2 Friedrich Leutert GmbH & Co. KG

Booster Station - Operating Instructions

Contents

1 Basic Information...............................................................................4

1.1 Information about the Instructions............................................4

1.2 Other Applicable Documents....................................................4

1.3 Warranty and Liability ...............................................................4

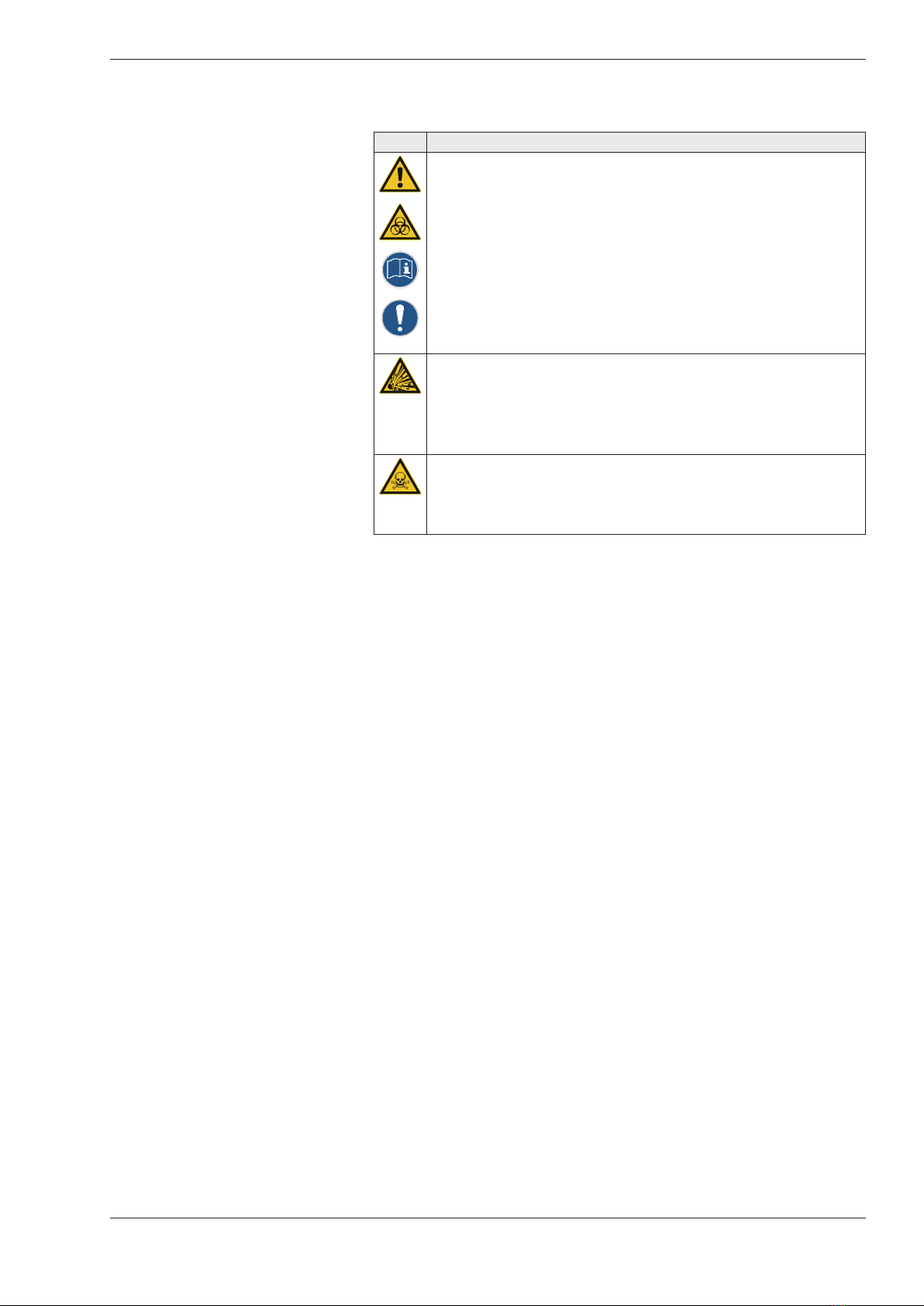

1.4 Explanation of Symbols 1..........................................................5

1.5 Explanation of Symbols 2..........................................................6

2 Basic Safety Information.....................................................................7

2.1 Standards and Directives...........................................................7

2.2 Intended Use ............................................................................7

2.3 Foreseeable Misuse...................................................................7

2.4 Personal Protective Equipment..................................................7

2.5 Hazards that may emanate from the System .............................8

2.6 Basic Safety Measures.............................................................10

2.7 Requirements on Specialist Personnel...................................... 11

3 Technical Data ................................................................................. 12

3.1 Features..................................................................................12

3.2 Specifications Booster Station .................................................12

3.3 Specifications Gas Booster ......................................................13

3.4 Fluid Diagram .........................................................................14

3.5 Dimension Drawing ................................................................15

3.6 Performance Graph ................................................................16

4 Commissioning the System .............................................................. 17

4.1 Safety Guidelines....................................................................17

4.2 Requirements on the Installation Location...............................18

4.3 Minimum clearance ................................................................18

4.4 Supply lines ............................................................................18

4.5 Operating materials ................................................................19

4.5.1 Drive Fluid ..................................................................19

4.5.2 Gas Quality ................................................................19

4.6 Valve adjustment ....................................................................19

4.7 Initial start-up and re-start / operation........................................19

5 Technical Description .......................................................................20

5.1 Essential Components.............................................................20

5.2 Connections ...........................................................................20

5.3 Operator Panel .......................................................................21

5.4 Functional Description ............................................................21

5.4.1 Drive Pressure Supply..................................................21

5.4.2 Fluid Supply / Gas Supply............................................22

5.4.3 Pressure Generation ...................................................22

5.4.4 Discharging ................................................................22