PART 2 - OPERATION, MAINTENANCE.

CUSTOM 8000

OPERATION OF VERTICAL HYDRAULIC MODELS

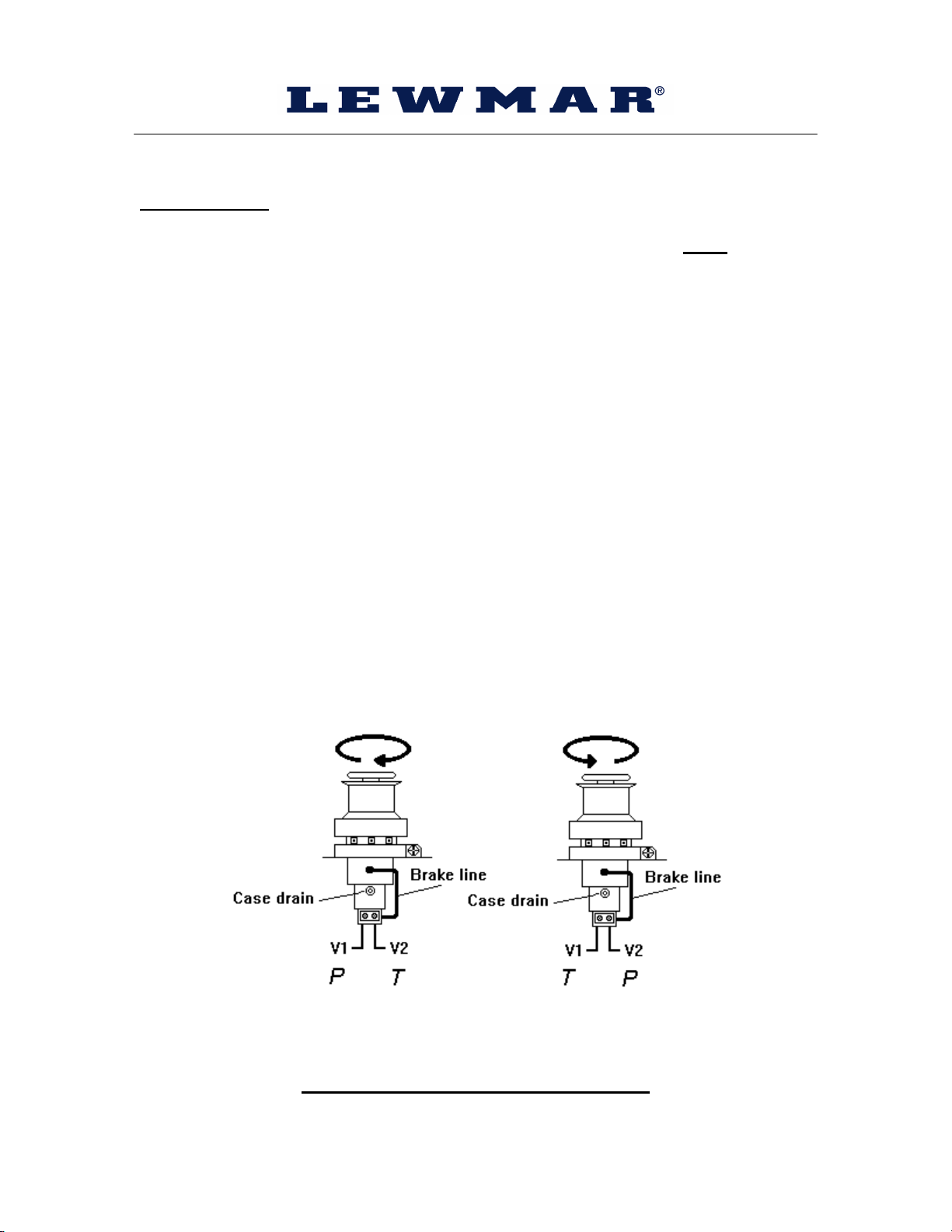

Operation The main shaft, driven by the motor / gearbox, is splined

Explained directly to the capstan. There is a fail-safe integral

brake fitted to the capstan. The brake is released when

hydraulic power is applied to the capstan. The gypsy can

either be powered by the capstan or free running. The

gypsy is powered by engaging the dog drive teeth of

the capstan to those of the gypsy. Engagement and

disengagement of the dog drive is controlled by turning

the top nut, which lifts and lowers the capstan. Spring

loading between the capstan and gypsy facilitates

engagement / disengagement.

The free running gypsy is controlled by tightening or

loosening the full wrap brake band.

Power Up Press the deck switch, remote control or toggle switch

(Anchor Up).

NOTE: Ensure that the brake band is released and that

the dog drive is fully engaged.

Power Down Press the deck switch, remote control or toggle switch

(Anchor Down).

NOTE: Ensure that the brake band is released and that

the dog drive is fully engaged.

Manual Chain Place a Lewmar winch handle in the brake band bi –

Release square and secure the chain gypsy. Place the Lewmar

winch handle into the top nut and raise the capstan until

the dog drive is fully disengaged.

Replace the handle in the brake band bi - square and

carefully release the brake to allow the gypsy to run free.

The descent of the chain can be controlled and stopped

by tightening the band.