2

WARNING

1) Do not spray paints or other inflammable fluids

indoors which have a flash point below 21 degree C, 70

degree F. Keep spray area well ventilated. Before

spraying, turn off all pilot lights and open flames.

2) Wear a respirator which is approved for the product

being sprayed.

3) Do not use halogenated hydrocarbon solvents in this

system; it contains aluminium parts and may explode.

Cleaning agents, coatings, paints, and adhesives may

contain halogenated hydrocarbon solvents. Don't take

chances, consult your material supplier to be sure. (ex:

methylene chloride and 1,1,1 - Trichlorethane)

4) Caution: When a flammable liquid is sprayed there may

be danger of fire or explosion especially in a closed

area.

5) Caution: Arcing parts. Keep the turbine at least 20 feet

away from explosive vapours.

6) Caution: Static electricity can be developed by

spraying. Ground unit and object to be sprayed. On

electric units, unit power cord must be connected to a

grounded outlet. Use only three wire extension cords.

Static explosion can occur with ungrounded unit.

7) Always follow safety precautions and warnings printed

on paint container.

ATTENTION

1) Ne jamais pulvériser à l’interieur un produit inflammable qui a un point

éclair inférieur à 21 degrés C,70 degrés F. L’endroit où vous peinturez doit

toujours être bien aéré. Avant de pulvériser s’assurer qu’il n’y a aucune

flamme ou pilot (veilleuse) de fournaise en marche dans l’appartement.

2) Servez-vous d’un masque respiratoire qui est certifié pour le produit que

vous pulvérisez.

3) Ne pas utiliser de solvants contenant des hydrocarbures halogénés

avec ce matériel. Il contient des particules d'aluminium et peut exploser. Les

agents de nettoyage, enduits, peintures et, adhésifs, peuvent contenir des

solvants contenant des hydrocarbures halogénés. Soyez prudents;

consultez votre fournisseur pour les informations nécessaires. (ex:

méthylène chloride and 1,1,1 - Trichloréthane)

4) Attention: La pulvérisaton d'un liquide inflammable peut entraîner un

risque d'incendie ou d'explosion, surtout dans les espaces fermés.

5) Attention: Étincelles électriques. Ne pas placer la turbine à moins de 6

mètres des vapeurs explosives.

6) Attention: La pression du produit que l’on pulvérise peut produire une

charge électrostatique. Mettre le matériel et l'objet à pulvériser à la terre.

Sur les modèles électriques, le cordon électrique doit être attaché à une

prise de courrant reliée à terre. Le cordon de rallonge doit être à 3 fils. Des

décharges d'électricité statique peuvent se produire si le matériel n'est pas

mis à la terre.

7) Toujours prendre les précautions nécessaires et observer toutes les

consignes de sécurité figurant sur le pot de peinture.

WARNING

Lemmer Air Turbines use a universal motor. This type of motor must not be used in an area contaminated by volatile or

flammable materials since sparking can be expected in the normal operation of the motor and may ignite the contami-

nants causing a DANGEROUS EXPLOSION.

When a flammable liquid is sprayed, the turbine must be placed at least 20 feet away from areas where hazardous

concentrations of flammable vapors are likely to occur.

Use additional air hose if necessary to insure that the turbine is operated in a CLEAN, DRY, WELL VENTILATED

AREA.

NEVER PLACE THE TURBINE INSIDE THE SPRAY BOOTH!!

TABLE OF CONTENTS

SAFETY PRECAUTIONS .............................................................................2

SPECIAL SAFETY PRECAUTIONS ............................................................3

INTRODUCTION...........................................................................................4

PRODUCT SPECIFICATIONS......................................................................4

COATING APPLICATIONS ...........................................................................4

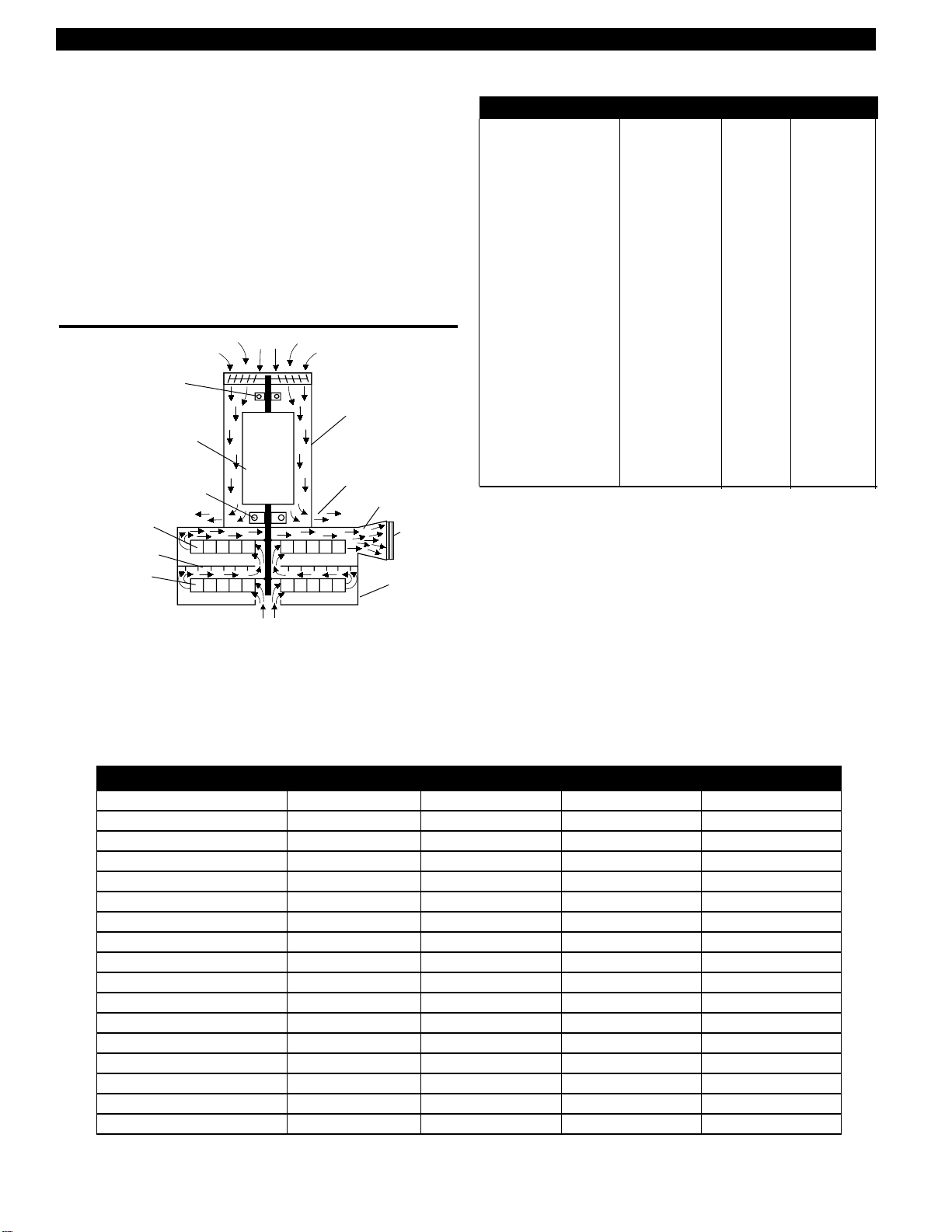

LEMMER TURBINE TECHNICAL FEATURES .............................................4

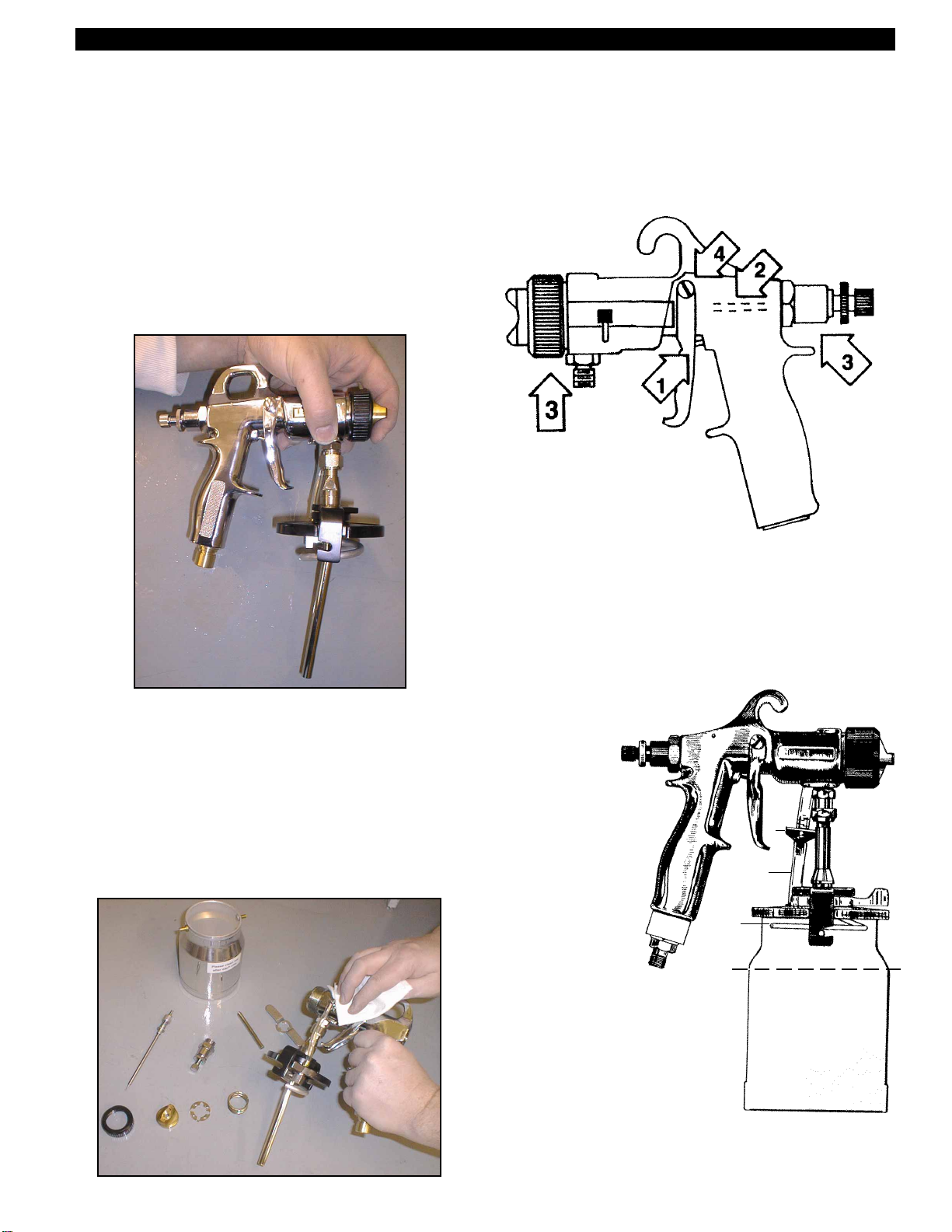

PREPARE FOR OPERATION

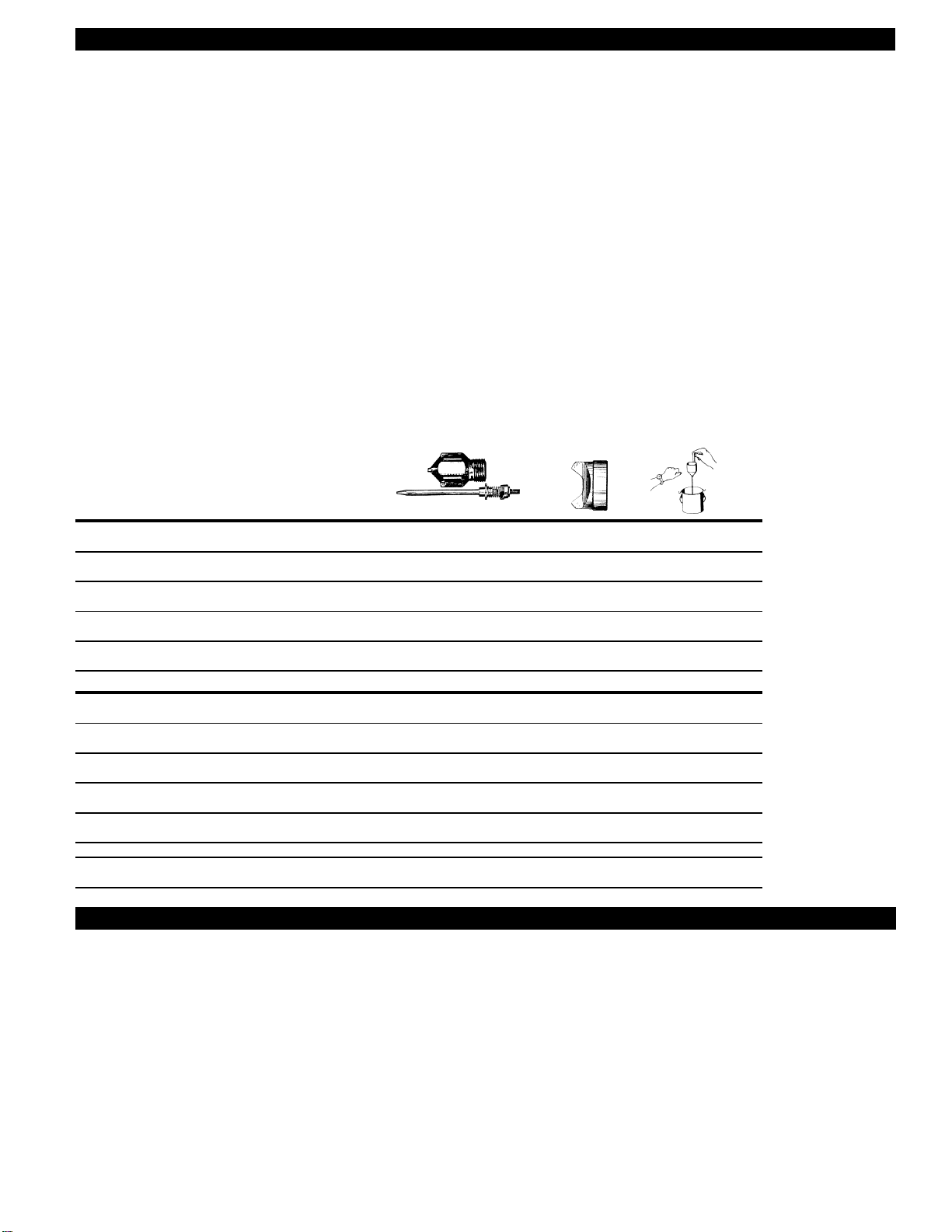

SPRAY GUN CONTROLS...............................................................5

POWER SUPPLY, MOTOR CARE...................................................6

FILTER MAINTENANCE .................................................................6

PAINT STRAINING AND THINNING ...............................................6

SELECTING THE PROPER FLUID SET ......................................................7

VARIABLE SPEED CONTROL ON T-75Q & T-90Q ......................................7

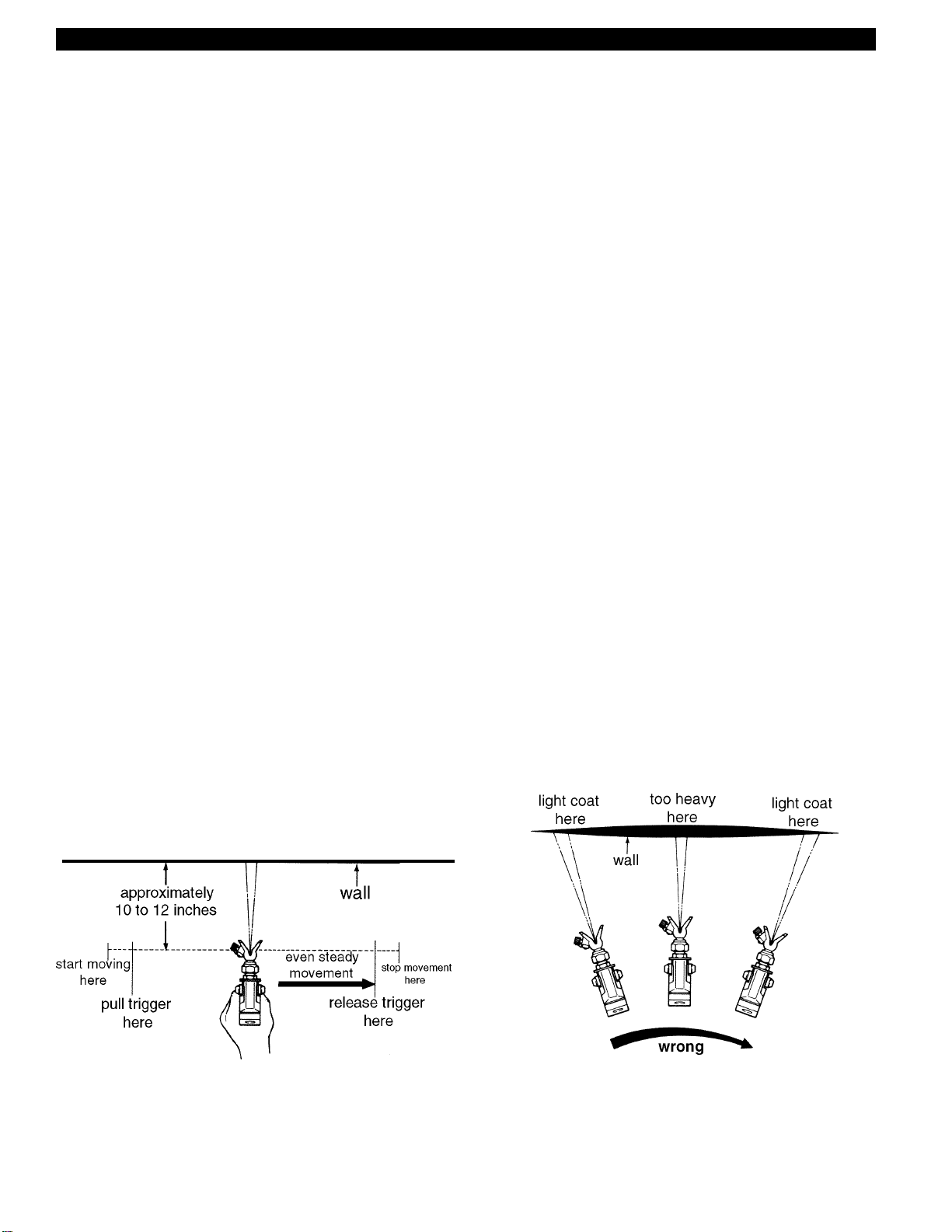

TIPS & TECHNIQUES FOR TURBINE SPRAYING ......................................8

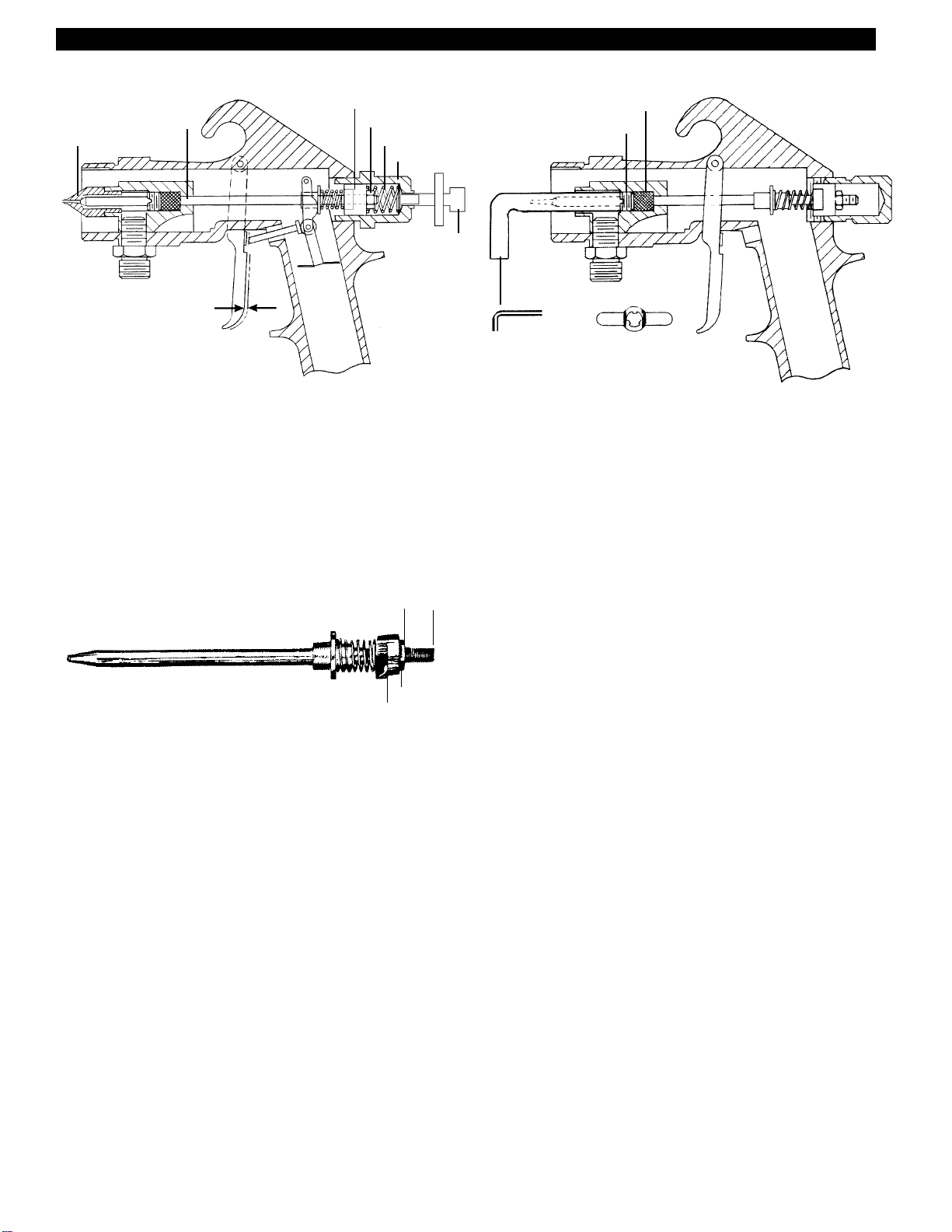

CLEANING, MAINTENANCE & SERVICE........................................... 9 & 10

SPRAYING WITH A PRESSURE FEED SYSTEM .....................................11

OTHER LEMMER PRODUCTS &TURBINE ACCESSORIES .......... 12 & 13

TROUBLESHOOTING ....................................................................... 14 & 15

HOSE CONNECTION DIAGRAM & AIR ACCESSORIES..........................16

PRESSURE POT PARTS LIST ...................................................................17

SERIES 700 HVLP GUN PARTS LIST & DIAGRAM ......................... 18 & 19

A728 HVLP GUN PARTS LIST & DIAGRAM ..............................................20

T-55Q/T-75Q PARTS LIST & DIAGRAM......................................................21

T-90Q PARTS LIST & DIAGRAM ................................................................22

MINI COMPRESSOR & TURBINE CART PARTS LIST & DIAGRAM.........23

DISTRIBUTION CENTRES ACROSS CANADA.........................................24

LEMMER PAINT SPRAYING EQUIPMENT LIMITED WARRANTY ...........24

SAFETY PRECAUTIONS