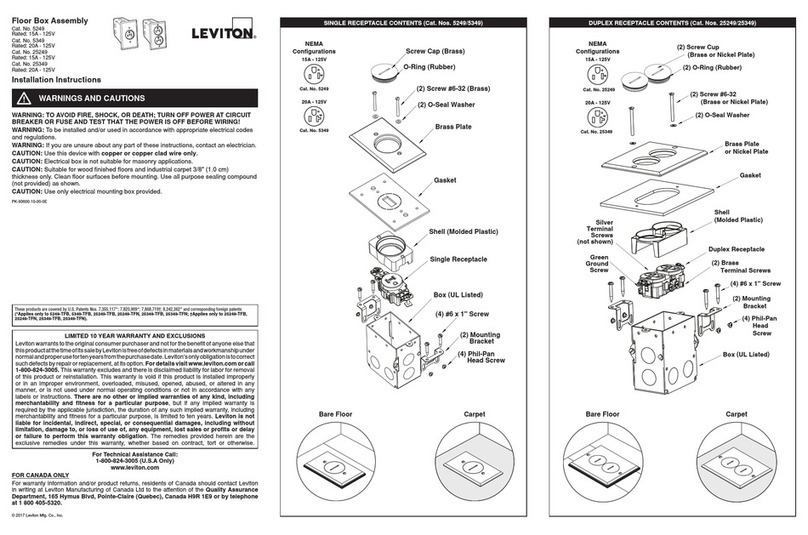

LIMITED 5 YEAR WARRANTY AND EXCLUSIONS

Leviton warrants to the original consumer purchaser and not for the benefit of anyone else that this product at the time of its sale by Leviton is free of defects in materials and workmanship under normal and proper use for five years from the purchase date. Leviton’s only obligation is to correct such defects by repair or replacement, at its option, if within such five year period the product is returned prepaid, with proof

of purchase date, and a description of the problem to Leviton Manufacturing Co., Inc., Att: Quality Assurance Department, 59-25 Little Neck Parkway, Little Neck, New York 11362-2591. This warranty excludes and there is disclaimed liability for labor for removal of this product or reinstallation. This warranty is void if this product is installed improperly or in an improper environment, overloaded, misused,

opened, abused, or altered in any manner, or is not used under normal operating conditions or not in accordance with any labels or instructions. There are no other or implied warranties of any kind, including merchantability and fitness for a particular purpose, but if any implied warranty is required by the applicable jurisdiction, the duration of any such implied warranty, including merchantability and fitness

for a particular purpose, is limited to five years. Leviton is not liable for incidental, indirect, special, or consequential damages, including without limitation, damage to, or loss of use of, any equipment, lost sales or profits or delay or failure to perform this warranty obligation. The remedies provided herein are the exclusive remedies under this warranty, whether based on contract, tort or otherwise.

Testing your Sensor prior to completely mounting in wall box:

NOTE: Dress wires with a bend as

shown in diagram to relieve stress

when mounting device.

Step 6

1. If there is no response from the unit and the LED never blinks or the push button

does not activate the lights 1 1/2 minutes after power is applied, then uninstall

device and verify wiring (Step 5).

2. If the lights constantly stay ON, even when the room is unoccupied:

A. Check the Time setting. See how this time compares to how long the lights

stay ON.

B. Try lowering the Range Control. Rotate the knob counter-clockwise about 30˚.

C. If the problem persists, try reducing again. Note: Do Not reduce so much that

Cat. No. ACP15-CB cannot see normal occupancy.

D. Be sure to use the Blinders to block any unwanted hallway traffic.

E. Check for reflected heat/motion as Sensor Unit may be seeing motion through

a window.

F. Check for adjacent HVAC and/or heater ducts.

TROUBLESHOOTING

DI-000-ACP15-00A

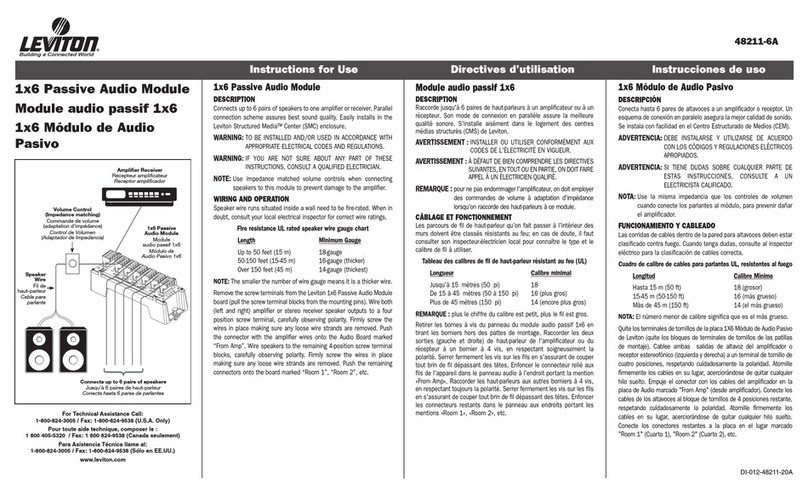

3-Way Wiring with Sensor Remote or Matching Remote

(w/LED) Application:

NOTE: ACP0R sensor remote is depicted.

NOTE: The sensor must be installed in a wall box that has a Load connection.

The remote must be installed in a wall box with a Line Hot connection and a

Neutral connection. A Neutral wire to the remote needs to be added as shown. If

you are unsure about any part of these instructions, consult a qualified electrician.

NOTE: Maximum wire length from sensor to all installed remotes cannot exceed

300 ft (90 m).

WIRING REMOTE (wall box with Line Hot connection):

Connect wires per WIRING DIAGRAM as follows:

• Green or bare copper wire in wall box to Green terminal screw.

• Line Hot (common) wall box wire identified (tagged) when removing old switch

and First Traveler to sensor terminal screw marked “BK”.

• Second Traveler wall box wire from sensor to remote terminal screw marked

“YL/RD” (note wire color). This traveler from the remote must go to the terminal

screw on the sensor marked “YL/RD”.

• Line Neutral wall box wire to remote terminal screw marked “WH”.

WIRING SENSOR (wall box with Load connection):

Connect wires per WIRING DIAGRAM as follows:

• Green or bare copper wire in wall box to Green terminal screw.

• Load wall box wire identified (tagged) when removing old switch to terminal

screw marked “RD”.

• First Traveler Line Hot to terminal screw marked “BK”.

• Remove Red insulating label from terminal screw marked “YL/RD”.

• Second Traveler wall box wire (note color as above) to terminal screw marked

“YL/RD”. This traveler from the sensor must go to the terminal screw on the

remote marked “YL/RD”.

• Line Neutral wall box wire to remote terminal screw marked “WH”.

• Proceed to Step 6.

• Position all wires to provide room in outlet

wall box for device.

• Ensure that the word “TOP” is facing up on

the device strap.

• Partially secure device using long mounting

screws provided.

• Restore power at circuit breaker or fuse.

• Perform the adjustments for the time-out

and blinder settings (refer to Time Delay

and Blinders section).

If necessary, adjust the range control and

the blinders to stop any unwanted activation

of the lights.

NOTE: To avoid PERMANENT DAMAGE to the unit, be careful NOT TO OVERTURN the

control knobs or levers when setting the Sensor. The controls can be accessed by removing

the wallplate (if applicable) and control panel cover (refer to Sensor Features Diagram). Use

a small straight blade screwdriver to adjust knobs and blinder levers.

NOTE: DO NOT press in on blinder levers or use excessive force (refer to Sensor

Features Diagram).

• Attach the Control Panel cover when the desired settings are complete.

If lights still do not turn ON, refer to the TROUBLESHOOTING section.

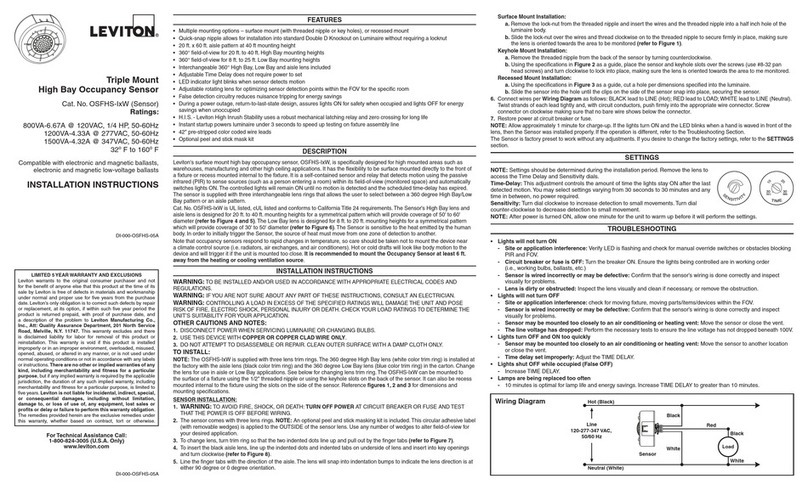

BLINDERS: The blinders can narrow the field-of-view of the device to prevent unwanted

activation from traffic in adjacent space. There are two blinders, and each operate

independently. To operate the blinders, use a small screwdriver to move the blinder adjustment

levers toward or away from the center of the device. The blinder levers are found above the

control knobs and below the text ‘BLINDERS’ on the control panel. With both levers moved

fully towards the center, the field-of-view is narrowed to 32°. With both levers moved fully away

from the center, the field-of-view is at a maximum 180° (refer to Sensor Features Diagram).

TIME-DELAY: Cat. No. ACP15-CB will turn lights ON only when the switch is manually

activated. When motion is no longer detected, the Sensor Unit will wait the selected amount of

time and then turn the lights OFF. This wait time is called ‘time-out’. The “time-out” is selected

from four (4) preset values. Pointing the arrow at one of the markings on the face chooses the

value of time. The following selections are available:

Face Marking Value of Time

(/) Slash Mark 30 second fixed time-out used for performing a walk-test.

1 5 minute time-out

2 15 minute time-out

3 30 minute time-out

The “time-out” is factory preset to thirty (30) minutes. Refer to Sensor Features

Diagram.

NOTE: All time durations mentioned in the instructions are approximate within 10 seconds.

MANUAL ON: The lights need to be manually turned ON by the push-button, and will turn OFF

with the absence of motion or can be manually turned OFF.

RANGE: To decrease detection range and sensitivity, rotate the knob counter-clockwise (refer

to Sensors Feature Diagram). The detection range can be adjusted from 100% down to 36%.

Sensor Mounting:

TURN OFF POWER AT

CIRCUIT BREAKER OR

FUSE.

NOTE: This device must

be installed with the

AcentiTM Alignment Plate.

The Alignment Plate is

packaged with the AcentiTM

Wallplate, which is sold

separately from this

device.

Step 7

OPERATION

Cat. No. ACP15-CB has a push-button switch that will toggle the lights ON and OFF

(refer to diagram). The lights will not turn ON automatically with occupancy. If the

lights are OFF, the lights will turn ON when the button is pressed, and remain ON in the

presence of motion. The Sensor will turn the lights OFF either in the absence of motion

or when the button is pressed. If motion is detected within 30 seconds after the lights

have turned OFF due to absence of motion, the lights will turn back ON. If 30 seconds

expires when lights have turned OFF due to absence of motion, the lights will then have

to be turned ON manually.

NOTE: This feature does not apply when the lights are manually turned off.

NOTE: The Motion Indicator LED will blink every 2 seconds while motion is detected.

Field-of-View (Horizontal)

Wall Surface

Mounting

Screws

(2 places)

Sensor

Alignment Pin

(2 places)

Mounting Screw

(remove if applicable)

Adapter Plate

NOTE: Dress wires with a bend as shown in diagram in order to relieve stress when

mounting device. Ensure tab of Alignment Plate is on bottom.

• If Alignment Plate is temporarily positioned using screw as in

Step 4A, remove screw at this point.

• Position all wires to provide room in outlet wall box for device.

• Ensure that the word “TOP” is facing up on both the alignment

plate and device strap.

• Position device so that the alignment holes fit on alignment pins

as shown. Press device onto Alignment Plate until strap sits flat.

• Align the two star patterned alignment holes of the Adapter Plate

over the two pins of the Alignment Plate. Gently press Adapter

Plate onto Alignment Plate until Adapter Plate sits flat.

• Tighten mounting screws into wall box so that device remains flat

on Alignment Plate.

• CAUTION: DO NOT over-tighten device mounting screws.

Overtightening will cause improper mounting and alignment.

Using a high-torque power screwdriver is not recommended.

Alignment Plate must sit flush on wall

surface.

NOTE: For multi-device applications,

refer to Wallplate Instruction Sheet.

Pin and Alignment

Hole engaged

(2 places)

Wall surface

Wallplate

Notch on bottom

Wallplate Mounting:

Mounting: With notch facing down, press on

Acenti™ wallplate (sold separately).

Removal (if necessary): Using a small

screwdriver, place in notch in bottom of wallplate

and gently lift up to remove.

Step 8

Restore Power:

Restore power at circuit breaker or fuse.

Installation is complete.

Step 9

Lens

Push

Button

LED

Window

Blinders

Control

Panel

Cover

This equipment has been tested and found to comply with the limits for a Class B

Digital Device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential installation.

This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause harmful interference to

radio or television reception, which can be determined by turning the equipment OFF

an ON, the user is encouraged to try to correct the interference by one or more of the

following measures:

• Reorient or relocate the receiving Antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

• Consult the dealer or an experienced radio/tv technician for help.

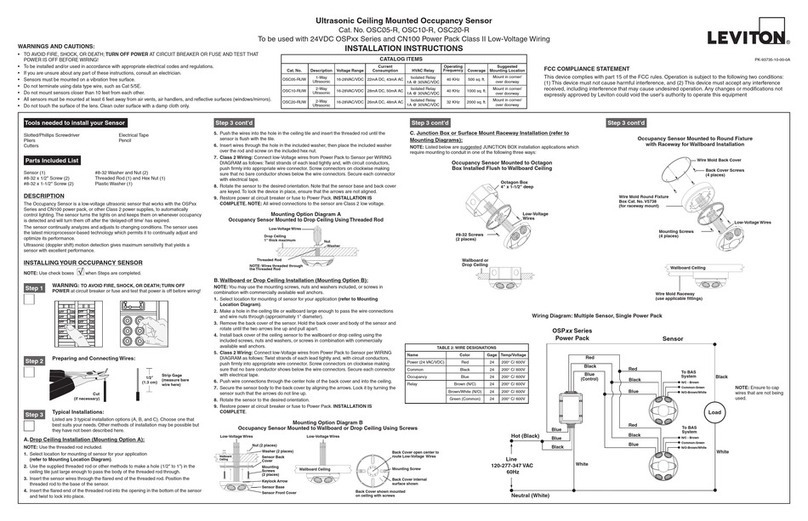

FCC COMPLIANCE STATEMENT