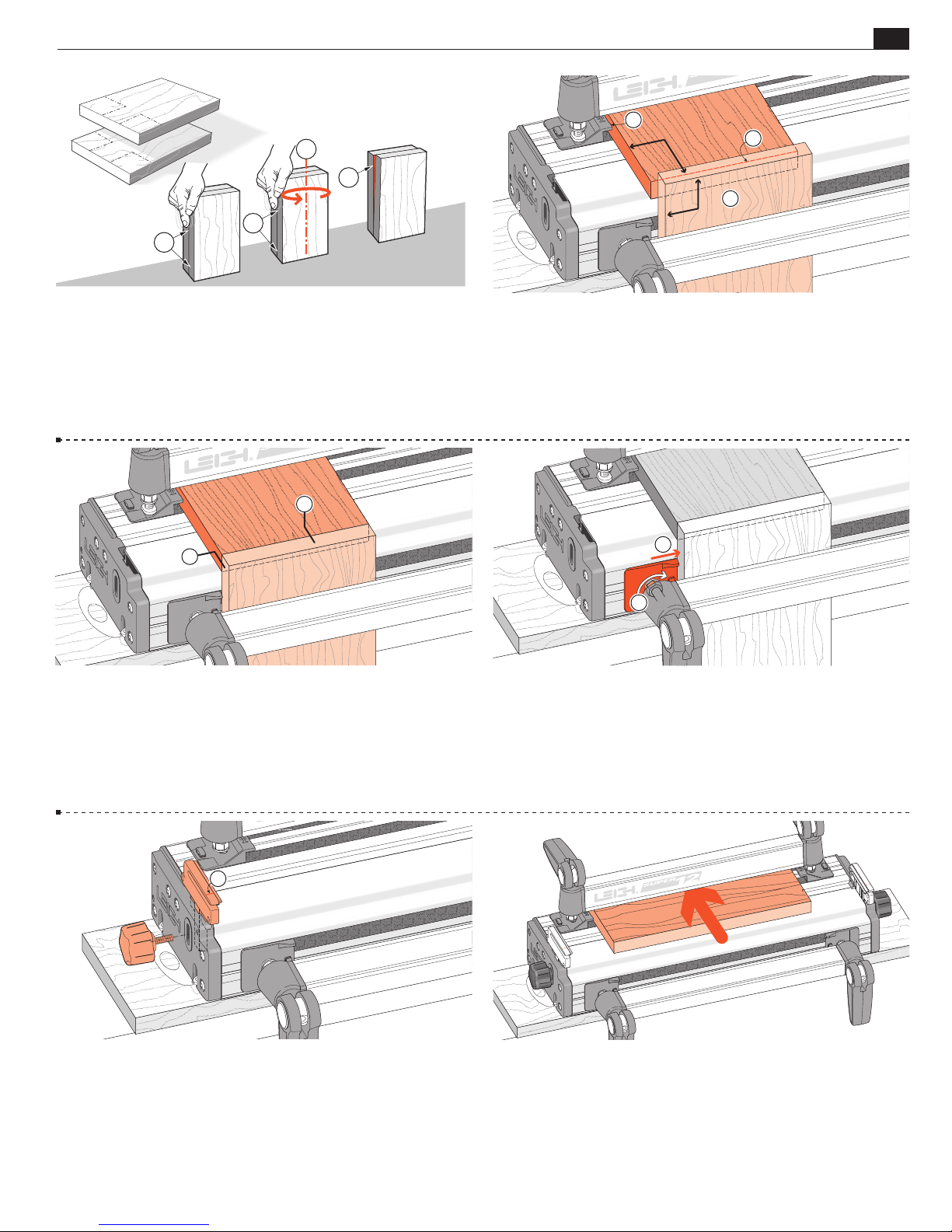

The VRS is mounted on brackets on the front of the jig and the router is sup-

ported by the finger assembly and the full width beam of the VRS. The vacuum

chute rides under the router support beam. Control arms, attached to the

vacuum chute, surround the router. These arms are adjustable to accommodate

any router base. As the router moves across the joint, the vacuum chute glides

effortlessly from side to side on nylon rollers. The chute is always in perfect

position to catch the dust and chips thrown out by the router bit. Chips and

sawdust are drawn into the vacuum chute and down through the vacuum hose.

Each VRS comes complete with two adaptors to fit all popular vacuum hose

sizes and the VRS can be used with a small shop vac or a large built in system.

The VRS is easily attached without jig modification. Each VRS comes complete

with all mounting hardware needed for any Leigh 24" D-Series jig, all Super

Jigs or the earlier model Leigh D1600.

VRS Vacuum & Router Support Features

• Full width router support

• Easy on Easy Off. Powerful rare earth

magnets secure router support beam

• Park the router when not in use

• Vacuum box glides effortlessly under

router support beam

• Control arms position vacuum box

• Control arms adjust to any router

• No hoses to obstruct view

• No jig modifications necessary

• Models for all Leigh jigs

• All mounting hardware included

• Adapt to any hose size

The dust chute rides beneath the

router support beam. Control arms

ensure accurate positioning of the

chute and the size and shape of the

chute ensures total waste collection

regardless of bit size or joint type

being routed.

The VRS will work with almost any

shop vac or large vac system. Two

adaptors are included with every

VRS to handle hose sizes from 1"

to 2-1/2".

The VRS is a full width router support.

When the work piece has been routed

on one side of the jig, the router can be

effortlessly moved to the other side of

the jig and parked while the work piece

is being changed. There is no need to

remove the router from the jig.

Because the vacuum box is always

in perfect position relative to the

router bit, the dust and chips com-

ing off of the router bit are auto-

matically drawn into the chute and

vacuum hose.

Accessory Kits

Item AC12 VRS12 and 1607-8 Bit Set for the Super 12 Dovetail Jig

Item AC18 VRS18 and 1607-8 Bit Set for the Super 18 Dovetail Jig

Item AC24 VRS24 and 1607-8 Bit Set for the Super 24 Dovetail Jig

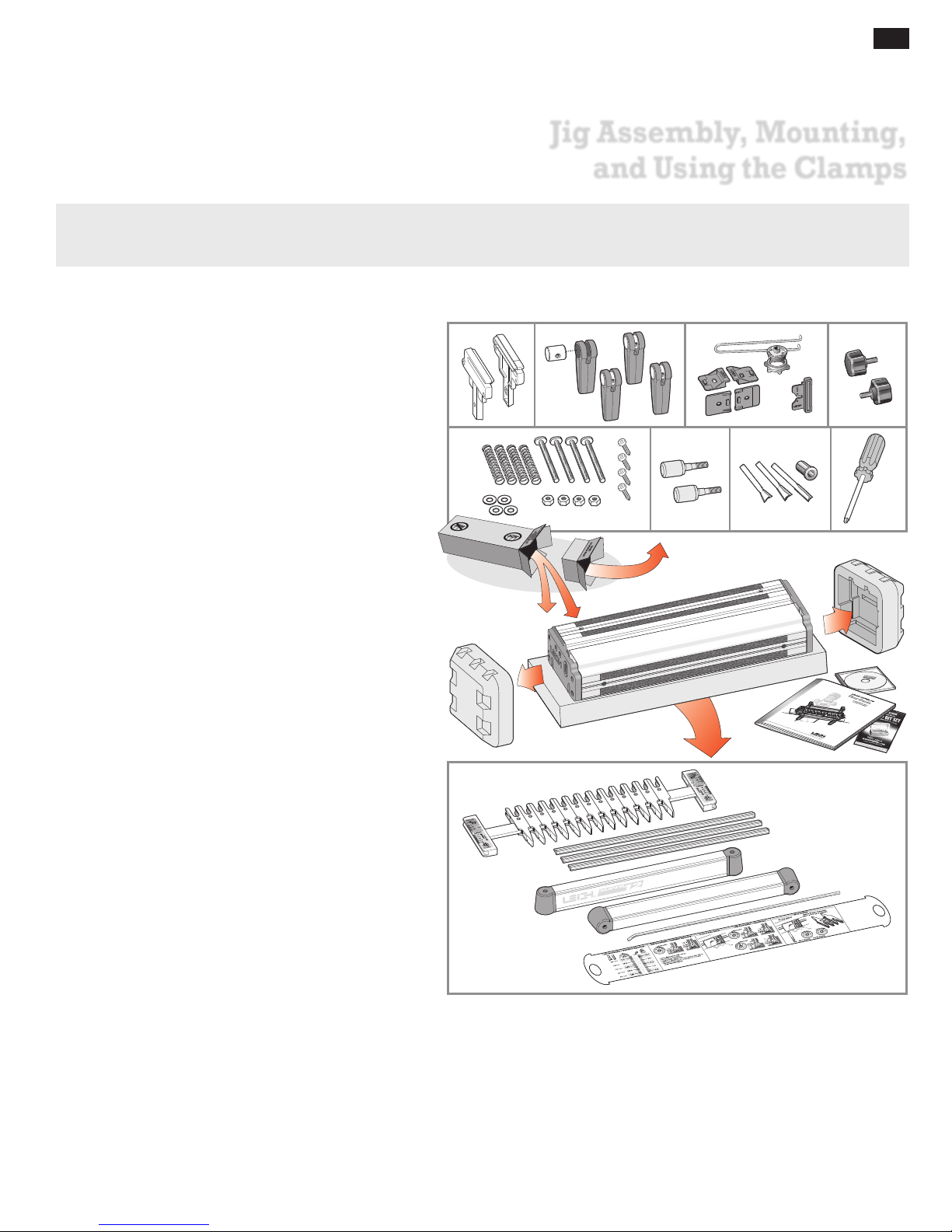

Standard Equipment

• Router Support Beam

• Vacuum chute

• Hose adaptors – small and large

• Support rails

• Screws and washers

• Hex key

Leigh VRS

Vacuum & Router Support