–9–

Operation Details

(1) The function of main control

1. Time Delay safety Control

• 3min¡ƒ The compressor is ceased for 3minutes to balance the pressure in the refrigeration cycle.

(Protection of compressor)

• 30sec¡ƒThe 4-way valve is ceased for 30sec. to prevent the refrigerant-gas abnormal noise when the Heating

operation is OFF or switched to the other operation mode while compress is off.

While compressor is running, it takes 3~5 seconds to switch.

2. Soft-Dry Operation

• The indoor fan speed is automatically set to the low, so the shift of the indoor fan speed is impossible because of

already being set to the best speed for Dry Operation by Micom Control.

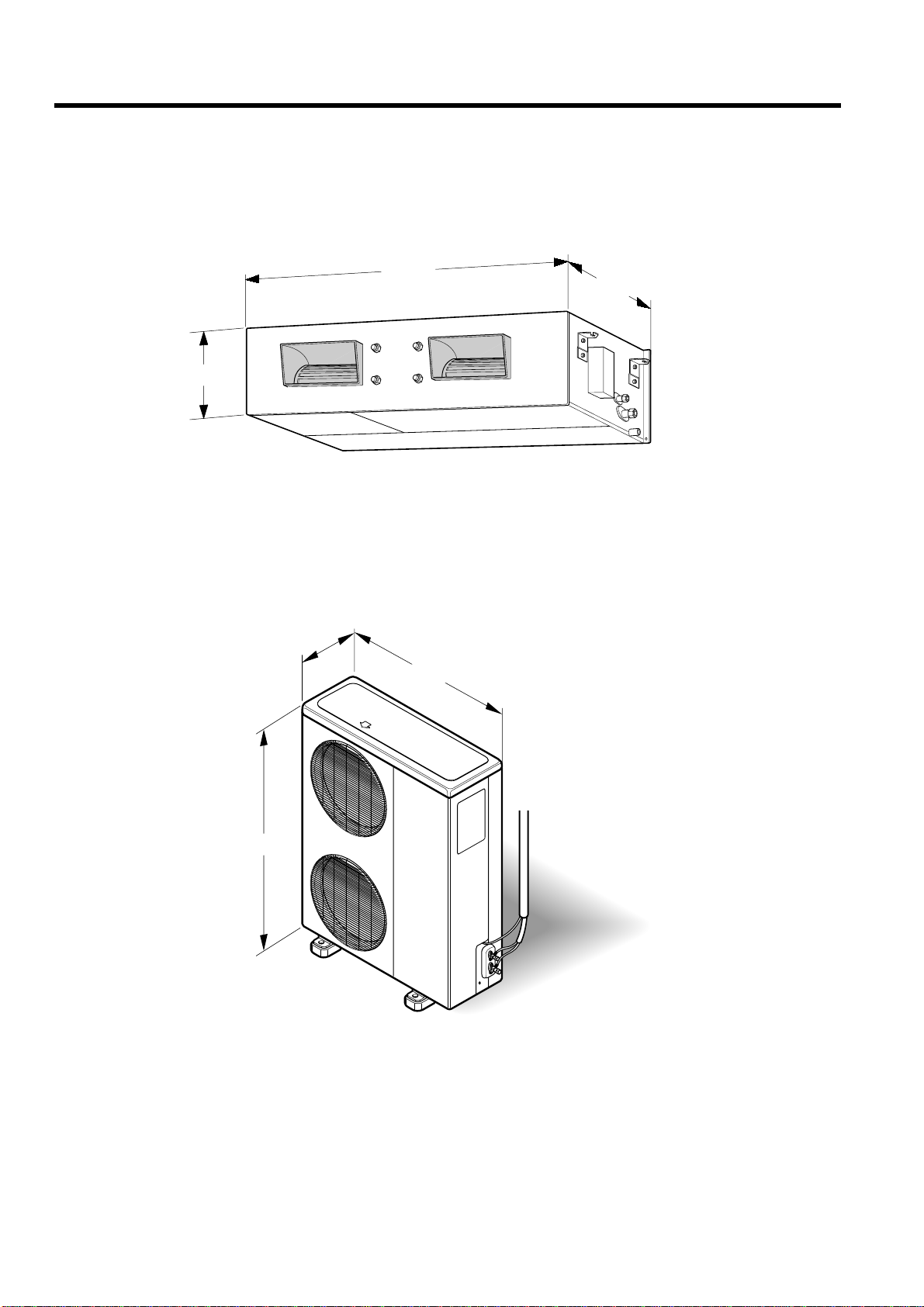

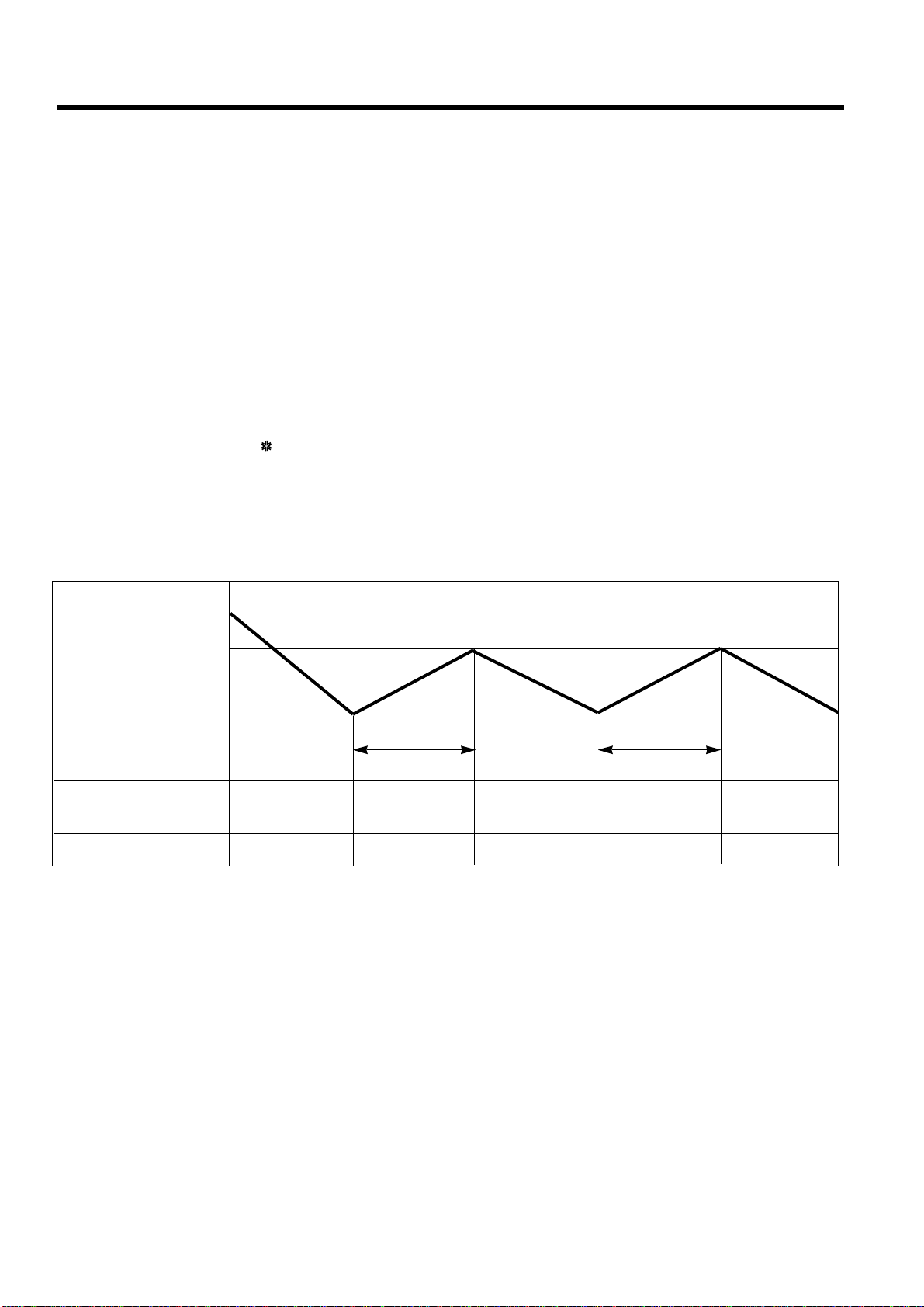

3. Cooling Mode Operation

• When selecting the Cooling( ) Mode Operation, the unit will operate according to the setting by the remote con-

troller and the operation diagram is as following

Intake Air temp.

COMP. ON

(SET TEMP.+0.5°C)

COMP. OFF

(SET TEMP. -0.5°C) More than More than

3 minutes 3 minutes

Selecting Selecting Selecting

fan speed fan speed fan speed

COMPRESSOR ON OFF ON OFF ON

INDOOR FAN Low Low