MSI-s 9

SPANISCH ITALIENISCH FRANZÖSISCH ENGLISCH DEUTSCH

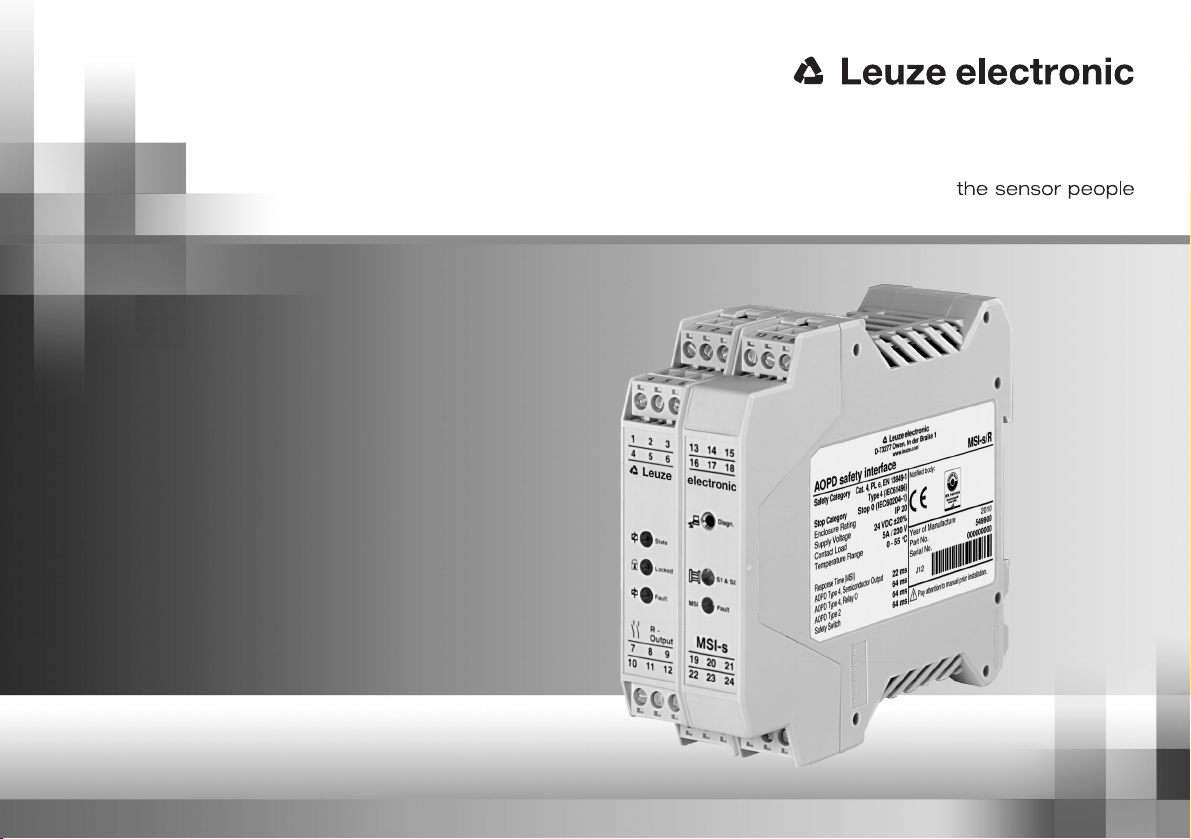

• The Safety Interface Device is used in combination

with one or more Multiple Light Beam Safety Devices

or Safety Light Curtains to safeguard danger or hazard

areas.

• The control of the machine or system that is to be

safeguarded must be electrically influenceable. A

switch-off command initiated by an MSI must result in

an immediate shutdown of the dangerous movement.

• The "Reset" acknowledgment button for unlocking the

start/restart interlock must be mounted in such a way

that the entire danger zone can be seen from its

mounting location.

• Message outputs (state outputs) must not be used for

switching safety-relevant signals.

• The Safety Interface Device is designed for installation

in a cabinet or a protective housing with a protection

rating of at least IP 54.

• The 24 V DC ±20% power supply must guarantee safe

isolation from the mains voltage and be able to bridge

a power outage period of 20 ms.

• Depending on external wiring, dangerous voltages may

be present at the switching outputs. In addition to the

power supply, these must be switched off and safe-

guarded against being switched back on prior to all

work on the MSI-s.

• These operating instructions must be included with the

documentation of the machine on which the protective

device is installed so that they are available to the

operator at all times.

• In the event of changes to the MSI-s, all warranty

claims against the manufacturer of the Safety Interface

Device are rendered void.

• The safety distance between the AOPD and the point

of operation is to be maintained. It is calculated accor-

ding to the formulas for machine-specific C standards

or given in the general B1 standard ISO 13855. Both

the reaction time of the Test Monitoring Unit and the

braking time of the machine must be taken into ac-

count.

• Two switching contacts must always be looped into the

switch-off circuit of the machine. To prevent welding,

relay switching contacts must be fused/protected exter-

nally according to the technical data.

• The Safety Interface Device must be exchanged after a

maximum of 20 years. Repairs or the exchange of

parts subject to wear and tear do not extend the

service life.

• The Safety Interface Device satisfies the requirements

of safety category 4 acc. to ISO 13849-1. If, however,

an AOPD of a lower safety category is connected, the

total category for the given path of the control cannot

be higher than that of the connected AOPD.

• Cross connections between S1 and S2 are only detec-

ted by the MSI safety device if both time-staggered test

signal outputs, T1 and T2, are used for the connected

protective device(s) with relay output. AODPs of type 4

with safety-relevant transistor outputs and their own

cross circuit monitoring can be directly connected to S1

and S2.