LGETH -180704-054 / Rev. 0LG Electronics

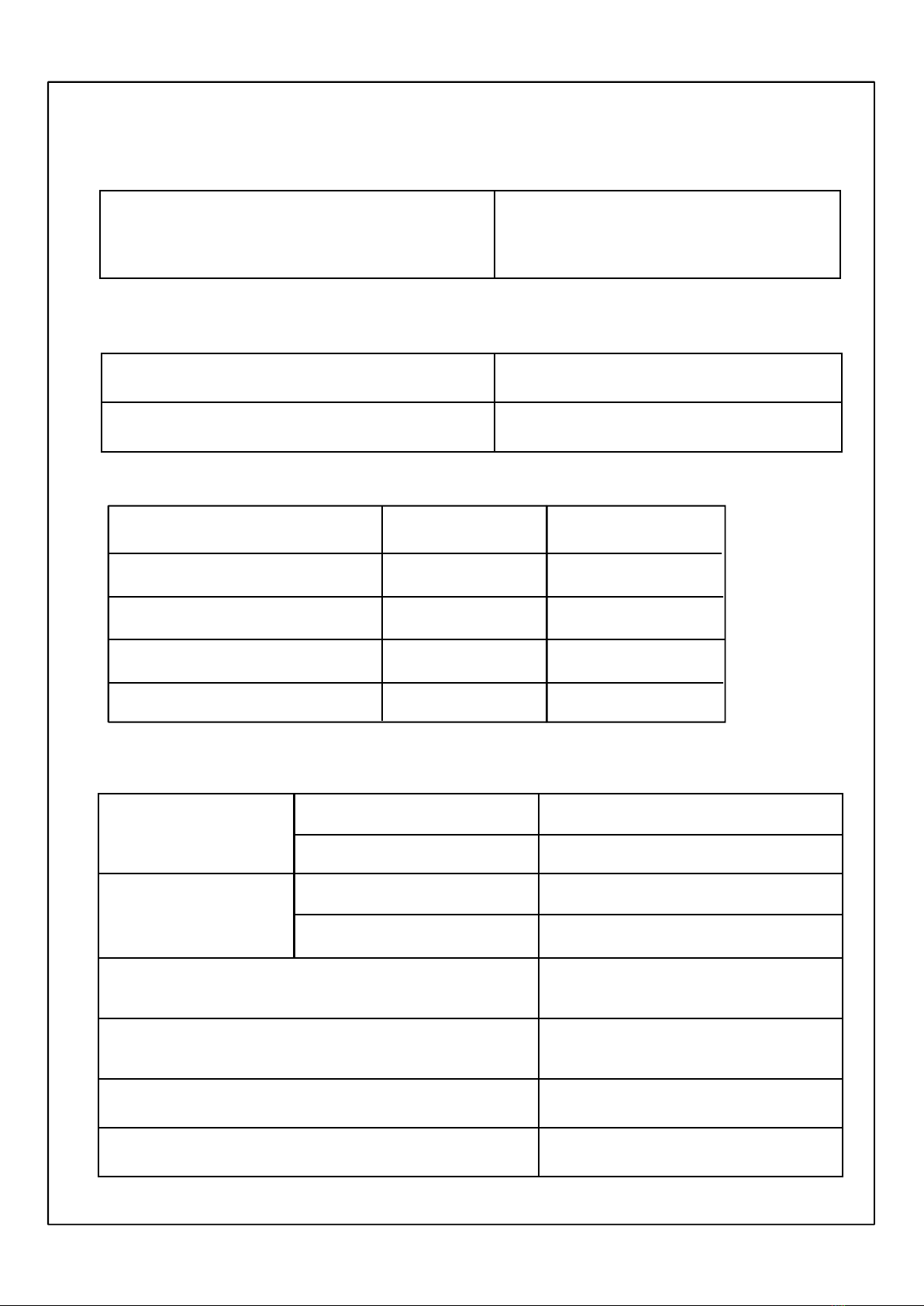

Refrigerant Charge Limit Max 2,500g

(Charge limit depends on Oil Dilution Rate**note 2 & accumulator ‘K’)

Liquid Refrigerant Back

System should be designed not to allow the liquid to go back to

compressor which cause knocking noise , current increase or

undesirable vibration and make short compressor life time.

Δ T : Temp. Difference Δ T = Case Bottom Temp.- Condensing Temp.

It must be kept Δ T ≥ 5℃

Pressure Difference

in Operating

The Pressure difference in operating shall be 5.0㎏f/㎠ or more,

but 3 minutes starting excluded.

ON/OFF Operation Each cycle should be at least 6 minutes

(ON Time : at least 3 minute , OFF Time : at least 3 minutes)

3.2 Application Limit

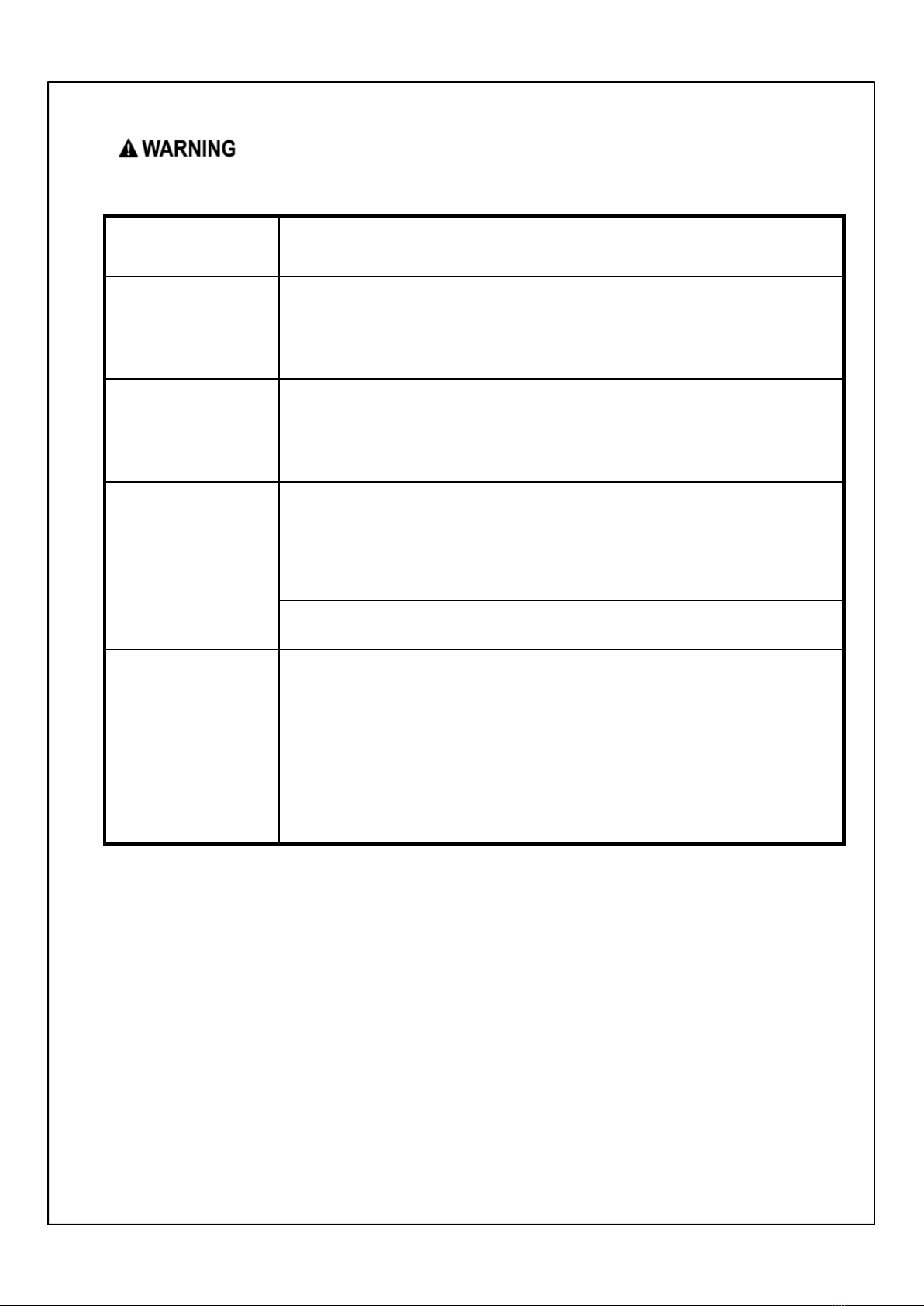

※This guide contains many important safety messages. Always read and obey all safety messages.

You can be killed or seriously injured if you don’t follow instructions.

Page 9 / 24GVH2 2PAB

(ON Time : at least 3 minute , OFF Time : at least 3 minutes)

Pressure Difference

at Starting

When starting, discharge pressure is balanced with suction pressure.

( Pd – Ps ≤ 0.5 ㎏f/㎠ )

Tilt in Operation The allowable tilt of the compressor in operation shall be 5˚ or less.

System Accumulator

The Accumulator volume should be enough to cover 50% of

maximum system refrigerant volume.

Ratio coefficient ‘K’ should be over 0.6(heating system) or 0.4(cooling

system)

Effective Volume of Accum. × Specific gravity of Refrigerant

K = --------------------------------------------------------------------------

Charged Weight of Refrigerant

※ Effective Volume of Accumulator = 580 ㎤

※ Specific Gravity of Refrigerant (R410A) = 1.085 g/㎤ ( at 20℃ )

If coefficient “K” does not meet recommendation, refrigerant system

must check liquid back phenomenon at accumulator.

Protecting Reverse

Operation

The compressor must be operated by proper voltage in accordance

with the frequency without reverse revolution condition. The reverse

revolution condition can be avoided by just keeping right order of

phase supplied power source.