- 6 -

Copyright ©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes LGE Internal Use Only

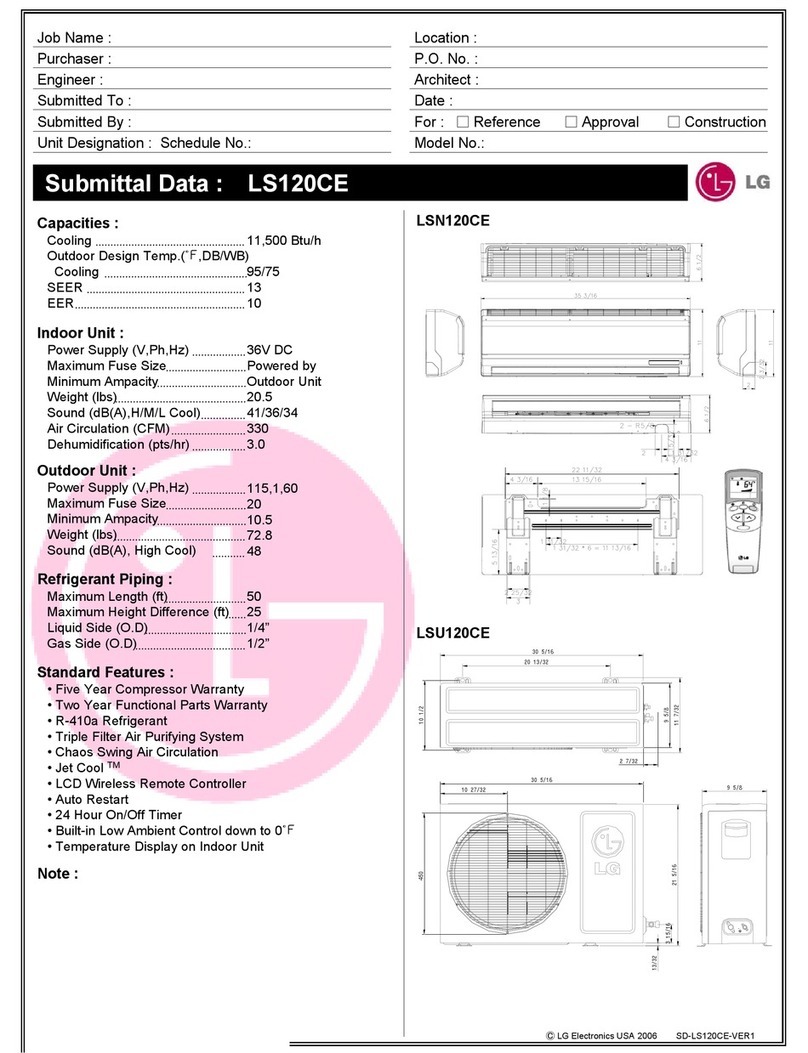

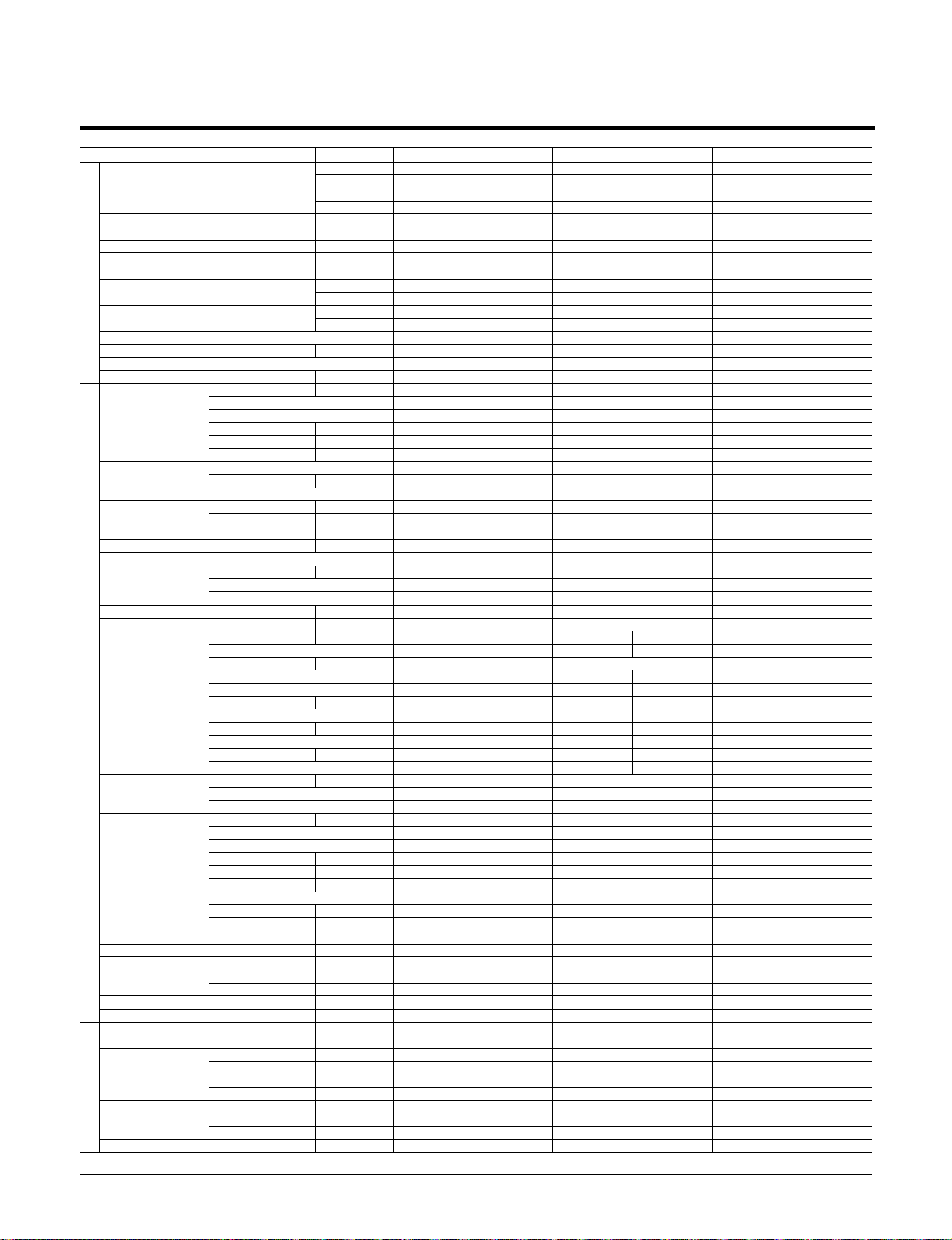

Items Unit

Cooling Capacity kcal/hr(W)

Btu/hr

Heating Capacity kcal/hr(W)

Btu/hr

Input Cooling/Heating W

Running Current Cooling/Heating A

Starting Current Cooling/Heating A

Power Supply Ø,V,Hz

Power Factor %

E.E.R Cooling kcal/hr W(W/W)

Btu/hr W

C.O.P Heating W/W(kcal/hr W)

Btu/hr W

Setting temperature range(cool/heat)

Dehumidification Rate l/h

Refrigerant Control

Refrigerant charge g(oz), type

Indoor fan motor Output w

Model

No. of Poles

Input W

Running Current A

Capacitor µF/Vac

Indoor Fan Type

No. Used / Diameter EA/inch(mm)

Motor Step

Indoor Fan RPM Cooling(H/M/L) rpm

Heating(H/M/L) rpm

Air Circulation Indoor (H/M/L) CMM(CFM)

Noise Level(Sound Press,1m)

Indoor(H/M/L) dB(A)±3

Temperature Controller

Indoor Coil Tube Size (OD) inch(mm)

Fins per inch

No. of Rows & Column

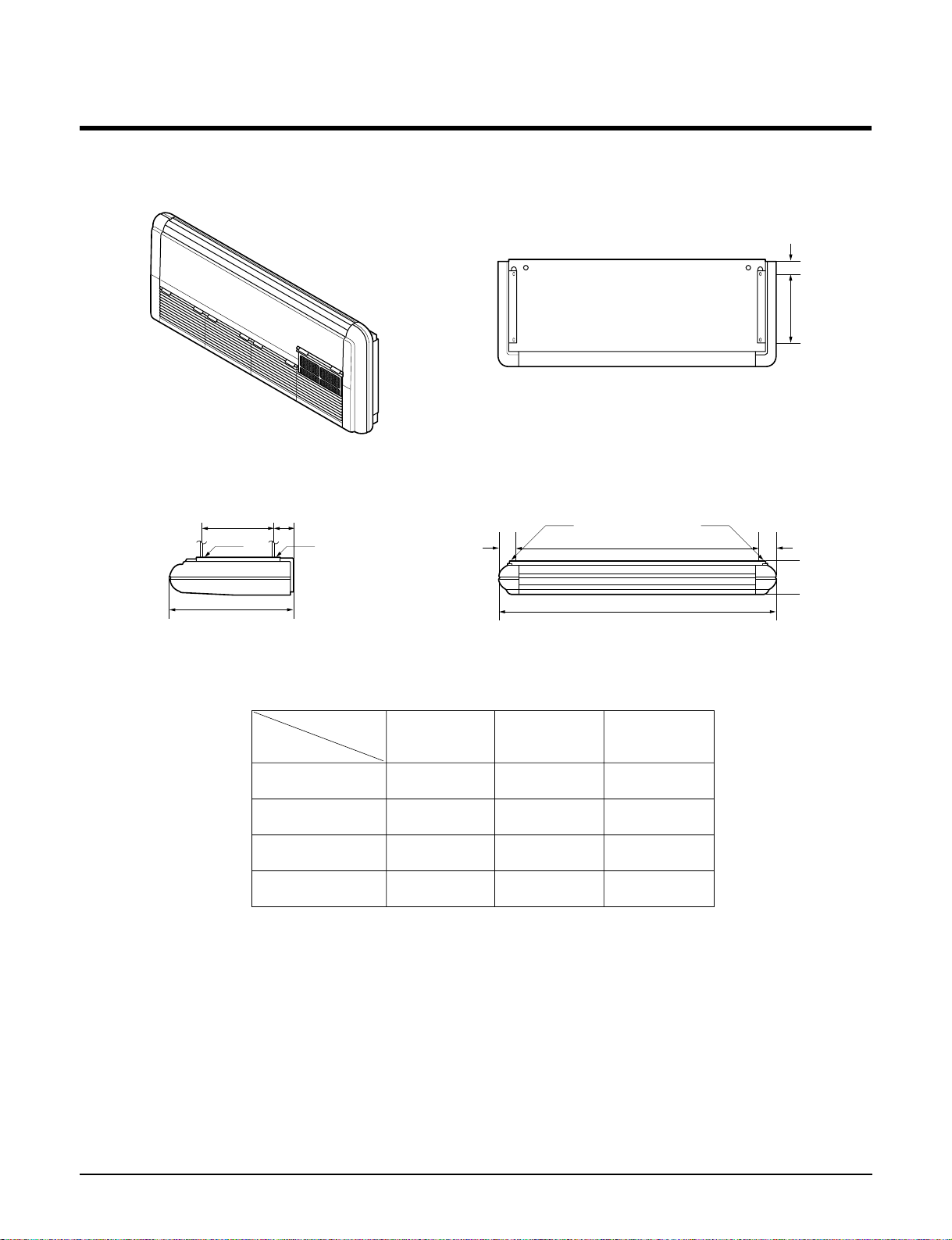

Dimensions (W*H*D) Indoor inch(mm)

Net Weight indoor kg(lbs)

Compressor Locked Rotor Amp. A

Type

Quantity No

Model

Maker

Capacity Btu/hr

Motor Type

Motor Input W

Oil Type

Oil Charge cc

O.L.P Type(model name)

Outdoor Coil Tube Size (OD) inch(mm)

Fins per inch

No. of Rows & Column

Outdoor fan motor Output W

Model

No. of Poles

Input W

Running Current A

Capacitor µF/Vac

Outdoor Fan Type

No. Used / Diameter EA/mm

Discharge Side/Top

Speed rpm

Air Circulation Outdoor CMM(CFM)

Noise Level(Sound Press,1m)

Outdoor dB(A)±3

SVC Valve Liquid inch(mm)

Gas inch(mm)

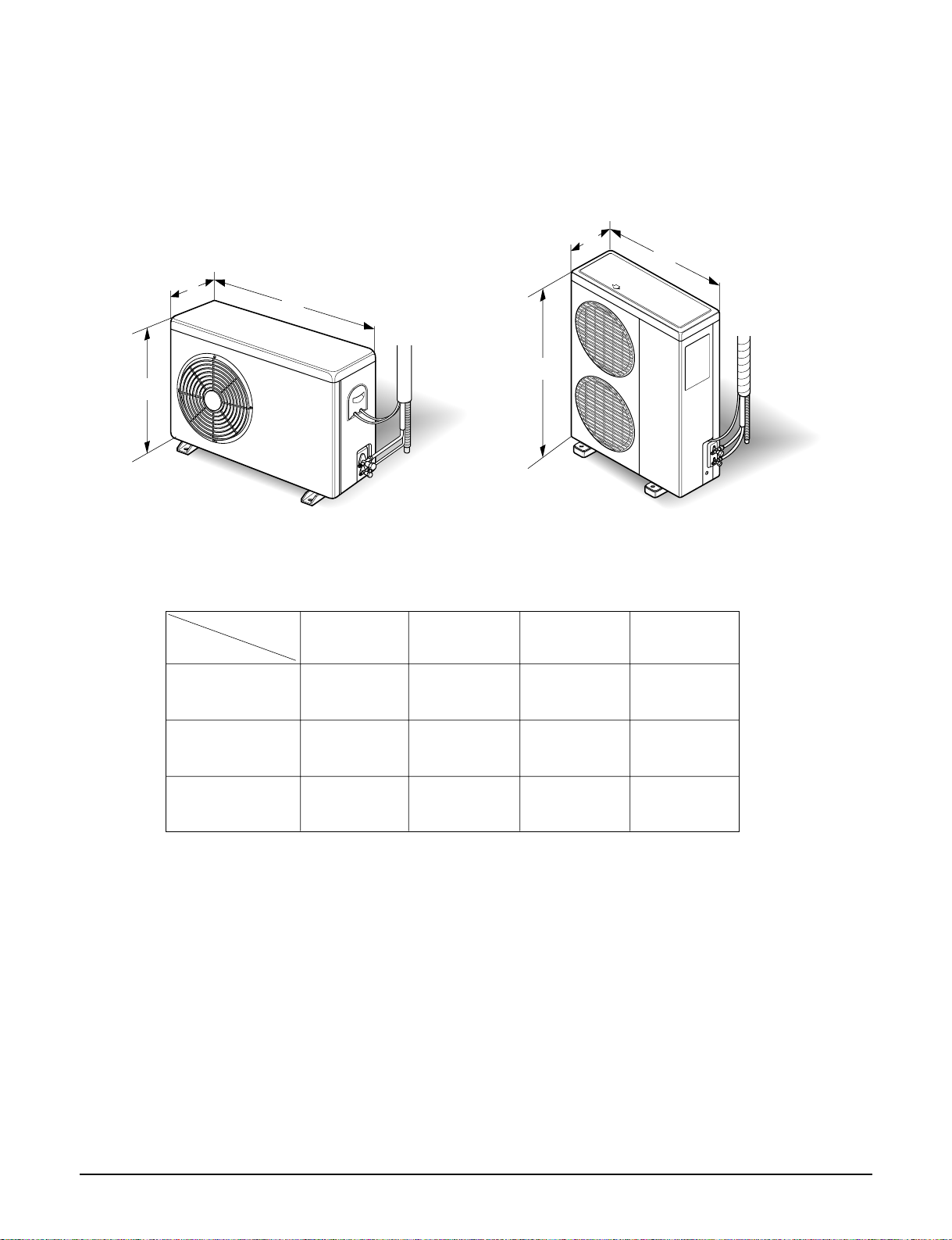

Dimensions (W*H*D) Outdoor inch(mm)

Net Weight Outdoor kg(lbs)

Power Supply Cable No.* mm2

Connecting Cable No.* mm2

Connecting Tube Liquid Side inch(mm)

(Ø. Socket Flare) Gas Side inch(mm)

Length, std m

Max length/elevation m

Drain hose(Inner Ø)

Indoor Unit/Outdoor Unit

mm

Packing Dimension Indoor(W*H*D) inch(mm)

Outdoor(W*H*D) inch(mm)

Stuffing Quantity With(Without) S/Parts 20/40ft

LV-C602HLA0 LV-C48BGLA0 LV-C60BHLA0

15,120/(17,584) 12,096(14,067) 15,120(17,584)

60,000 48,000 60,000

---

---

6,300 5,200 6,300

29 14.5 18.2

101 90 124

1, 220, 60 3, 220, 60 3, 220, 60

98.8 92.6 89.3

2.33(2.72) 2.22(2.57) 2.14(2.48)

9.25 8.8 8.5

---

---

18~30/- 18~30/- 18~30/-

7.67 5.2 7.1

Capillary Tube Capillary Tube Capillary Tube

4,050(145.4),R22 3,800(134),R22 4,680(165),R22

KHF2G4002 KHF2G4001 KHF2G4002

444

450 380 450

2.1 1.73 2.1

10.0/370 7.5/370 10.0/370

Centrifugal Centrifugal Centrifugal

4/164 3/164 4/164

333

1,450/1,150/1,000 1,470/1,240/1,040 1,450/1,150/1,000

---

37/31/27 36/32/27 37/31/27

61/59/57 59/57/55 61/59/57

Thermistor Thermistor Thermistor

9.7 9.7 9.7

13 13 13

4R 12C 4R 10C 4R 12C

1,550/650/292 1,550/650/272 1,550/650/292

63(137) 61(134) 63(137)

142 92 124

Reciprocating Reciprocating Scroll

111

CRN5-0500-PFV AVB5549EXT SR061RAA

Copeland TECUMSEH LG

62,700 48,096 62,000

Condenser Inducted PSC Three Phase Induction Motor

6,270 4,610 5,535

SUNISO 4GDID WITCO LP200T SUNISO 4GSI

1,774 2,000 1,800

Internal Internal Internal

0.375(9.52) 0.375(9.52) 0.375(9.52)

16 17 16

2R22C 2R 44C 2R 44C

90*2 90*2 90*2

AMR071B9 AMR071B9 AMR071B9

666

168*2 168*2 168*2

0.81*2 0.81*2 0.81*2

6.0/370 6.0/370 6.0/370

Propeller Propeller Propeller

2/382 2/382 2/382

Side Discharge Side Discharge Side Discharge

900 900 900

49(1,730)*2 49(1,730)*2 49(1,730)*2

62 62 62

1/2(12.7) 1 / 2 (12.7) 1 / 2 (12.7)

3/4(19.05) 3 / 4 (19.05) 3 / 4 (19.05)

35.43*48.23*14.57(900*1225*370) 35.43*48.23*14.57(900*1225*370) 35.43*48.23*14.57(900*1225*370)

95(209) 95(209) 95(209)

3*8.5 3*8.5 3*8.5

4*0.75 4*0.75 4*0.75

1/2(12.7) 1/2(12.7) 1/2(12.7)

3/4(19.05) 3/4(19.05) 3/4(19.05)

7.5 7.5 7.5

15/12.5 15/12.5 15/12.5

22.22/ 22.22 22.22/

1635/751/378 1635/751/358 1635/751/378

42.1*52.1*19.5(1070*1300*495) 42.1*52.1*19.5(1070*1300*495) 42.1*52.1*19.5(1070*1300*495)

21/44 21/45 21/44

General

Indoor

Outdoor

Outdoor