5. Manual Adjustment

5.1. ADC Adjustment

5.1.1. Overview

ADC adjustment is needed to find the optimum black level and

gain in Analog-to-Digital device and to compensate RGB

deviation.

5.1.2. Equipment & Condition

(1) Adjustment remote coontrol

(2) 801GF(802B, 802F, 802R) or MSPG925FA Pattern Generator

- Resolution :

480i, Comp1 (MSPG-925FA: Model-209, Pattern-65)

1080p Comp1 (MSPG-925FA: Model: 225, Pattern-65)’

1080p RGB (MSPG-925FA: Model-225, Pattern-65)

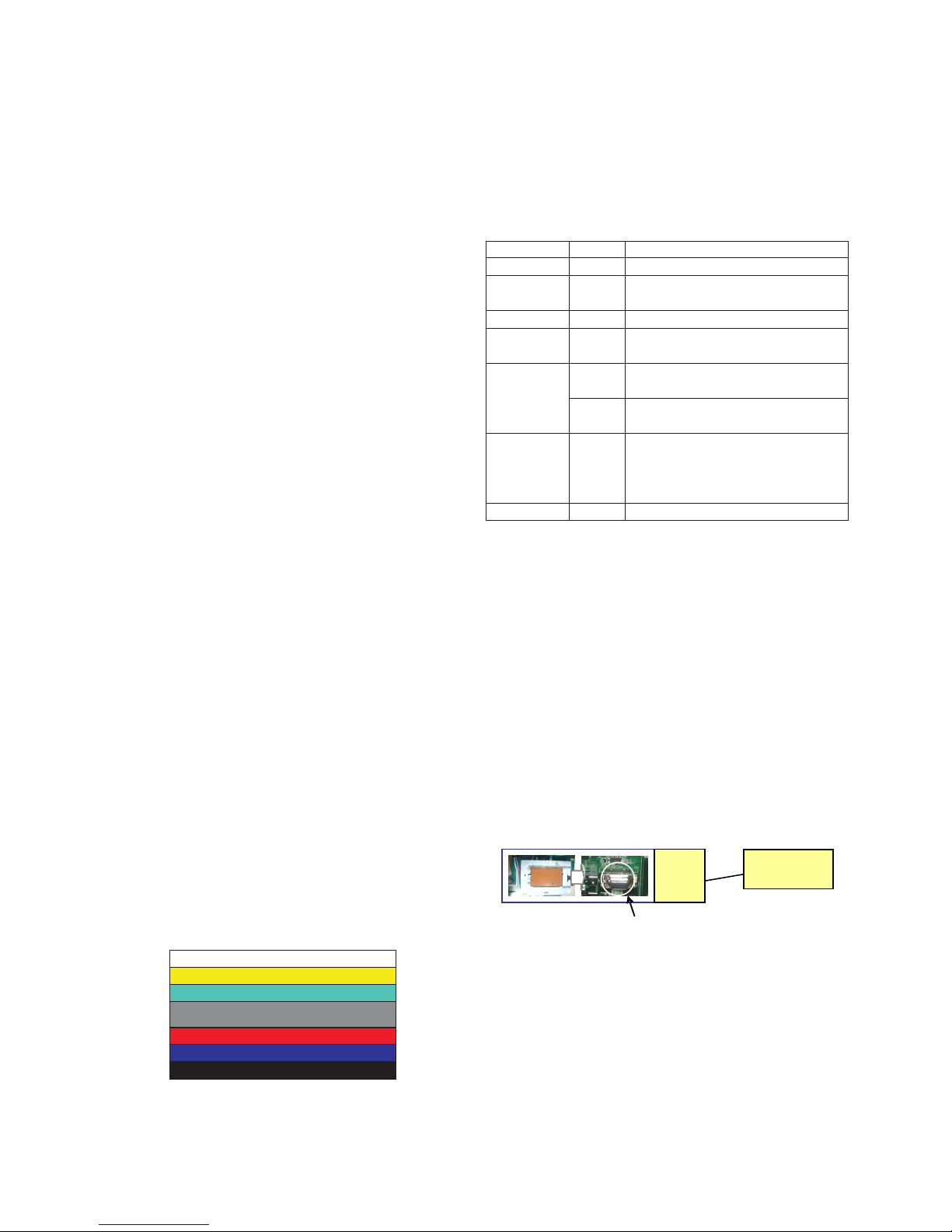

- Pattern : Horizontal 100% Color Bar Pattern

- Pattern level: 0.7 ± 0.1 Vp-p

- Image

(3) Must use standard cable

5.1.3. Adjust method

(1) ADC 480i/1080p Comp1, RGB

1) Check connected condition of Comp1 cable to the

equipment.

2) Give a 480i, Horizontal 100% Color Bar Pattern to

Comp1.(MSPG-925FA -> Model: 209, Pattern: 65)

3) Change input mode as Component1 and picture mode

as “Standard”.

4) Press the In-start Key on the ADJ remote control after at

least 1 min of signal reception. Then, select ‘7. External

ADC’. And press OK or Right key for going to sub menu.

5) Press OK in Comp 480i menu.

6) Give a 1080p Mode, Horizontal 100% Color Bar Pattern

to Comp1. (MSPG-925A -> Model: 225, Pattern: 65)

7) Press OK in Comp 1080p menu.

8) Press OK in RGB menu.

9) If ADC Comp is successful, “ADC Component Success”

is displayed.

If ADC calibration is failure, “ADC Component Fail” is

displayed.

10) If ADC calibration is failure, after recheck ADC pattern

or condition, retry calibration

11) If ADC RGB is successful, “ADC RGB Success” is

displayed. If ADC calibration is failure, “ADC RGB Fail”

is displayed.

12) If ADC calibration is failure, after recheck ADC pattern

or condition, retry calibration Error message refer to 5).

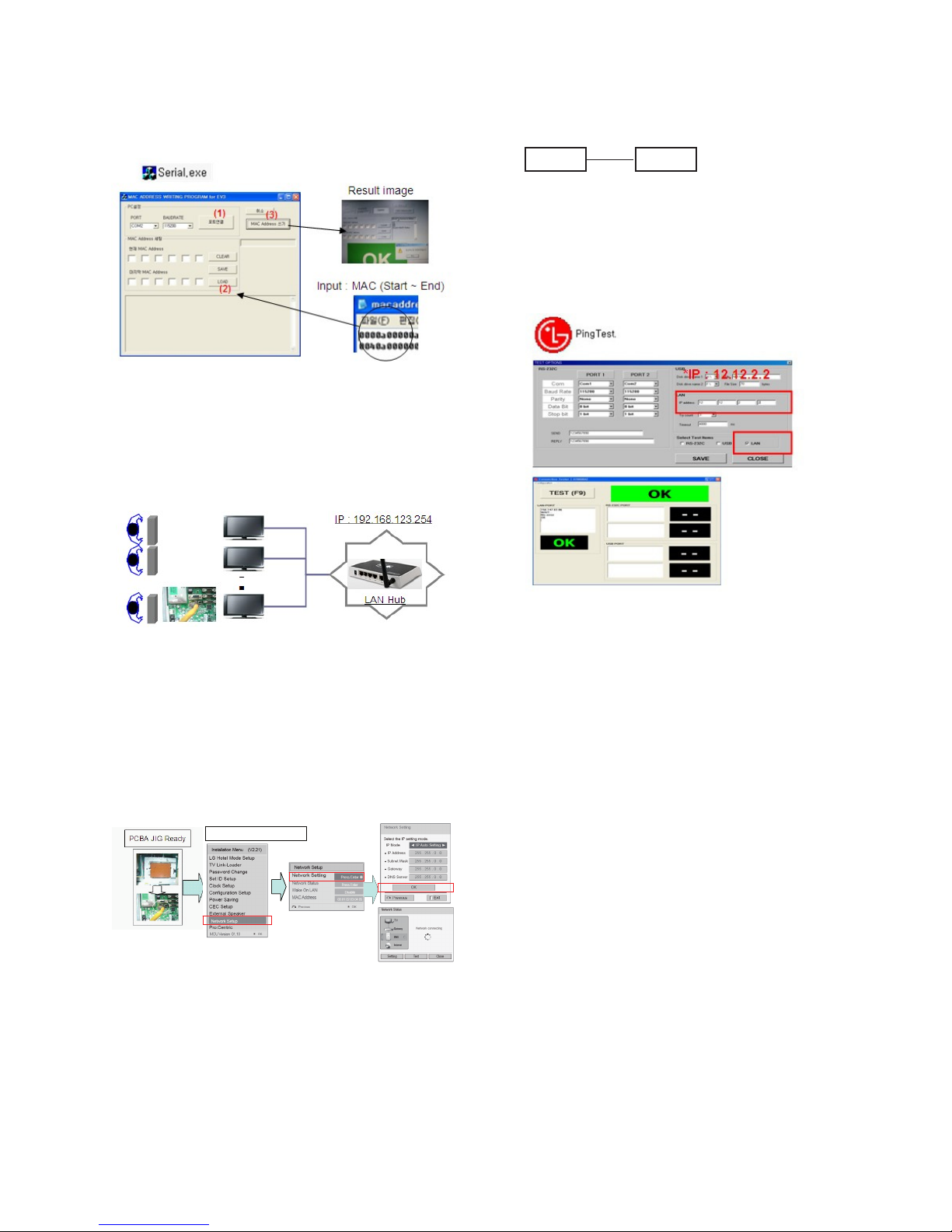

5.2. EDID(The Extended Display Identification

Data)/DDC(Display Data Channel) download

(1) Overview

It is a VESA regulation. A PC or a MNT will display an

optimal resolution through information sharing without any

necessity of user input. It is a realization of “Plug and Play”.

(2) Equipment

- Since embedded EDID data is used, EDID download JIG,

HDMI cable and D-sub cable are not need.

- Adjustment remote control

(3) Download method

1) Press ADJ key on the Adjustment remote control

2) Select EDID D/L menu.

3) By pressing Enter key, EDID download will begin.

4) If Download is successful, OK is display, but If

Download is failure, NG is displayed.

5) If Download is failure, Re-try download.

<Caution>

When EDID Download, must remove RGB/HDMI Cable.

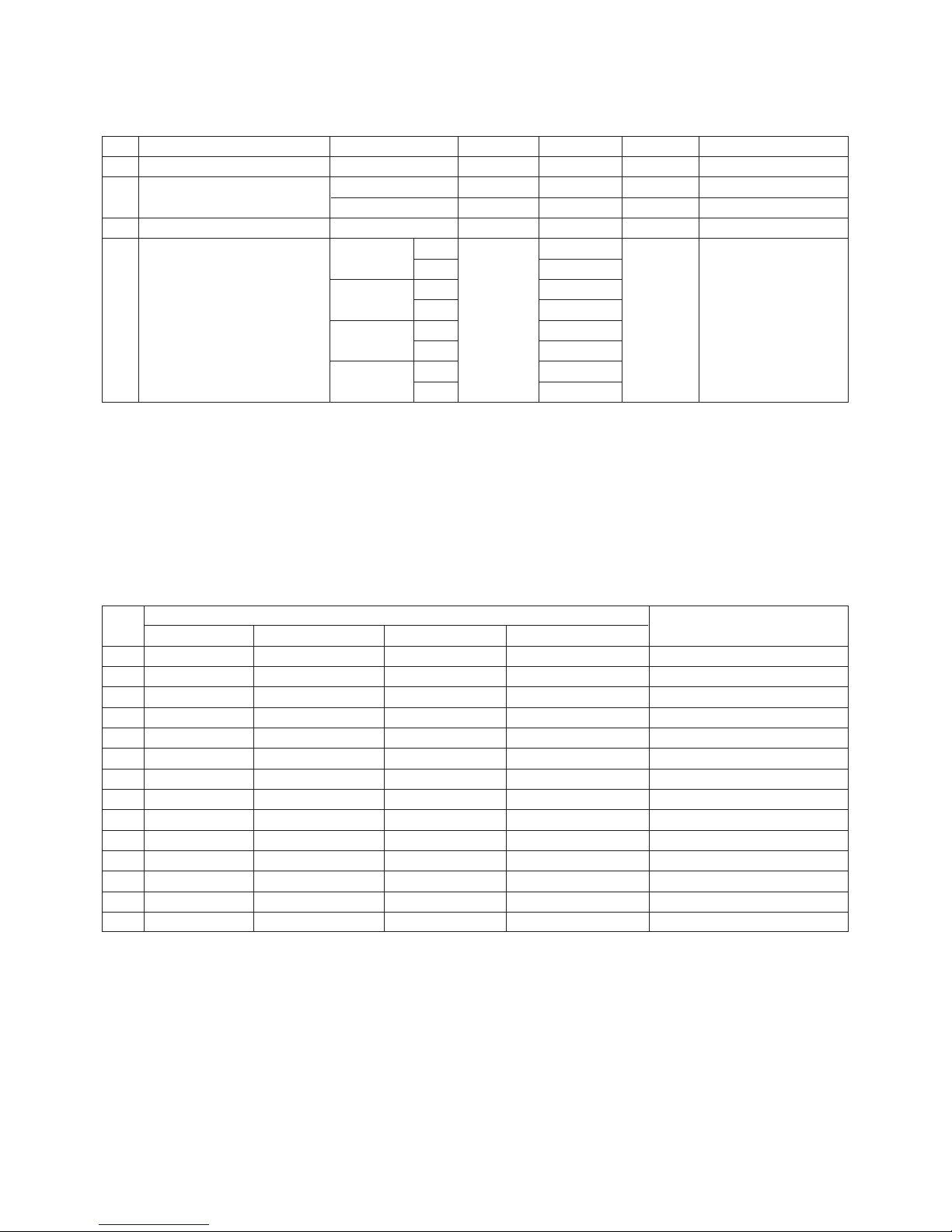

(4) EDID DATA

AHDMI

ARGB

- 10 - LGE Internal Use OnlyCopyright © 2011 LG Electronics. Inc. All rights reserved.

Only for training and service purposes

D-sub to D-sub DVI-D to HDMI or HDMI to HDMI

For HDMI EDIDFor Analog EDID

0x00 0x01 0x02 0x03 0x04 0x05 0x06 0x07 0x08 0x09 0x0A 0x0B 0x0C 0x0D 0x0E 0x0F

0x00 00 FF FF FF FF FF FF 00 1E 6D ⓐⓑ

0x01 ⓒ01 03 80 10 09 78 0A EE 91 A3 54 4C 99 26

0x02 0F 50 54 A1 08 00 71 4F 81 80 01 01 01 01 01 01

0x03 01 01 01 01 01 01 02 3A 80 18 71 38 2D 40 58 2C

0x04 45 00 A0 5A 00 00 00 1E 01 1D 00 72 51 D0 1E 20

0x05 6E 28 55 00 A0 5A 00 00 00 1E 00 00 00 FD 00 3A

0x06 3E 1E 53 10 00 0A 20 20 20 20 20 20 ⓓ

0x07 ⓓ01 ⓔ

0x00 02 03 26 F1 4E 10 1F 84 13 05 14 03 02 12 20 21

0x01 22 15 01 26 15 07 50 09 57 07 67 ⓕ

0x02 ⓕE3 05 03 01 01 1D 80 18 71 1C 16 20 58 2C

0x03 25 00 A0 5A 00 00 00 9E 01 1D 00 80 51 D0 1A 20

0x04 6E 88 55 00 A0 5A 00 00 00 1A 02 3A 80 18 71 38

0x05 2D 40 58 2C 45 00 A0 5A 00 00 00 1E 66 21 50 B0

0x06 51 00 1B 30 40 70 36 00 A0 5A 00 00 00 1E 00 00

0x07 00 00 00 00 00 00 00 00 00 00 00 00 00 00 01 ⓔ2

0x00 0x01 0x02 0x03 0x04 0x05 0x06 0x07 0x08 0x09 0x0A 0x0B 0x0C 0x0D 0x0E 0x0F

0x00 00 FF FF FF FF FF FF 00 1E 6D ⓐⓑ

0x01 ⓒ01 03 68 10 09 78 0A EE 91 A3 54 4C 99 26

0x02 0F 50 54 A1 08 00 81 80 61 40 45 40 31 40 01 01

0x03 01 01 01 01 01 01 02 3A 80 18 71 38 2D 40 58 2C

0x04 45 00 A0 5A 00 00 00 1E 01 1D 00 72 51 D0 1E 20

0x05 6E 28 55 00 A0 5A 00 00 00 1E 00 00 00 FD 00 3A

0x06 3E 1E 53 10 00 0A 20 20 20 20 20 20 ⓓ

0x07 ⓓ00 ⓔ3