INDEX

1.

PRODUCT SPECIFICATIONS................................................................................................................................... 3

1.1.

DESCRIPTION ...................................................................................................................................................... 3

1.2.

DESIGNATION ...................................................................................................................................................... 4

1.3.

OPERATING LIMITS ............................................................................................................................................. 4

1.4.

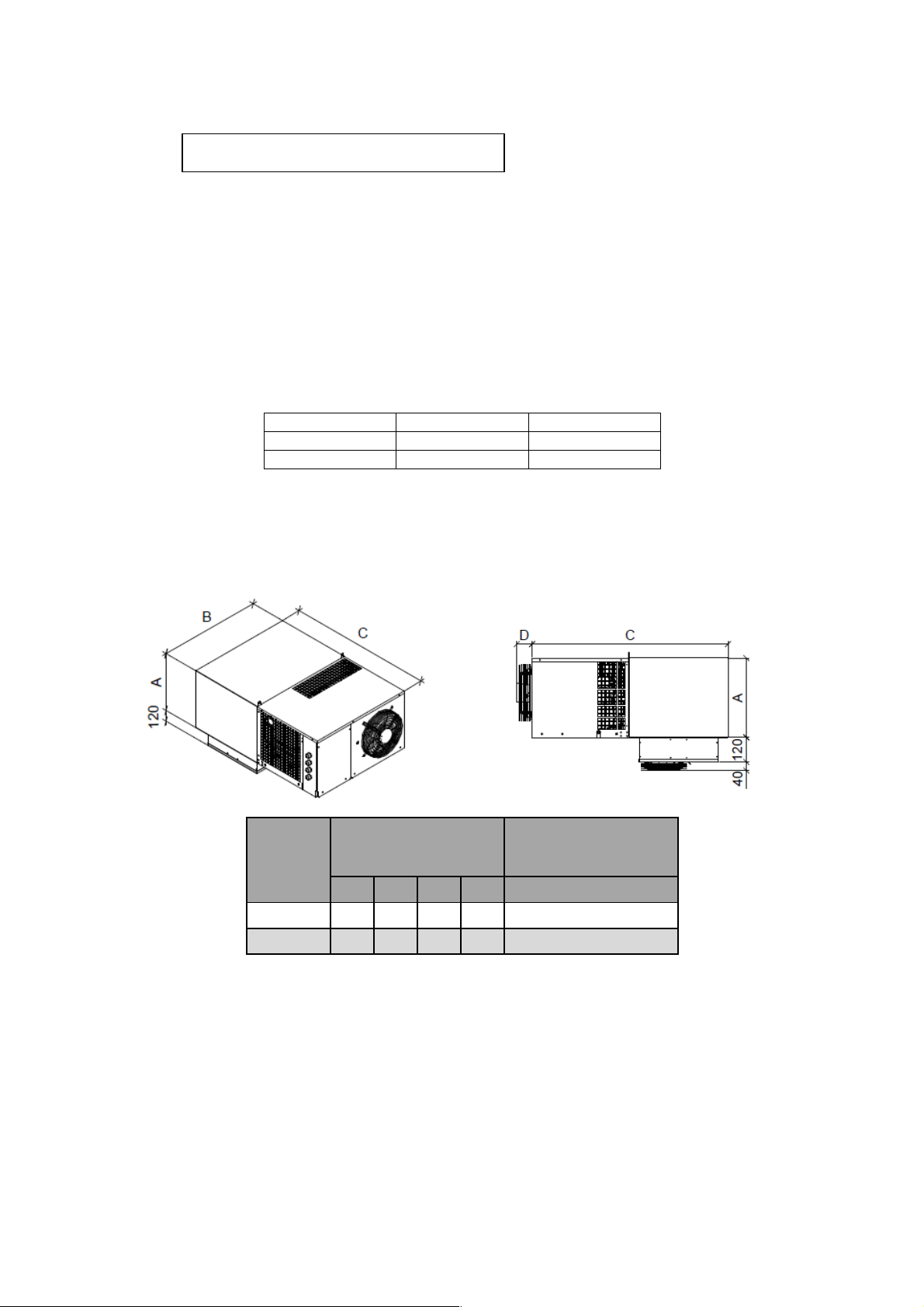

TECHNICAL CHARACTERISTICS AND DIMENSIONS ....................................................................................... 4

1.5.

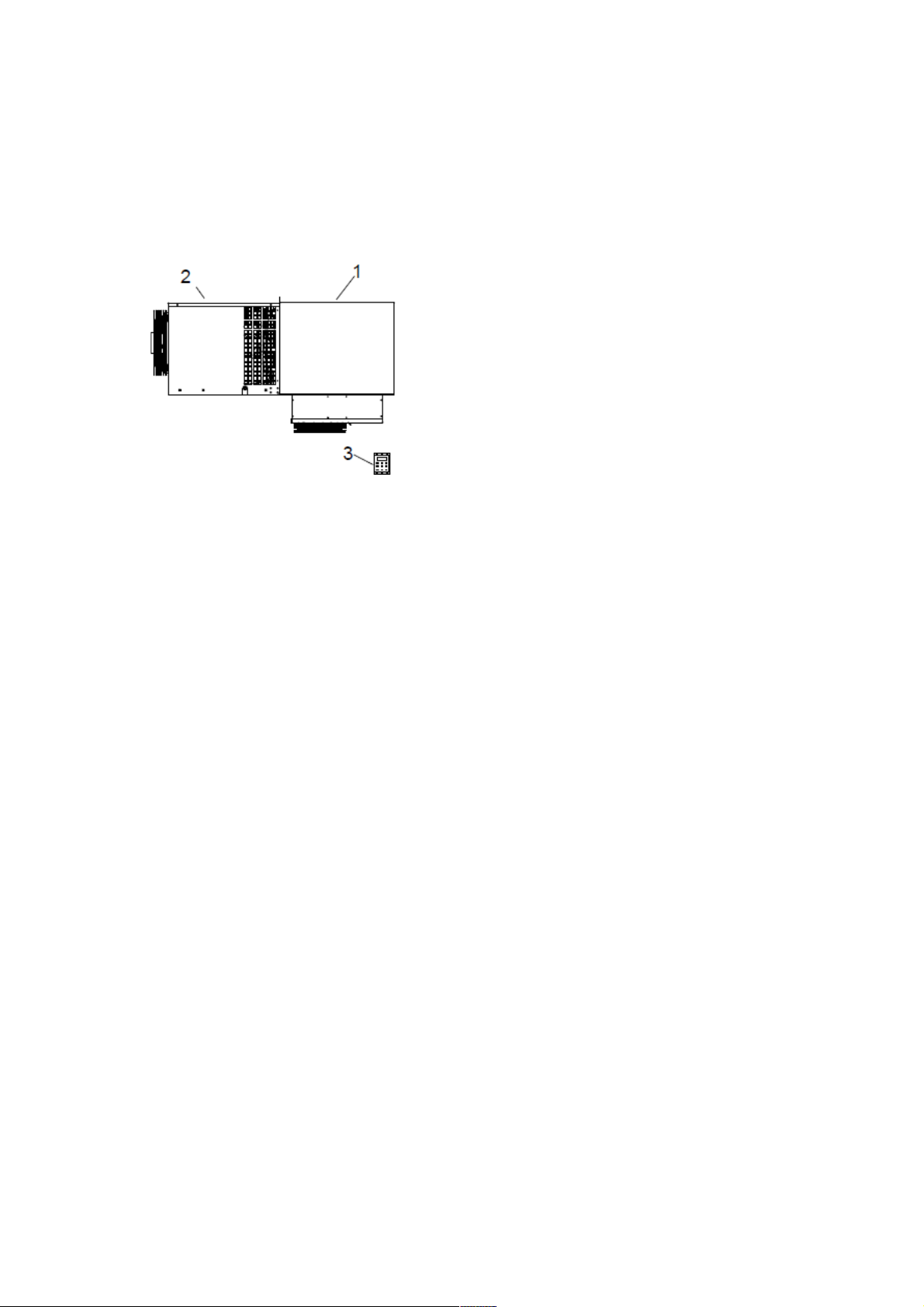

EQUIPMENT DESIGN........................................................................................................................................... 5

2.

UNIT PREPARATION FOR USE ............................................................................................................................... 5

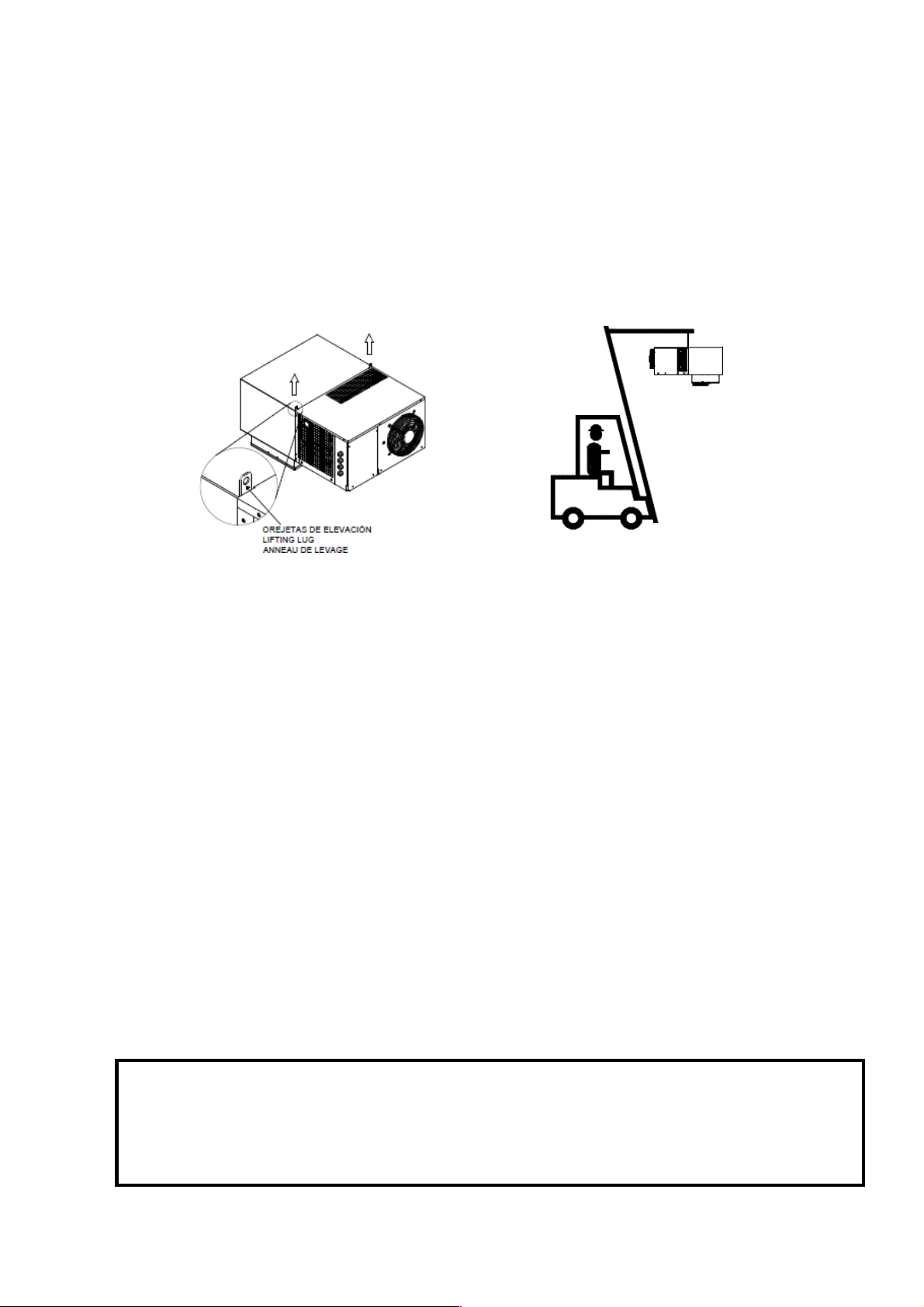

2.1.

TRANSPORT......................................................................................................................................................... 5

2.2.

IMPORTANT SAFETY WARNINGS ...................................................................................................................... 6

2.3.

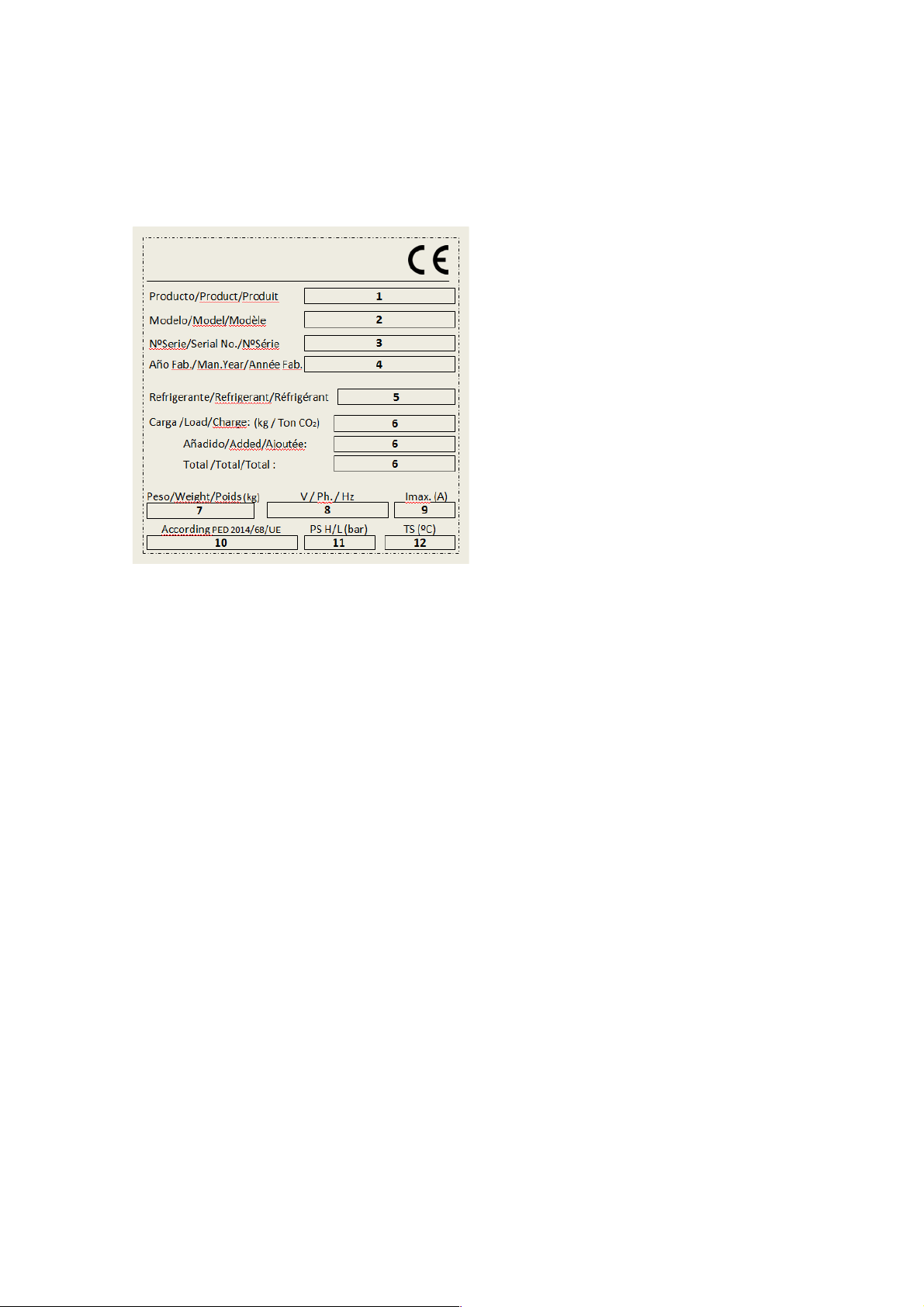

INDICATIONS........................................................................................................................................................ 7

2.4.

INSTALLING THE UNIT......................................................................................................................................... 9

2.5.

COMPULSORY SPACE TO BE LEFT AROUND THE UNIT............................................................................... 10

2.6.

ASSEMBLY.......................................................................................................................................................... 10

2.7.

PROTECTIVE DEVICES AND SAFETY MEASURES ........................................................................................ 11

2.8.

DISPOSING OF PACKAGING............................................................................................................................. 11

2.9.

CONTROLS, ADJUSTMENTS AND CHECKS TO BE MADE............................................................................. 11

3.

OPERATING INSTRUCTIONS ................................................................................................................................ 11

3.1.

CONNECTING THE UNIT TO EXTERNAL POWER SOURCES........................................................................ 11

3.2.

ELECTRICAL POWER CONNECTION ............................................................................................................... 12

3.3.

ADJUSTMENT AND CONTROL.......................................................................................................................... 12

3.4.

COLD ROOM LIGHT ........................................................................................................................................... 13

3.5.

CONTROL DEVICE ............................................................................................................................................. 13

3.6.

CONTROL FUNCTIONS ..................................................................................................................................... 14

3.7.

INDICATOR LIGHTS ........................................................................................................................................... 15

3.8.

ALARM SIGNALS ................................................................................................................................................ 15

3.9.

RESETTING THE ALARMS................................................................................................................................. 15

3.10.

PAL/CA ALARM................................................................................................................................................... 16

3.11. P1, P2, P3, P4 ALARM ........................................................................................................................................ 18

3.12.

dA ALARM ........................................................................................................................................................... 19

3.13.

COMPRESSOR ALARM DOES NOT START ..................................................................................................... 19

3.14.

PARAMETER LIST .............................................................................................................................................. 20

3.15.

EXTERNAL COMMUNICATION.......................................................................................................................... 20

3.16.

STARTING UP THE UNIT ................................................................................................................................... 21

3.17.

DIAGRAM OF THE UNIT ELECTRICAL SYSTEM.............................................................................................. 21

4.

MAINTENANCE AND CLEANING ........................................................................................................................... 21

4.1.

MAINTENANCE AND REPAIR OF THE UNIT .................................................................................................... 21

4.2.

ORDINARY MAINTENANCE............................................................................................................................... 22

4.3.

PERIODICAL AND PREVENTIVE MAINTENANCE............................................................................................ 22

4.4.

SERVICING TO BE CARRIED OUT BY QUALIFIED STAFF ............................................................................. 22

4.5.

TECHNICAL PROBLEMS.................................................................................................................................... 23

4.6.

FAILURE ANALYSIS ........................................................................................................................................... 24

4.7.

HOW TO ORDER SPARE PARTS ...................................................................................................................... 25

4.8.

SCRAPPING THE UNIT ...................................................................................................................................... 25