Page 2

MSU-DFX SERIES

Installation Instruction

ERP: IIS00344

03/11/2022 Rev1.0

Manufacturer is not responsible for any injuries due to the improper installation or handling of its products.

Hard Ceiling Flange

NOTES

Installation should be completed by an individual familiar with the construction and operation of the luminaire.

Installation of luminaire must be in accordance with nation and local building and electrical codes.

Carefully read and follow all warnings and instructions before installing or servicing the luminaire.

Instructions do not cover all details and all possible product configurations

Do not restrict luminaire ventilation.

Ensure LED luminaire is not covered with material that will prevent convection or conduction cooling.

Do not exceed luminaire’s maximum ambient temperature.

Ensure LED luminaire has the correct polarity before installation.

Based on maximum voltage restrictions for class 2 circuits in Canadian Electrical Code, the output cannot be accessible. This product has accessible

output terminals. This product complies with this requirement since the installation instruction requires installation in Restricted Access Area.

WARNINGS

Electric shock:

Disconnect or turn off power before installing or servicing luminaire.

All electrical wiring to be completed by a qualified licensed electrician

in accordance with local and National/Canadian Electrical Code.

Ensure supply voltage corresponds with the correct ballast/driver

voltage.

Avoid exposing wiring to metal edges and sharp objects.

Ensure that the luminaire is properly grounded to prevent electric

hazards.

Fire:

Keep flammable and combustible materials away from the light source and/or

lens.

Use correctly rated supply conductors as indicated by product labeling.

Burn:

Allow luminaire to cool before handling luminaire.

Personal Injury:

Wear safety glasses and gloves when handling the luminaire to avoid physical

injury.

Avoid direct eye contact with light source.

Always support the weight of the luminaire.

Note:

The models requires an accurate cutout of the luminaire opening. It is essential that the opening room side edge be flat

to ensure the integrity of the seal.

Use 1-5/8 Unistrut (not included) or equivalent support beams on all four sides above the opening edge. The support struc-

ture should be suitably rigid and secured to support the weight of the luminaire. (Minimum thickness of ceiling and framing

is 1 1/2”, maximum is 2 3/4”).

Only qualified electricians should make the electrical connections and should ensure that all Building and Safety code re-

quirements are observed.

CRU & MD1U when supplied with white + red or white + green LEDs, are to be separately switched externally. Also they

are NOT to be operated simultaneously.

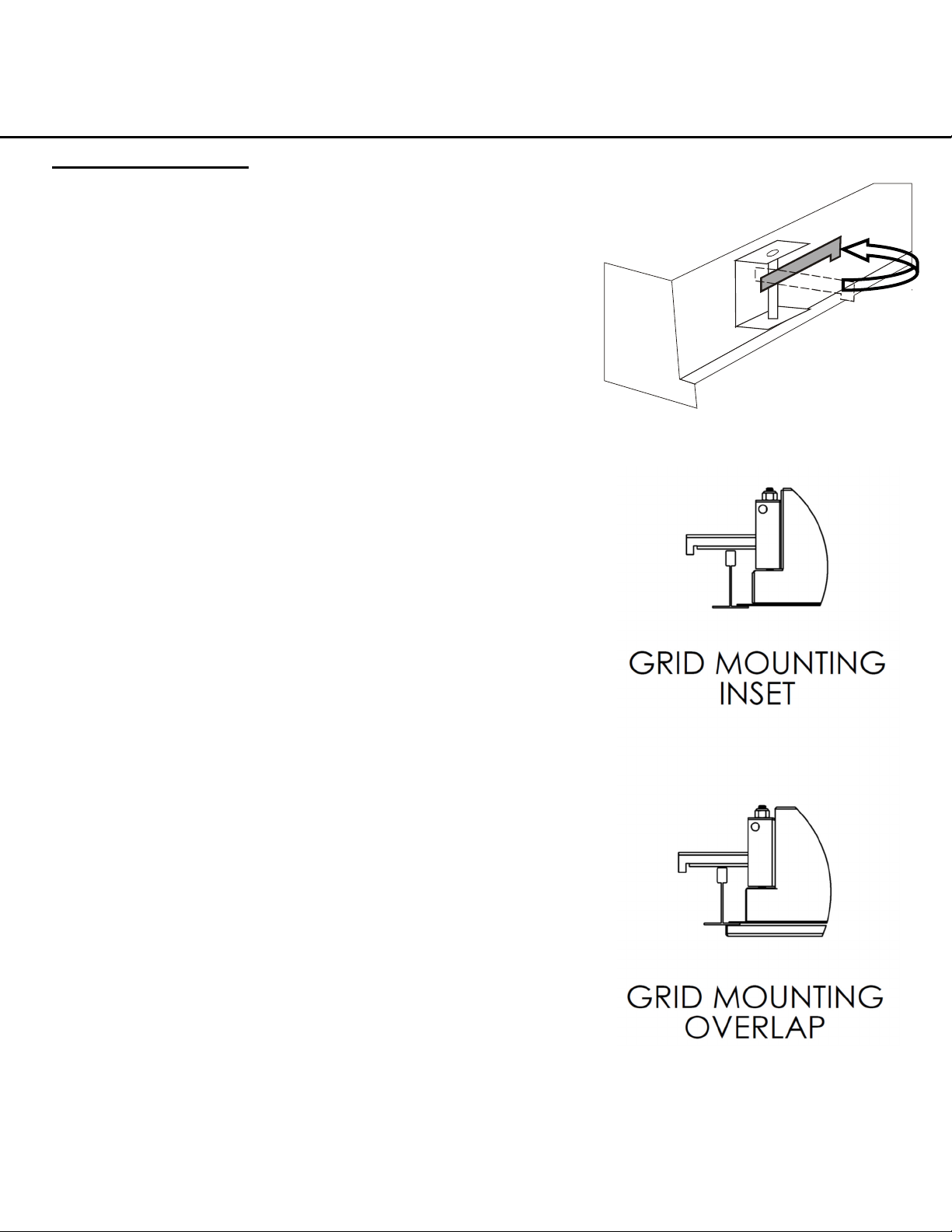

Mounting:

1. Disconnect electrical power intended to be connected to the luminaire.

2. Locate and cut the required opening in the ceiling.

3. Install and secure the required support structure.

4. Remove the lens and door assembly by removing all twelve self-sealing screws from the luminaire.

5. Insert the luminaire into the ceiling then extend the swing-out brackets above the support structure. Tighten all swing-

out brackets to ensure a tight and continuous seal on the room side of the opening.

6. Remove the cover and make the electrical connections to the power supply. Do not remove or use a different power

cord fitting than the one supplied.

7. Replace the cover and install suitable lamps (not supplied).

8. Replace the lens and door assembly with the original self-sealing screws. Tighten to a maximum torque of 10 in-lbs.

Ensure that the door gasket makes a continuous seal to the ceiling surface.

9. Apply power.

See next page for diagram

- Refer to sheet IIS00262 for Gasket Installation.