LG AVNQ48GM2T1 User manual

Other LG Air Conditioner manuals

LG

LG FLEX MULTI SPLIT User manual

LG

LG MULTI V WATER II ARWN Series User manual

LG

LG W182CM User guide

LG

LG MULTI V S ARUN038GSS4 User manual

LG

LG P12AWN User manual

LG

LG LWM1560BHE User manual

LG

LG UVNH36GLLA1 User manual

LG

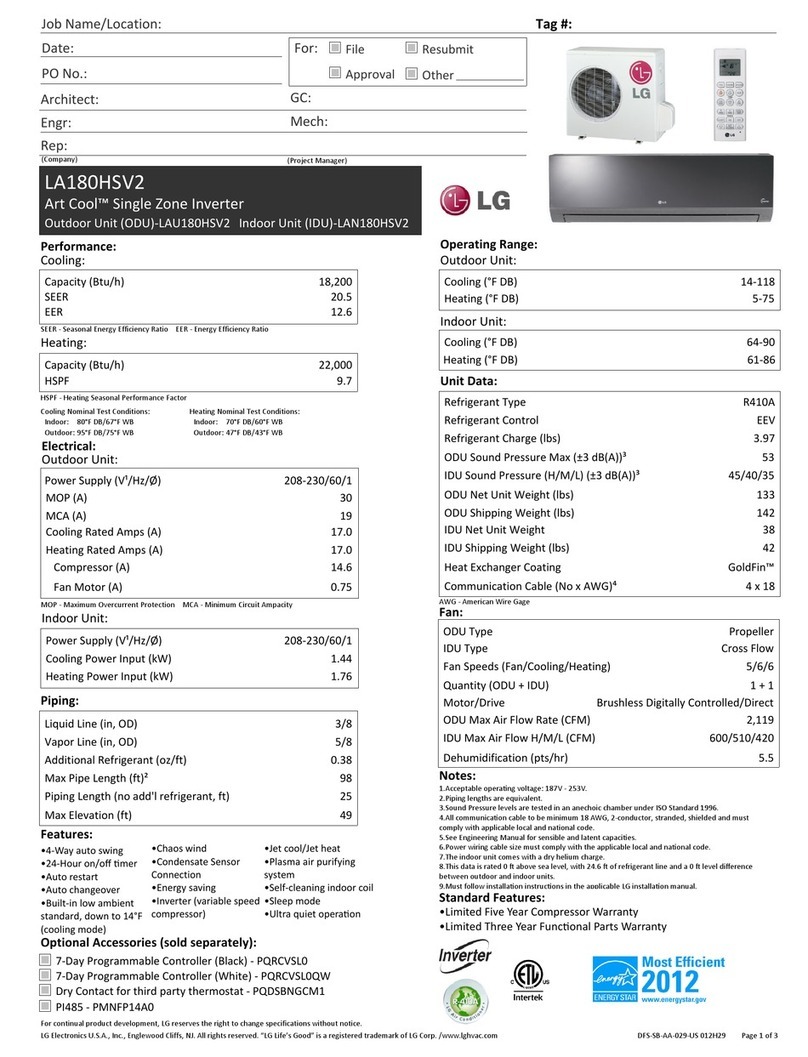

LG LA180HSV2 Installation and user guide

LG

LG MFL40910614 User manual

LG

LG LP090CED User manual

LG

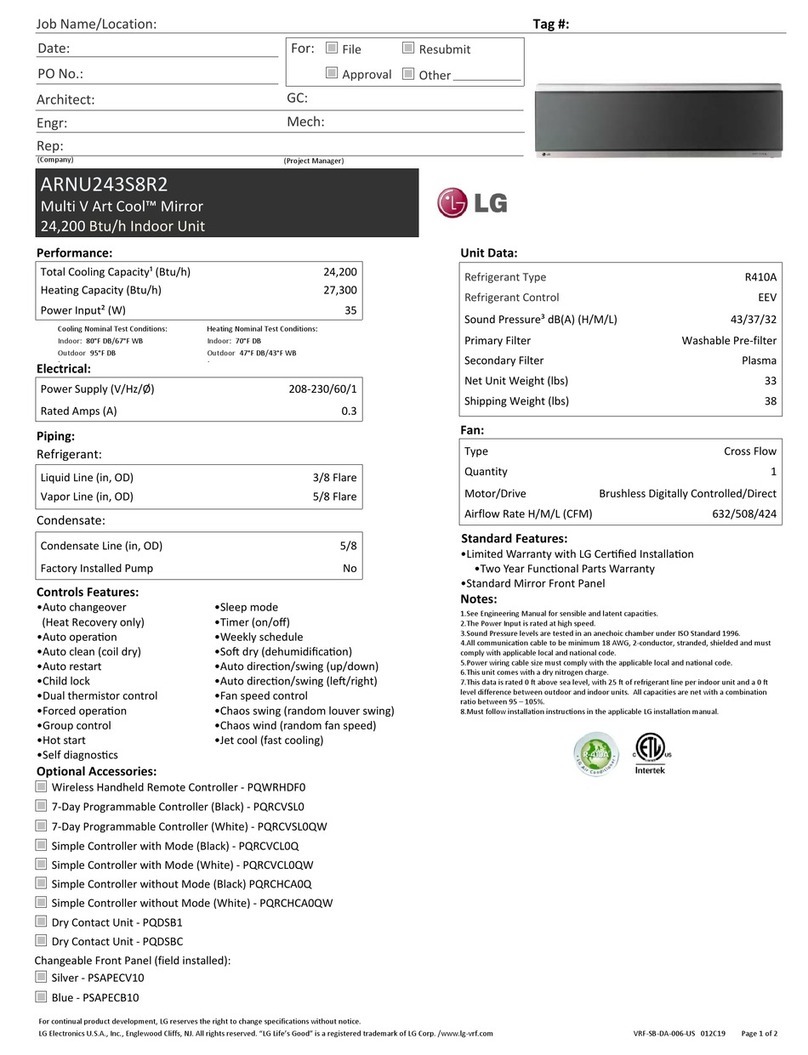

LG ARNU243S8R2 User manual

LG

LG GBUH186HSS0 User manual

LG

LG LZ-H050GBA2 User manual

LG

LG Mega LS240HEV2 User manual

LG

LG LP1423BH User manual

LG

LG LT-H242PLE0 User manual

LG

LG Ceiling Cassette-Type Air Conditioner User manual

LG

LG MFL42262840 User manual

LG

LG Styler S3 F Series User manual

LG

LG Multi Type Air Conditioner User manual

Popular Air Conditioner manuals by other brands

CIAT

CIAT Magister 2 Series Installation, Operation, Commissioning, Maintenance

Bestron

Bestron AAC6000 instruction manual

Frigidaire

Frigidaire FFRE0533S1E0 Use & care guide

Samsung

Samsung AS09HM3N user manual

Frigidaire

Frigidaire CRA073PU11 use & care

Soleus Air

Soleus Air GB-PAC-08E4 operating instructions