Page 10

Check sensors by measuring resistance (ohms)

through the sensors with the wires disconnected

from the control (unit not running). The sensor wires

are not olarity sensitive. Table 3 shows winding

tem erature sensor resistance values which will

cause the TSC to lock out. When unit is o erating

normally, resistance through the sensors should be

below the tri value shown in table 3.

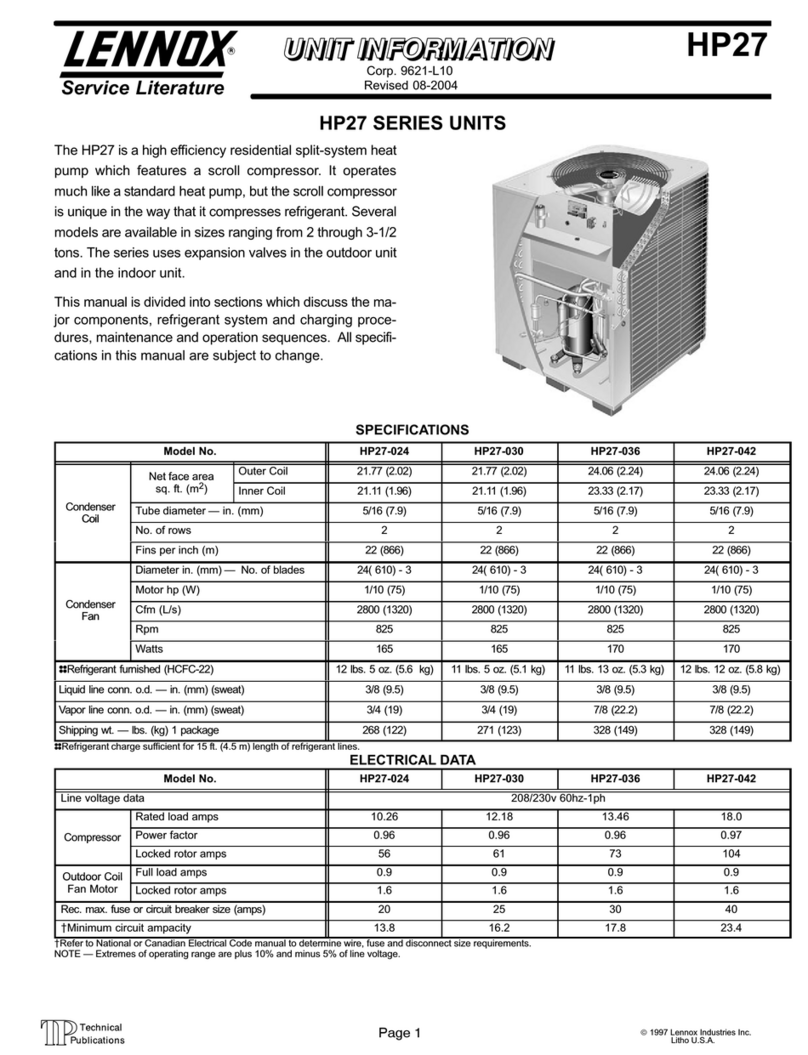

TABLE 3

Compressor Winding

Temperat re Sensor

Trip Ohms

Temp. Rise

Reset Ohms

Temp. Fall

TSC5 Copeland Compressor 25K to 35K 8.4K to 10K

The control can be checked by com aring the reĆ

sistance measured through the sensors to the

voltage measured across the sensor terminals

with the unit running. Table 4 shows voltage meaĆ

sured across twoĆs eed control terminals S1 and

S2 with the com ressor running.

Reset

Range

TABLE 4

Resistance Thro gh

Compressor Winding

Temperat re Sensor

KĆohms (ohms x 1000)

Voltage Across TSC5

compressor sensor terminals

with Unit R nning DC Volts

0

1.0

5.5

6.9

8.4

10.0

16.0

20.0

24.0

25.0

30.0

35.0

Trip

Range

+-

DC volts

Measured with unit running.

COMPRESSOR WINDING SENSOR

OPERATING RANGE

0

1.70 - 1.82

6.07 - 6.48

6.86 - 7.33

7.55 - 8.07

8.16 - 8.72

9.69 - 10.36

10.34 - 11.05

10.82 - 11.57

10.93 - 11.68

11.35 - 12.14

11.68 - 12.48

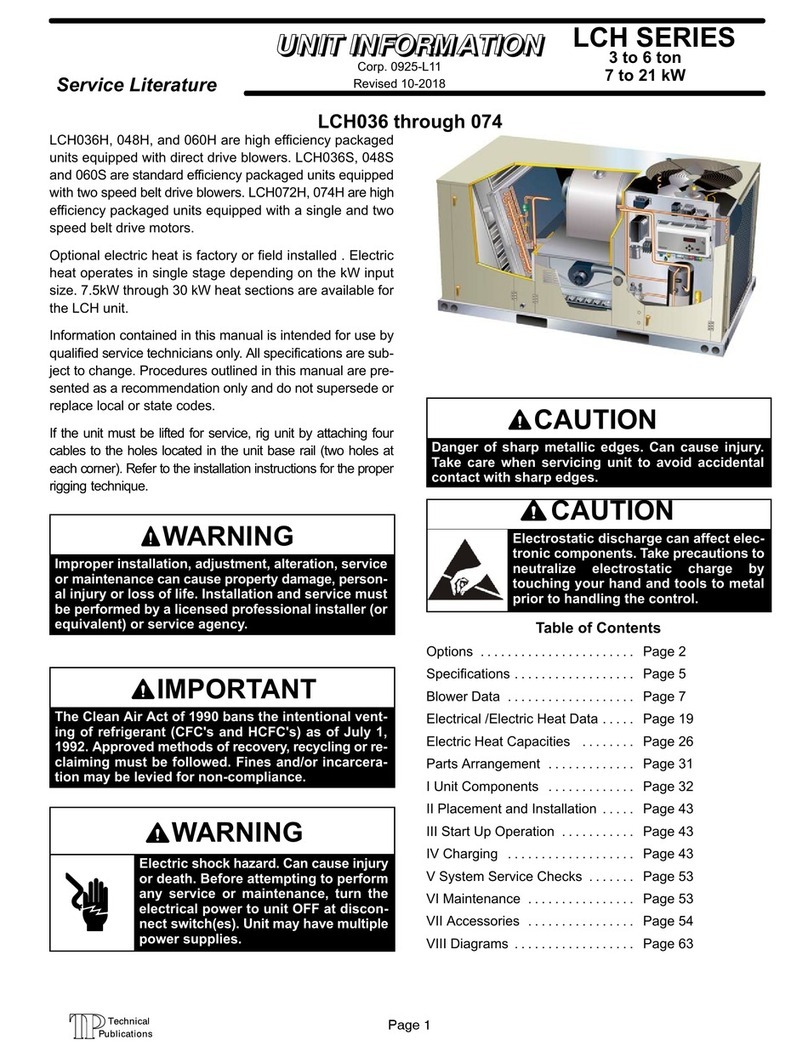

MODE SELECTION JUMPERS

The control has six mode selection j mpers for selection of

operating modes and problem code recall or test. Choose

one of the first fo r modes for operation.

Normal: Normal operation (defa lt mode). Unit

r ns on high or low speed as the indoor

thermostat load demands.

Latch 1: After high speed demand is met, the nit

remains in high speed ntil the low speed

demand is satisfied.

Latch 2: After the nit operates in low speed for 15

min tes consec tively, it switches to high

speed ntil low speed demand is satisfied.

Latch 3: After the nit operates in low speed for 30

min tes consec tively, it switches to high

speed ntil low speed demand is satisfied.

Recall: Used in conj nction with the bypass

b tton to recall the stored problem codes.

Test: Used in conj nction with the control

b tton to start test mode.

Latch 2 or 3 modes are recommended in high h midity

areas. If the j mper falls off or is removed, the control will

contin e to operate in the previo sly set mode ntil the

control is reset d e to loss of power, then the control will

defa lt to the Normal mode. The latch feat re does not afĆ

fect the indoor blower operation.

TEST MODE

The control has a test mode. To initiate this mode, move

the j mper to the test position and p sh the control b tton.

The nit will operate in low speed for 10 seconds, t rn off

for ten seconds, then operate in high speed for 10 seĆ

conds. The control will only go into the test mode if there is

no thermostat demand and 5 min tes has elapsed since

the nit ran. The indoor blower does not r n d ring this

mode. The test mode cannot r n more than once every 5

min tes.

LED LIGHTS

Y1 and Y2 lights are connected directly to the inp ts from the

thermostat. They indicate low and high speed demand, reĆ

spectively.

The HI and LO lights are connected directly across the conĆ

tactor coils. They indicate if the high and low speed contactors

are energized.

The HEARTBEAT light is connected to the microcontroller

nit (MCU). It indicates when the control's MCU is operating

correctly, and also when the control is in delay mode. It blinks

at a rate of fo r times a second when the MCU is operating

properly and at a rate of once every two seconds when in the

delay mode (s ch as the 1 or 5 min te delay). If the LED is

contin o sly on or off (ass ming the power is on), the MCU is

not operating properly and the control needs to be replaced.

The D1, D2, D4, and D8 (see fig re 7) diagnostic lights disĆ

play diagnostic codes to aid in nit tro bleshooting. Refer to

Diagnostic Code Table (table 5).

Diagnostic Code Display

A problem code is normally displayed only for the d ration of

the error. There is one exception. D ring a locko t, the code

for the problem ca sing the locko t flashes once a second

even if the problem condition no longer exists. If other probĆ

lems occ r d ring a locko t condition, the codes for those

problems will be saved in memory, b t not displayed. The

stored problem codes are displayed by recalling them from

memory. The diagnostic codes can be reĆdisplayed by setting

the j mper to the recall position. The stored codes are disĆ

played by p shing the p sh b tton. As previo sly mentioned,

the p sh b tton is sed to bypass the fiveĆmin te delay and to

initiate the test mode. In addition, the b tton is sed to step

back thro gh the stored diagnostic codes and erase the diagĆ

nostic code memory. Diagnostic codes are recalled in the

reverse order of act al occ rrence. Each s bseq ent b tton