5Safety 5

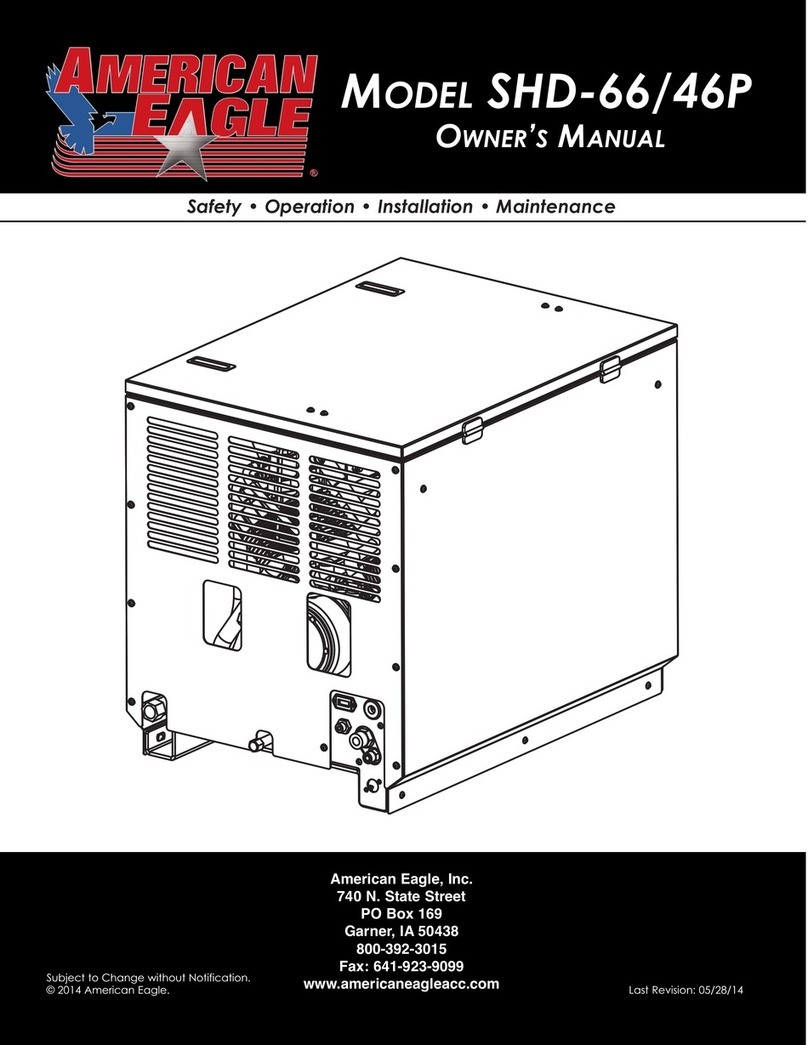

The SHD-66DD Hydraulic Air Compressor will

provide safe and dependable service if operated

according to instructions. Read and understand

the safety precautions given in this manual and

on the decals attached to the shields. Failure to

do so can result in personal injury or equipment

damage.

Operators and maintenance personnel must

always comply with the safety precautions.

These precautions are given here for your

safety. Review them carefully before operating

the compressor and before performing

maintenance or repairs.

Supervising personnel should develop additional

precautions relating to the specific work area

and local safety regulations.

Precautions

Always wear safety equipment such as goggles,

ear plugs and head protection at all times when

operating the compressor.

Do not inspect or clean the compressor while

the hydraulic power source is connected.

Accidental engagement of the tool can cause

serious injury.

Before performing any maintenance on the

compressor, place a warning tag on the

hydraulic power source or disconnect the hoses

from the compressor motor to prevent

accidental startup of the compressor.

Always connect hoses to the compressor before

energizing the hydraulic power source. Be sure

all hose connections are tight, both air and

hydraulic.

Establish a training program for all operators to

ensure safe operation.

Do not operate the compressor unless

thoroughly trained or under the supervision of

an instructor.

Do not operate the compressor if it is damaged,

improperly adjusted or not completely or

properly assembled.

ever operate the compressor with any of the

guards removed.

Do not attempt to adjust or disable the

compressors air pressure relief valve. This

valve limits the air pressure to 175 PSI.

The surface of the air compressor and the

plumbing between the compressor and the

cooler may reach temperatures above 150

degrees. Touching these surfaces during

operation can cause burns.

The air taken in by the air compressor must be

free of flammable fumes and vapors.

Compressor speed should not exceed 1000

RPM.

Use and operate this air compressor only in full

compliance with all pertinent O.S.H.A.

requirements and all Federal, State and Local

codes or requirements.

This manual contains vital information for the safe use and efficient

operation of this unit. Carefully read the operators manual before

starting the unit. Failure to adhere to the instructions could result in

serious bodily injury or property damage.

Chapter 1: Safety