Silver+ Locomotive decoder 9

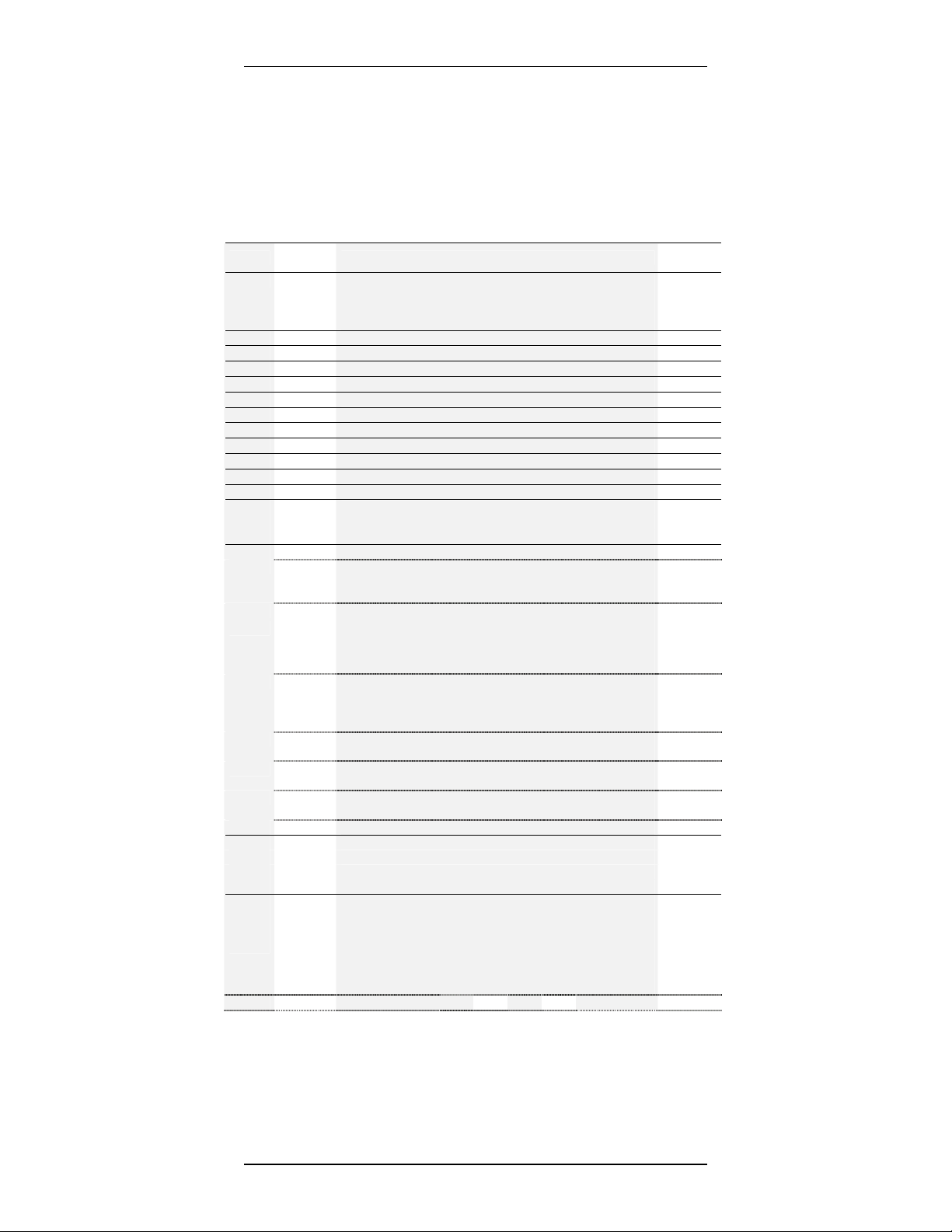

33 0-31 F0 forward 1 2 4 8 16 1

34 0-31 F0 backward 1 2 4 8 16 2

35 0-31 Function 1

forward 1 2 4 8 16 4

36 0-31 Function 2 1 2 4 8 16 8

37 0-31 Function 3 1 2 4 8 16 0

38 0-31 Function 4 1 2 4 8 16 0

39 0-31 Function 5 1 2 4 8 16 16

40 0-31 Function 6 1 2 4 8 16 0

41 0-31 Function 7 1 2 4 8 16 0

42 0-31 Function 8 1 2 4 8 16 0

43 0-31 Function 9 1 2 4 8 16 0

44 0-31 Function 10 1 2 4 8 16 0

45 0-31 Function 11 1 2 4 8 16 0

46 0-31 Function 12 1 2 4 8 16 0

47 0-31 Function 1

backward 1 2 4 8 16 4

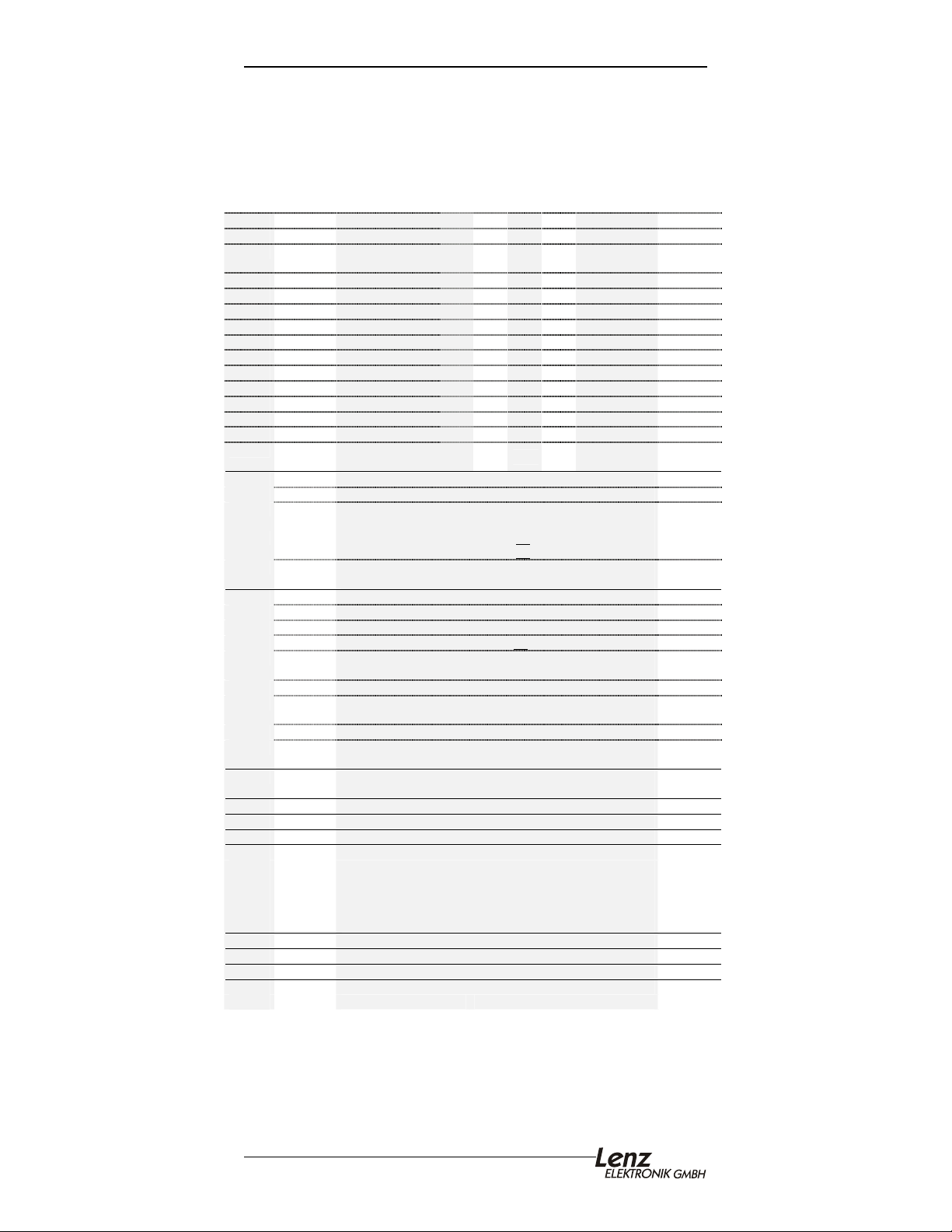

50 Bit Motor configuration 0 (dec)

1-4 (0-3) Select motor type 0-5, enter as decimal number

6 (5) 0 = Normal Back EMF Control

1 = Back EMF control for high efficiency motors

0

7 (6) 0 = Back EMF control switched on

1 = Back EMF control switched off

0

8 (7) 0 = High-frequency motor control (approx. 23 kHz)

1 = Low-frequency motor control (approx. 19 Hz)

0

51 Bit Braking configuration 0 (dec)

1 (0) 1 = Constant braking distance with ABC activated 0

2 (1) 1 = ABC activated 0

3 (2) 1 = ABC direction-dependency deactivated 0

4 (3) 1 = Activate push-pull operation without intermediate

stop

0

5 (4) 1 = Activate push-pull operation with intermediate stop 0

6 (5) 1 = Stopping with DC independent of the polarity (only if

Bit 3 is deleted in CV29).

0

7 (6) Not used

8 (7) 1 = Constant braking distance with speed step 0

activated

52 0-255 Braking distance with activated constant braking

distance

50

53 0-255 Slow approach with ABC 48

54 0-255 Stopping time in push-pull operation, 1 to 256 sec 4

55 0-255 Sets brightness at function outputs A 255=max 255

56 0-255 Sets brightness at function outputs B 255=max 255

57..59

61

64

Function mapping for special effects

Each bit of the CV stands for a function of the digital

system: Bit 1(0) for function 1, Bit 2(1) for function 2 and

so on up to Bit 8(7) for function 8. If you wish to allocate

a function to the dimming, the respective bit must be set.

57 0-255 Mapping of Dimming for Function-Outputs A to D 0

58 0-255 Switching speed (factory setting F3) 4

59 0-255 Switching off the delay (factory setting F4) 8

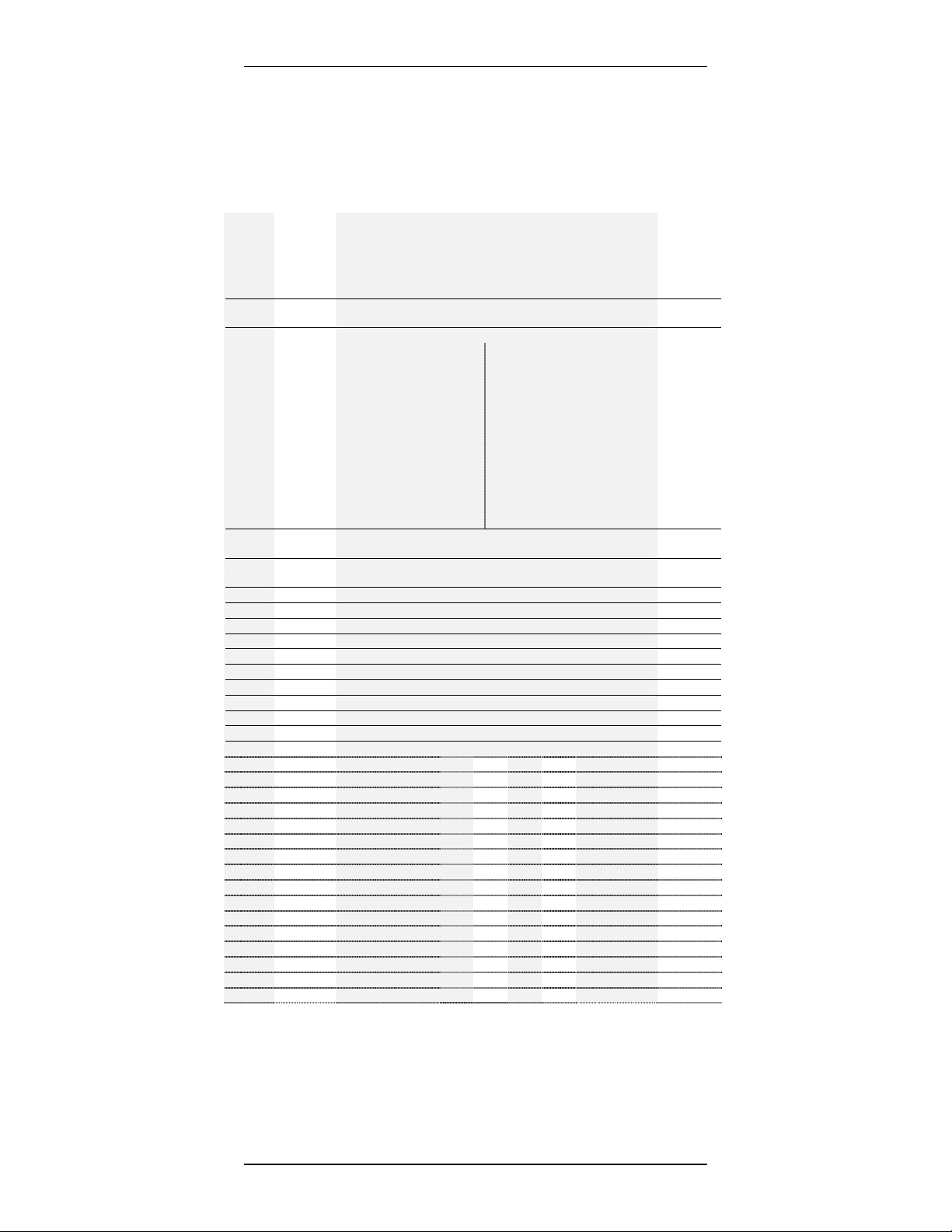

60 0-255 Lighting effect at function outputs A and B: 0

The tens digit for The units digit of the value