Table of Contents

1SAFETY PRECAUTIONS...............................................................................................................................................................3

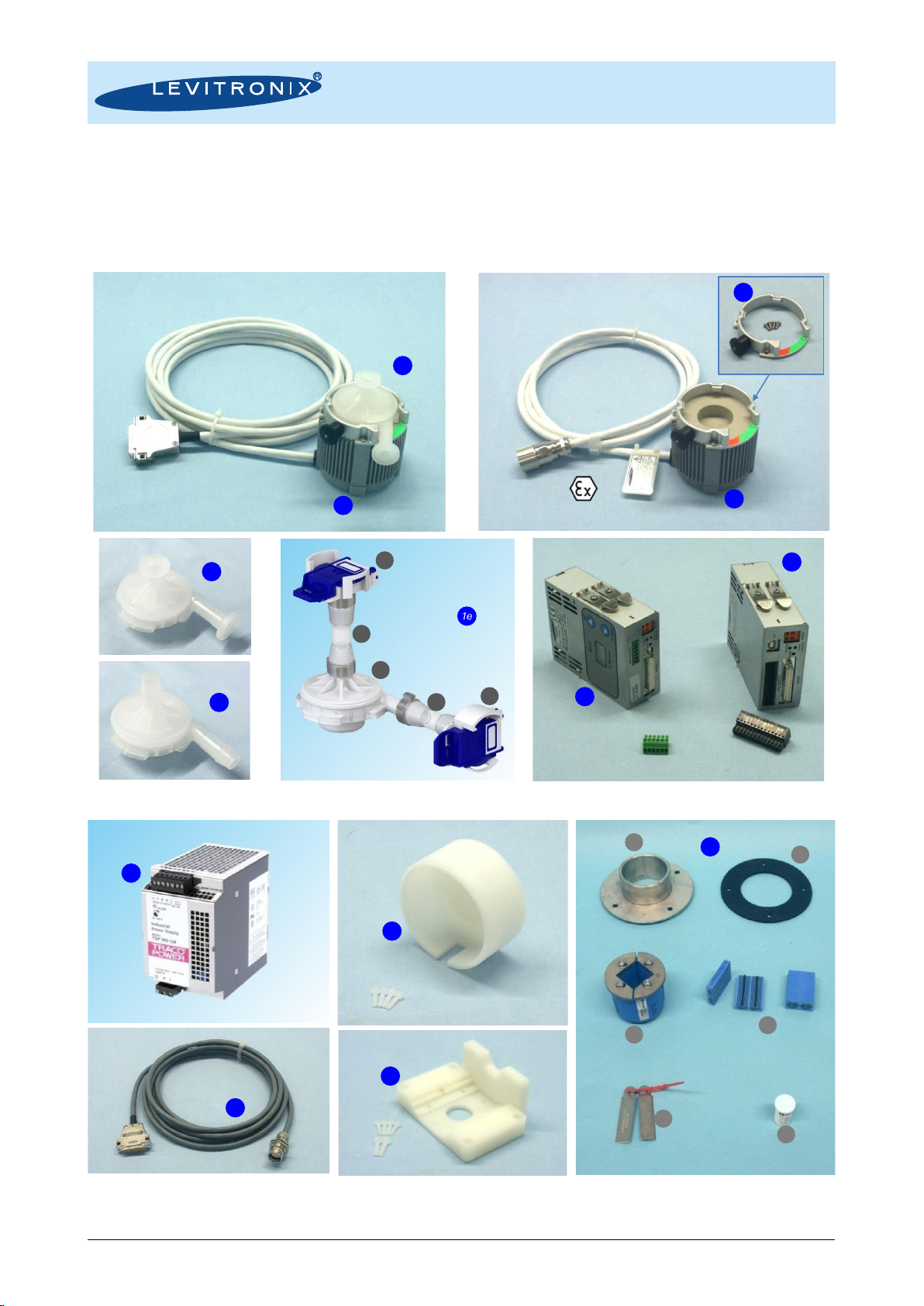

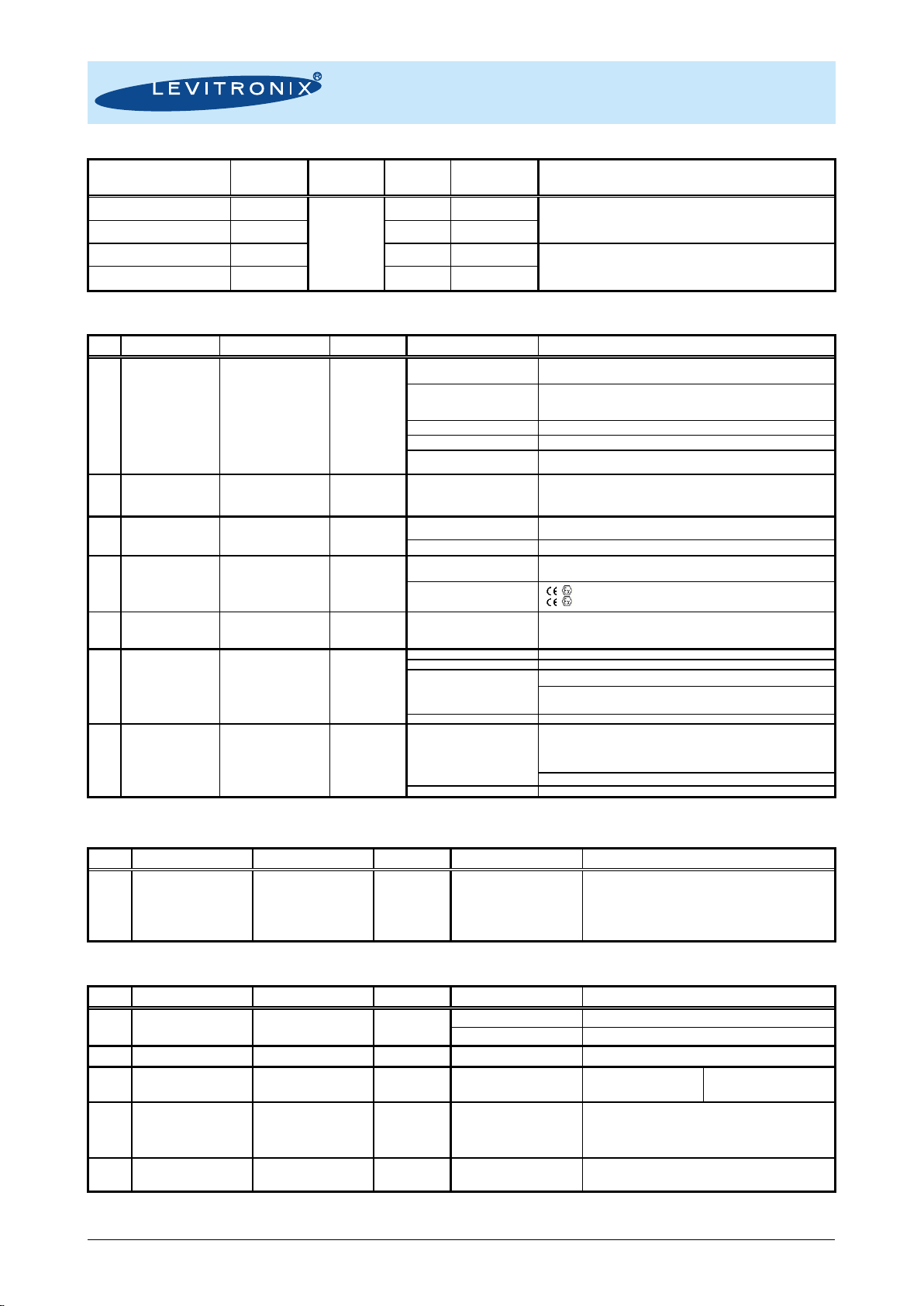

2SPECIFICATIONS..........................................................................................................................................................................4

2.1 Specification of Components.................................................................................................................................................4

2.2 System Overview and General Specification.........................................................................................................................6

2.3 General Environmental Conditions........................................................................................................................................7

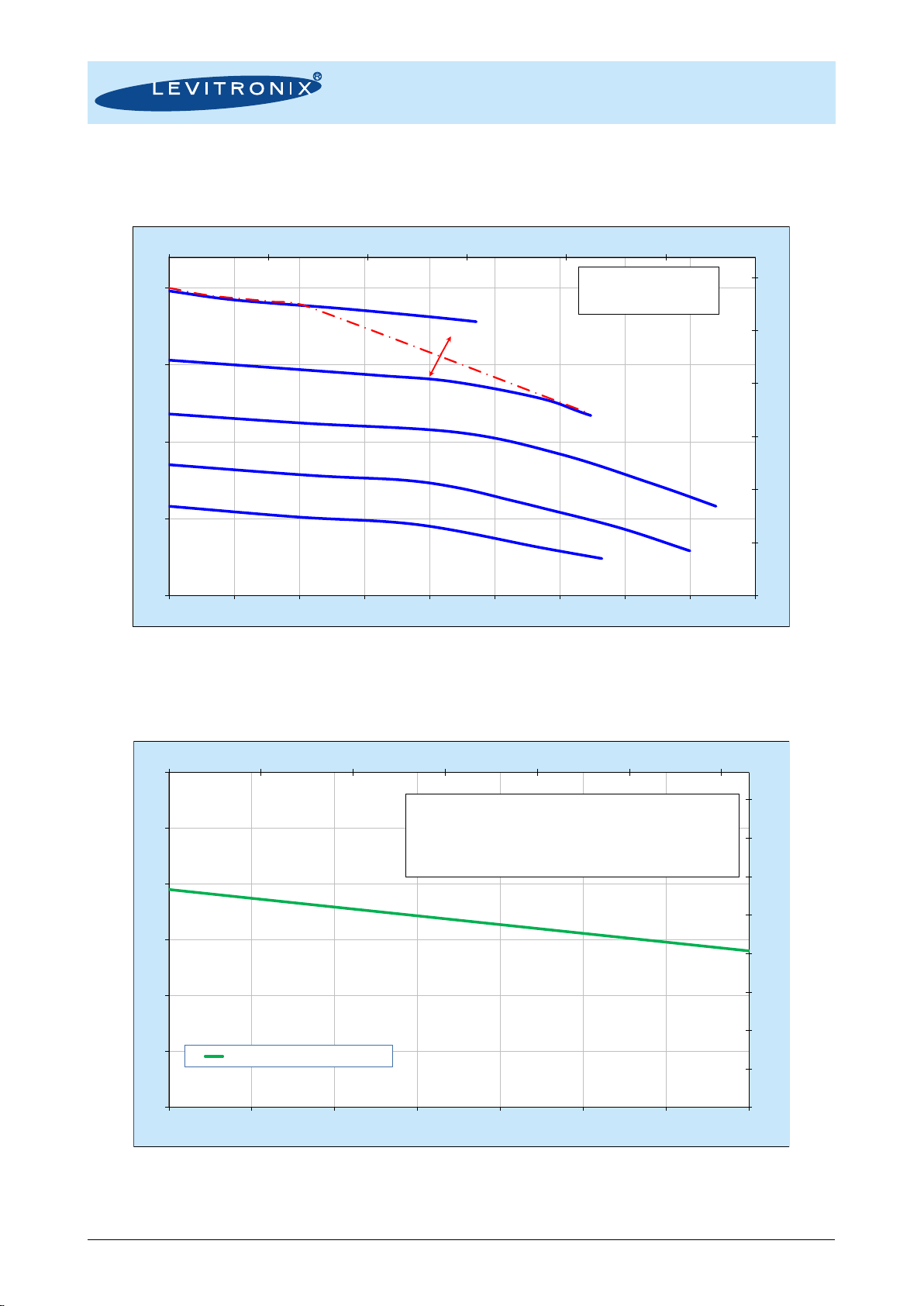

2.4 Pressure-Flow Curves...........................................................................................................................................................8

2.5 Maximum Static Pressure for Pump Heads...........................................................................................................................8

2.6 Basic Dimensions of Main Components................................................................................................................................9

3ENGINEERING INFORMATION...................................................................................................................................................12

3.1 Sealing and Material Concept .............................................................................................................................................12

3.2 Power Supply and Consumption.........................................................................................................................................13

3.3 Temperature Monitoring......................................................................................................................................................13

3.4 Thermal Management.........................................................................................................................................................14

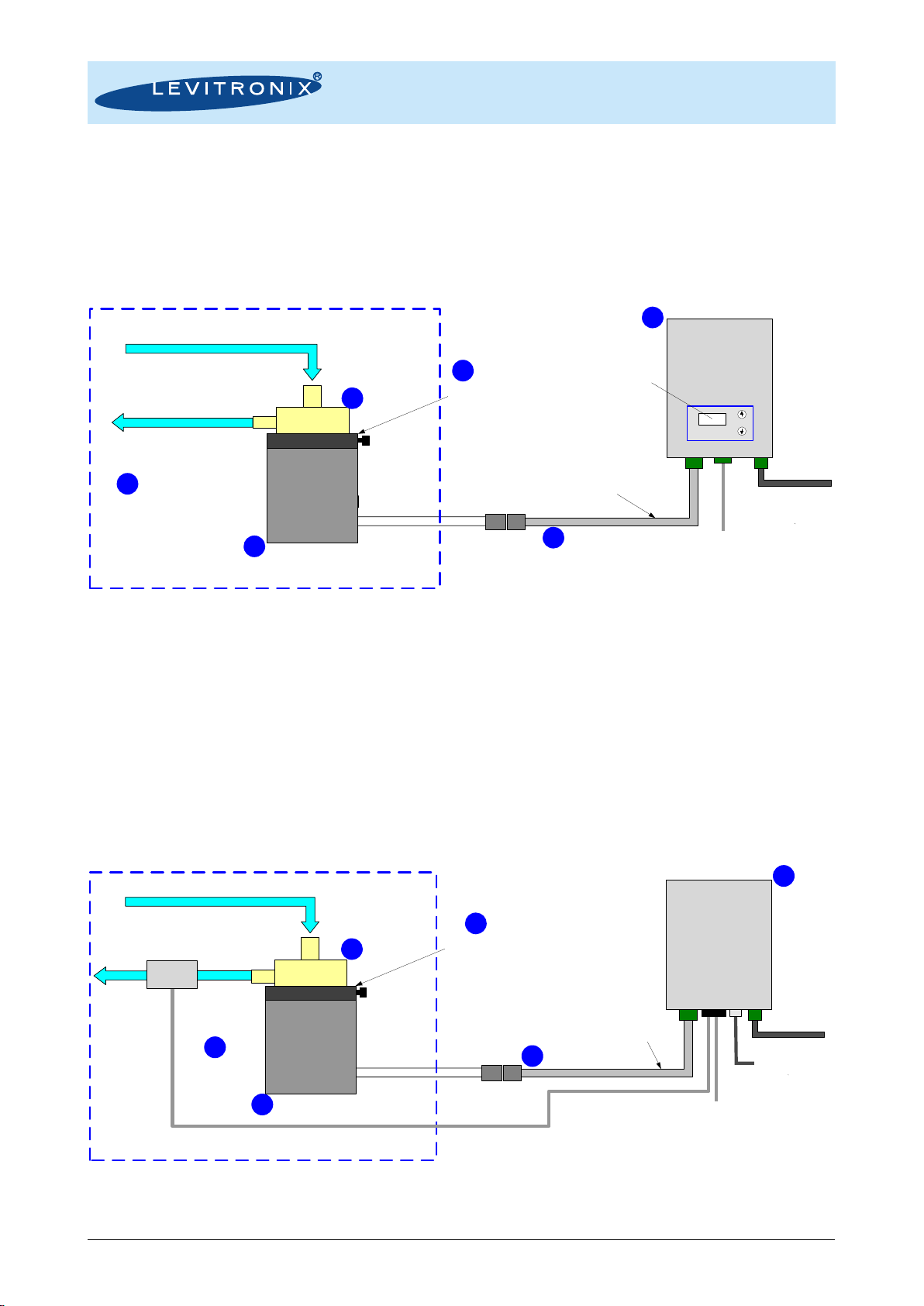

3.1 Hydraulic Circuit Design......................................................................................................................................................17

4INSTALLATION ...........................................................................................................................................................................18

4.1 Electrical Installation of Controller .......................................................................................................................................18

4.2 Mechanical Installation of the Pump/Motor..........................................................................................................................24

4.3 Mechanical Installation of Motors in ATEX Zone 2 Areas ....................................................................................................24

4.4 Mechanical Installation of the Controller..............................................................................................................................24

4.5 Mechanical Installation of Adaptor/Extension Cables ..........................................................................................................25

5OPERATION................................................................................................................................................................................26

5.1 System Operation with LPC-200.1-01 (Stand-Alone Version)..............................................................................................26

5.2 System Operation with Controller LPC-200.2-01 (PLC version)...........................................................................................29

5.3 System Operation for ATEX / IECEx Applications ...............................................................................................................31

6INSTRUCTION FOR USE OF PUMP HEAD.................................................................................................................................32

6.1 Description and Preparation................................................................................................................................................32

6.2 General Warnings and Cautions .........................................................................................................................................32

6.3 Mounting of Pump Head......................................................................................................................................................33

6.4 Removal of Pump Head......................................................................................................................................................33

6.5 Assembly into Circuit...........................................................................................................................................................33

7TROUBLESHOOTING .................................................................................................................................................................34

7.1 Troubleshooting for Operation with Controller LPC-200.1-01...............................................................................................34

7.2 Troubleshooting for Operation with Controller LPC-200.2-01...............................................................................................34

7.3 Troubleshooting with Levitronix®Service Software..............................................................................................................34

8TECHNICAL SUPPORT...............................................................................................................................................................34

9APPENDIX...................................................................................................................................................................................35

9.1 Regulatory Status ...............................................................................................................................................................35

9.2 Symbols and Signal Words.................................................................................................................................................37