Page 5 of 11

SOIL PREPARATION PRIOR TO DIGGING

DIGGING OR EXCAVITING RECOMMENDATIONS FOR THE INSTALLATION

OF THE LIFTING AND STORAGE BASE

IMPORTANT:

To avoid breakage or malfunction, handle the lifting system with care as it contains the assembled batteries

and control box.

Prior to digging or excavating the ground for the PIVO | LEKLA Multi-Purpose Autonomous Energy Station, make sure

that its installation does not compromise or alter in any way the integrity of existing power lines or underground

equipment on site and that the work can be carried out in complete safety, without risk of electrocution, explosion,

leakage or collapse.

It is therefore your duty to inform yourself of the presence of underground pipes (sewer, water, gas, etc.), electricity,

telephone lines, tv cable by contacting the agencies concerned. If the work is carried out near a surface drain or

manhole, make sure to inform yourself with competent services that the installation of the PIVO | LEKLA will in no

way alter them.

Finally, if the work is carried out near overhead and/or underground power lines, make sure, before starting the work,

to secure the perimeter if necessary and provide a safe distance for your equipment to avoid any risk of electrocution.

NOTE :

Location of the base of the Autonomous Energy Station and identification of the type of soil are the responsi-

bility of the client and in no case the responsibility of LEKLA.

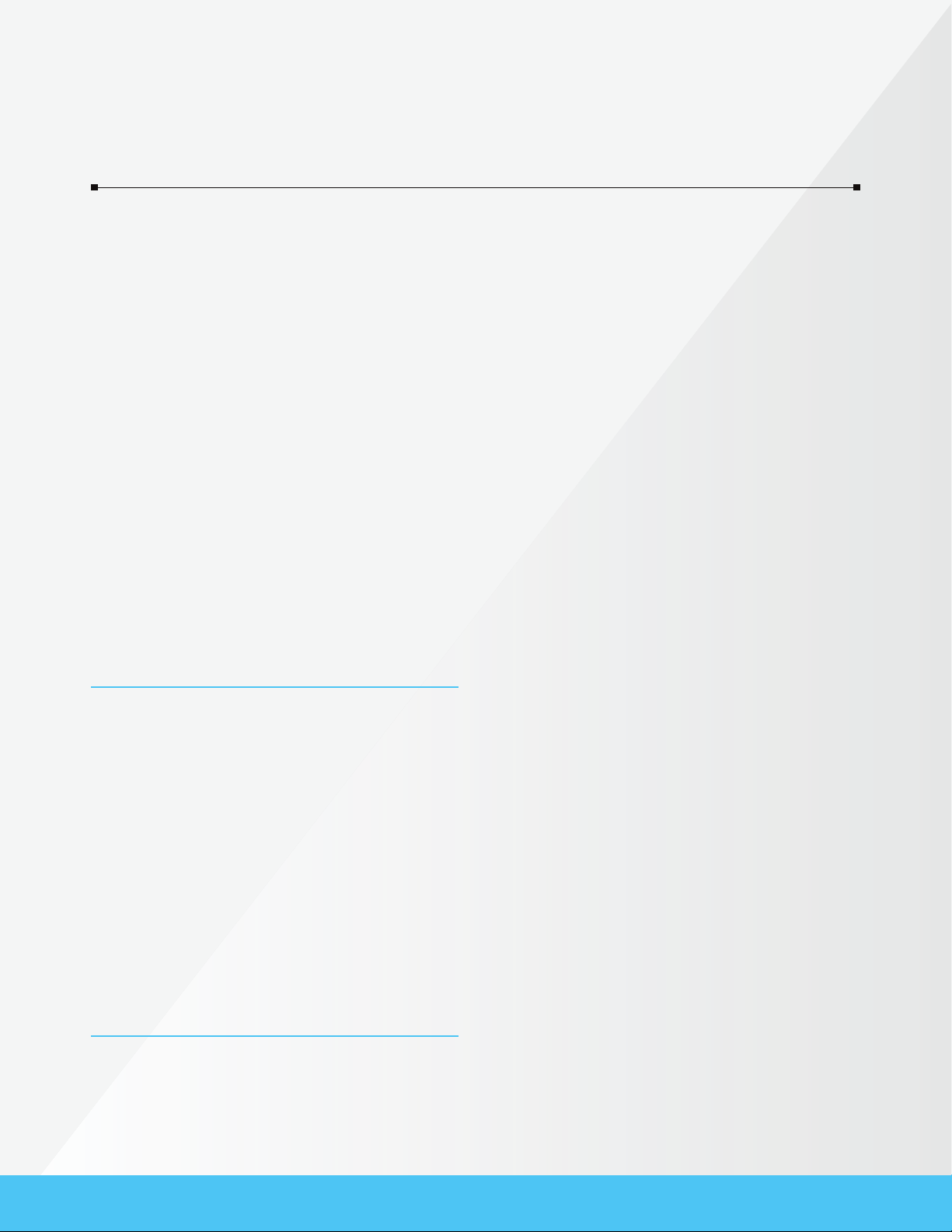

The recommended diameter of the hole is 610 mm (24 in.), which is the smallest diameter required for optimal

installation conditions. It is important to respect the 1657 mm (65 in.) depth of support at the base of the pole.

The arrow on the cylinder represents the position of the

service door when the base is open. It also servesas a

reference to correctly position the bolts when installing

the pole, so that the accessories (camera, light, etc.)

are correctly oriented (Figure 3).

NOTE:

It is suggested to locally compact the soil around

the periphery of the cylindrical tube as fill material,

such as rock dust, is added.

Figure 3

____________

Figure 3: Typical installation of PIVO | LEKLA Multi-Purpose Autonomous Energy Station base.e