8 460989001B

Specifications

Note: For UL installations, refer to section UL Listed Installations.

The LNL-1300-U is for connection to low voltage, class 2 power-limited

circuits only. These specifications are subject to change without notice.

• Primary power:

- 12 to 24 VDC + 10%

- 12 VDC @ 700 mA (includes reader current) nominal

- 24 VDC@ 350 mA (includes reader current) nominal

- 28.7 BTU/hour

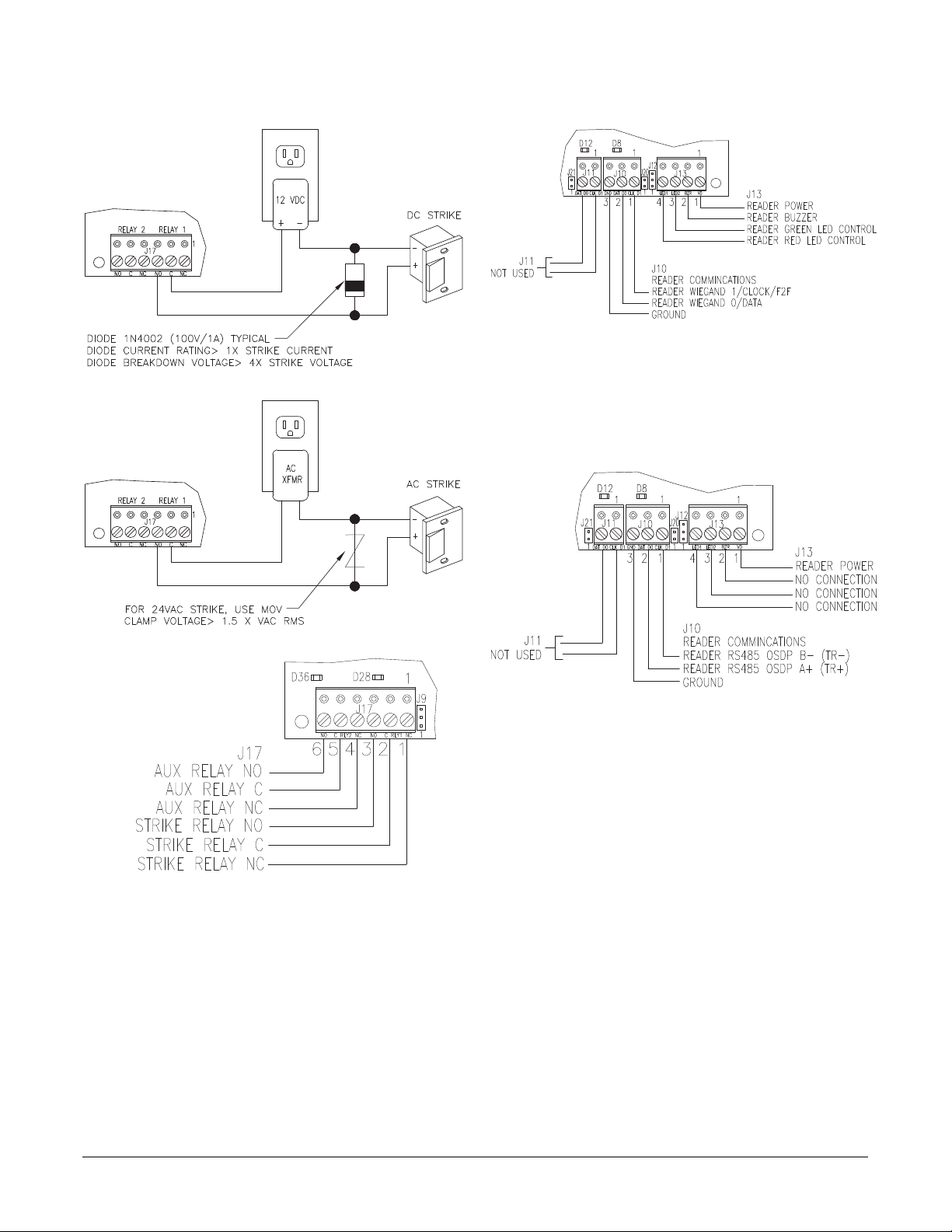

• Outputs: Form-C contacts: Relay 1 and 2 (K1 and K2): 5 A @ 30

VDC

• Inputs:

- Two (2) supervised, End of Line resistors, 1k/1k ohm, 1% 1/4

watt standard

- One (1) unsupervised, dedicated for external (cabinet) tamper

• Reader Interface:

- Reader power: voltage 12 VDC +/-10% (optional 5 VDC +/-5%

jumper selectable, current 400 mA maximum to 50°C, derate to

300 mA for 70°C)

- Reader LED output: open collector type switching (sinking) 10

mA each

- Buzzer output: open collector type switching (sinking) 10 mA

each

- Reader data inputs: 2-wire RS-485, Wiegand, Clock and Data

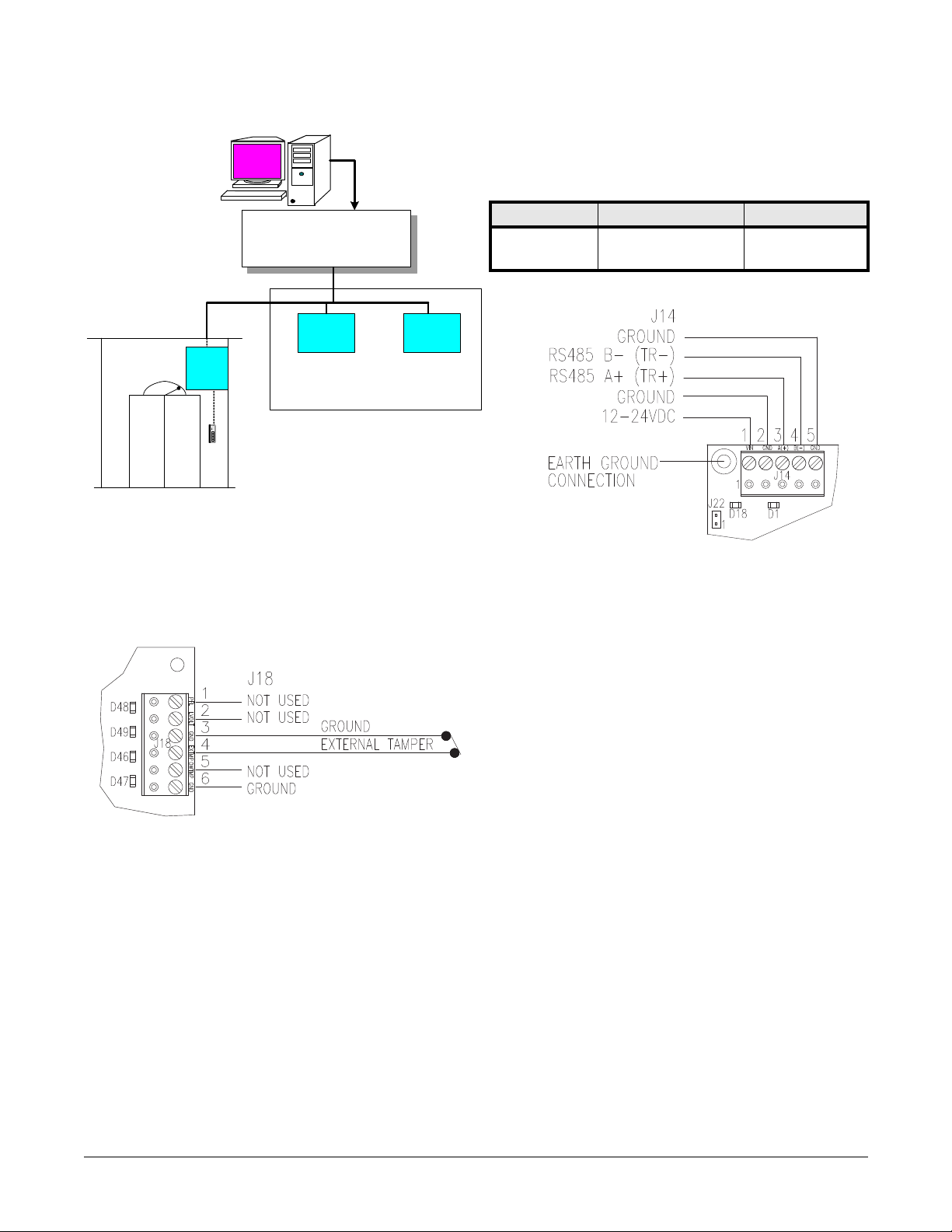

• Communication: RS-485, 2-wire. 2400 to 38400 bps

• Cable requirements:

- Power: 18 AWG, 1 stranded twisted pair

- RS-485 24 AWG, 120 ohm impedance, stranded twisted pair

with shield, 4000 feet (1219 m) maximum

- Alarm Inputs: 1 stranded twisted pair per input, 30 ohms

maximum

- Outputs: As required for the load

- Reader data (Wiegand, Clock and Data): 18 AWG stranded, 6

conductor, 500 feet (150 m) maximum

- Reader data (RS-485): 24 AWG, 120 ohm impedance, stranded

twisted pair with shield, 4000 (1,219 m) maximum

• Mechanical:

- Dimension: 4.75 x 2.75 x 1.25 in. (121 x 70 x 32 mm)

- Weight: 3.5 oz. (100 g) nominal

• Environmental:

- Temperature: -10 to +70°C (14 to 158°F) operating, -40 to

+85C (-40 to 185°F) storage

- Humidity: 10% at 93°C (199°F) non-condensing operating, 10 to

95% at 85°C (185°F) non-condensing storage

• Certifications:

FCC Part 15

FCC compliance: This equipment has been tested and found to comply with

the limits for a Class A digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and,

if not installed and used in accordance with the instruction manual, may

cause harmful interference to radio communications.

ETL 294, s319

UL294, UL1076

C-Tick N22193

CE marking

RoHS

Environmental class: Indoor dry

WEEE

European Union directives: 2002/96/EC (WEEE directive): Products

marked with this symbol cannot be disposed of as unsorted municipal waste

in the European Union. For proper recycling, return this product to your

local supplier upon the purchase of equivalent new equipment, or dispose of

it at designated collection points. For more information see:

www.recyclethis.info.

UL Listed Installations

For UL installations, the following must be observed:

• All field wiring terminals are suitable for single wire only.

• Use 22 AWG minimum for wiring of RS-485, Input I1, and reader

data.

• Do not use Input I2 for UL installations; “Do not supervise for UL.”

• RS-485, Clock & Data reader communications is “Not Evaluated by

UL” and therefore cannot be used in UL installations.

• RS-485 4-wire is “Not Evaluated by UL” and therefore cannot be used

in UL installations.

• The use of AC Strikes is “Not Evaluated by UL” and therefore cannot

be used in UL installations.

• Reader power for UL installations: 300 mA maximum for an operating

temperature range of -10 to +49°C (14 to 120°F).

• Environmental for UL installations:

- Temperature: -10 to +49°C (14 to 120°F) operating

- Humidity: 85+/-5% at 30+/-2°C (86°F)