OPERATOR'S MANUAL G E L 1 0 4

C o n t e n t s

1 Introduction................................................................................................ 1

1.1 Fundamental safety instructions.............................................................1

1.2 Designated use ......................................................................................2

1.3 Guarantee, liability and copyright...........................................................2

2 Control elements........................................................................................ 3

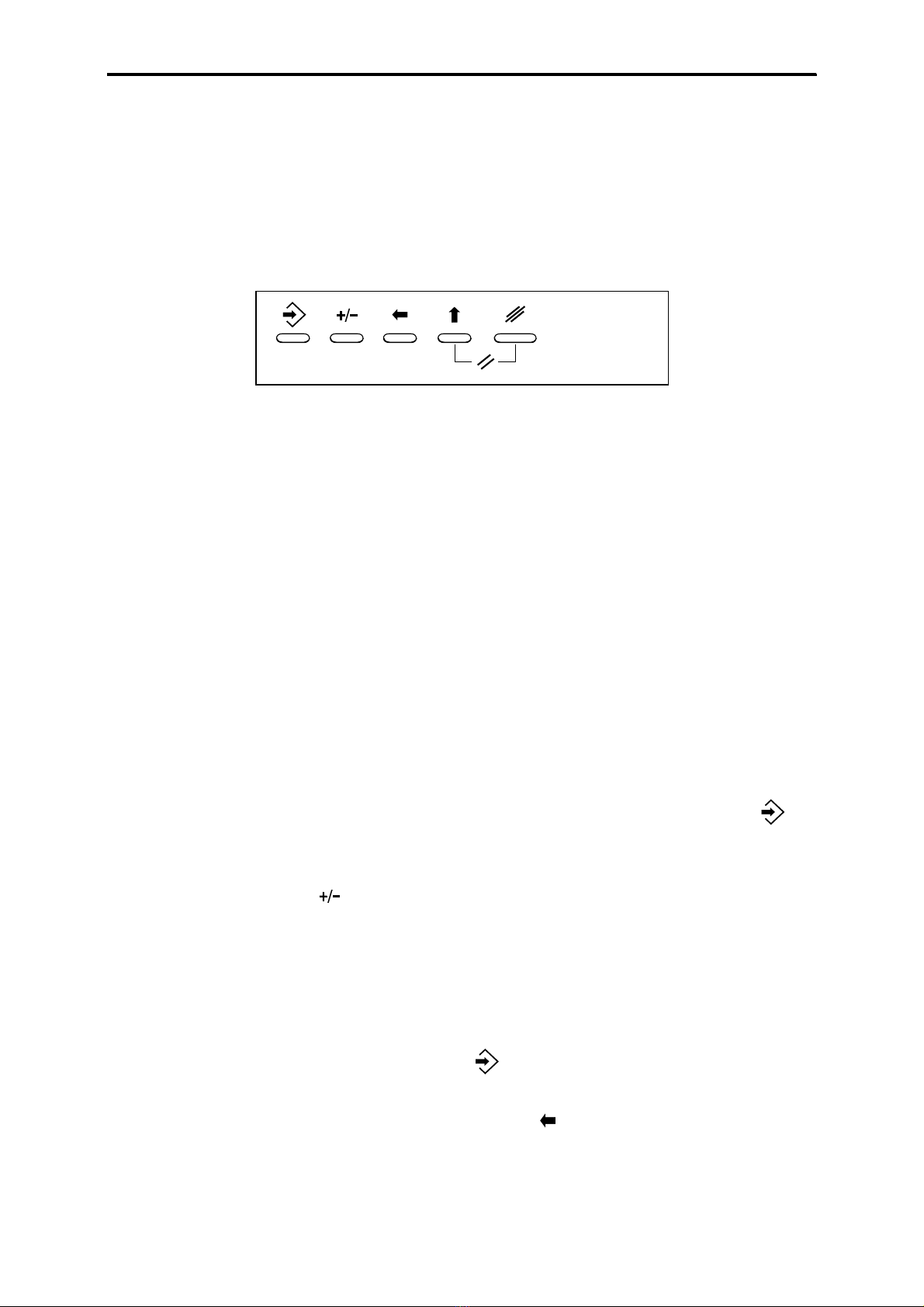

2.1 Keyboard................................................................................................3

2.2 Display....................................................................................................4

3 Programming.............................................................................................. 5

3.1 Operating parameters ............................................................................5

3.1.1 Preselections 1 (P1) and 2 (P2).............................................................6

3.1.2 Set value (SET)......................................................................................6

3.2 Display parameters ................................................................................6

3.2.1 Prescaler (PSC) .....................................................................................6

3.2.2 Decimal point..........................................................................................7

3.3 System parameters................................................................................7

4 Control signals......................................................................................... 10

4.1 Count inputs

Input A

and

Input B

........................................................10

4.2

Reset

....................................................................................................10

4.3 Count gate

Inhibit

................................................................................10

4.4 Display

Hold

.........................................................................................11

4.5

Keylock

.................................................................................................11

4.6 Outputs

Out1, Out2

............................................................................11

5 Assembly, commissioning, diagnosis of errors................................... 13

5.1 Assembly instructions...........................................................................13

5.2 Commissioning.....................................................................................13

5.3 Diagnosis of errors...............................................................................14

6 Technical specification ........................................................................... 15

6.1 Mechanical data...................................................................................15

6.2 Electrical data.......................................................................................15

6.3 Environmental conditions.....................................................................17

6.4 Type code.............................................................................................17

6.5 Dimensions...........................................................................................18

7 Pin layout.................................................................................................. 19