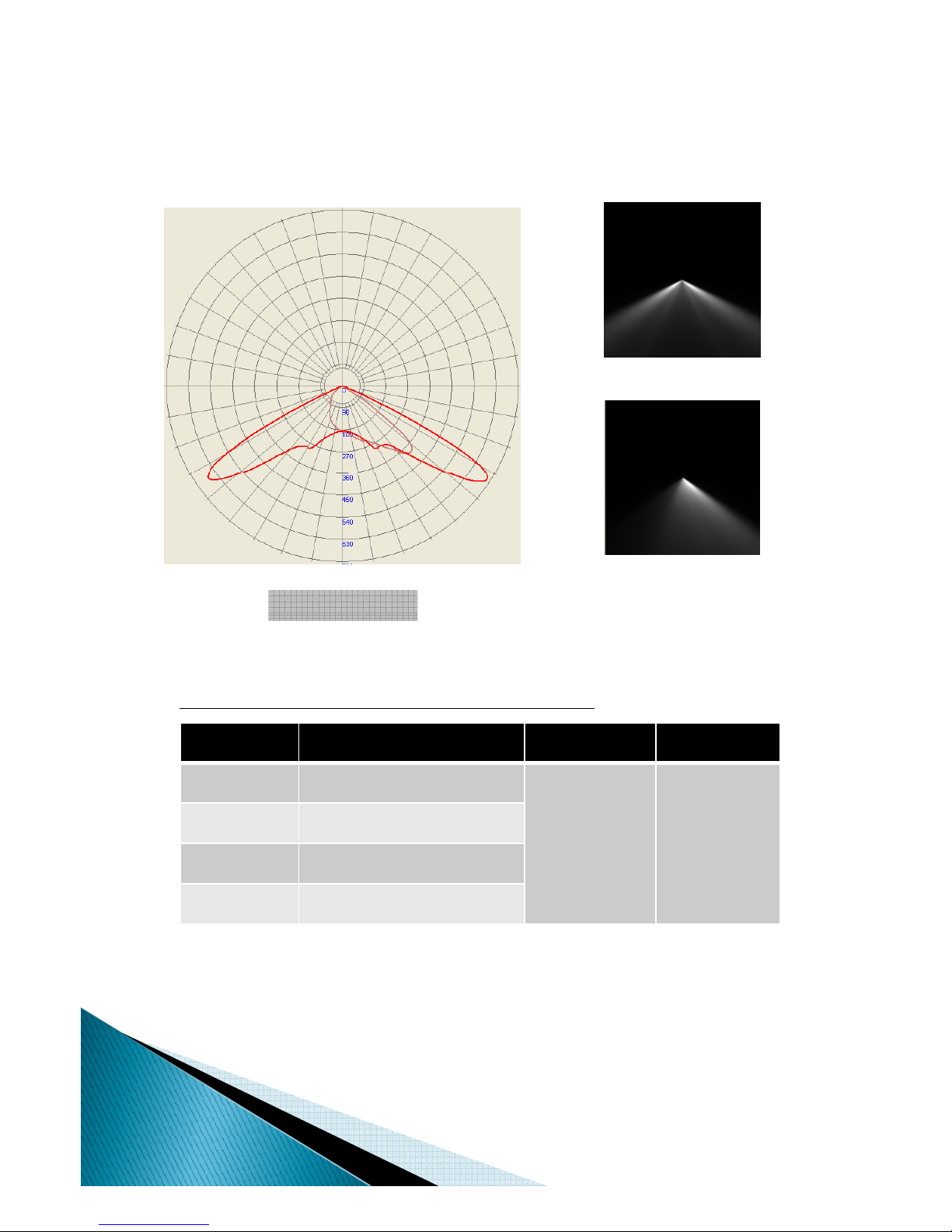

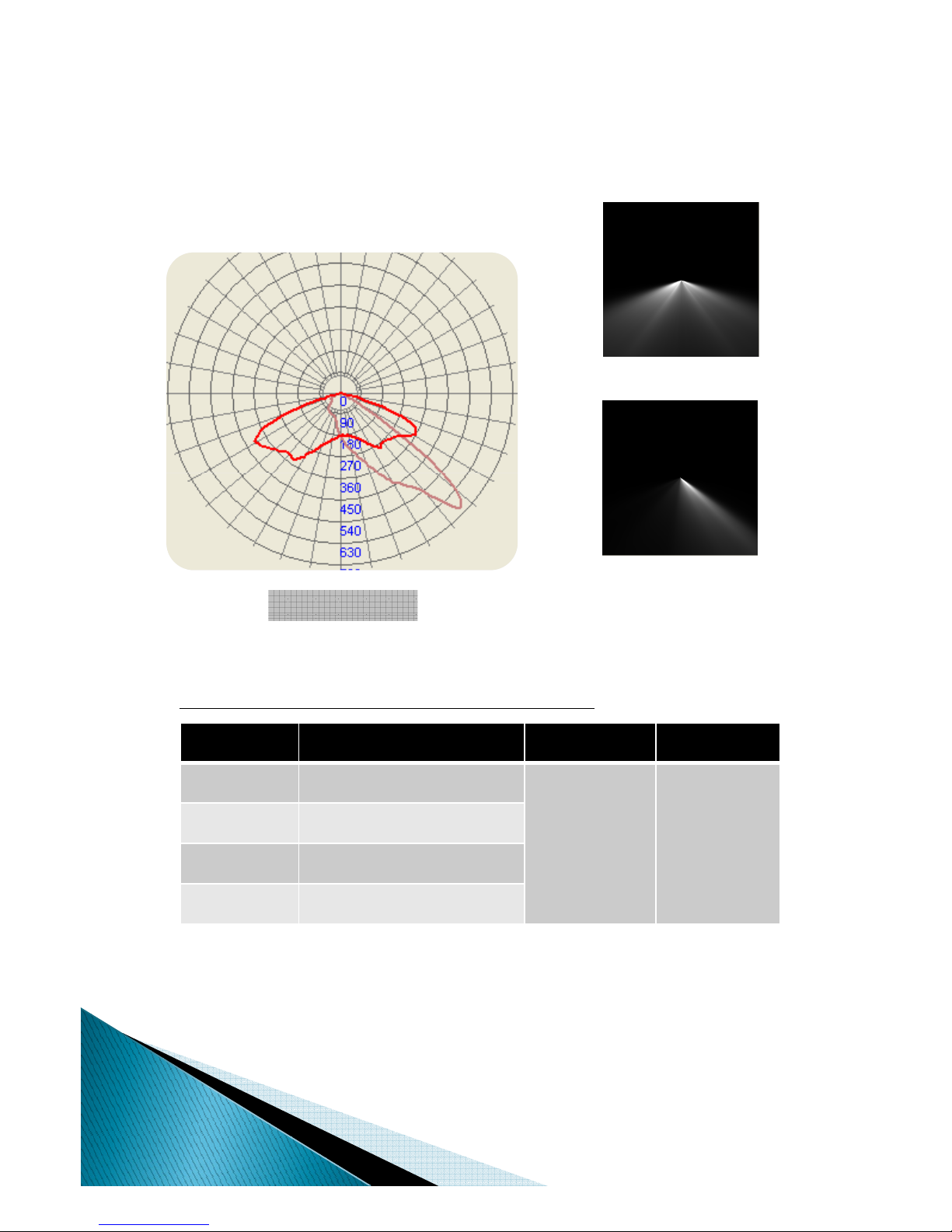

Total Luminous flux Lm 1000↑

Luminous efficiency lm/W 80 ↑

Storage Temperature ºC - 40 ~ 80

Operating Temperature ºC - 40 ~ 50

Module

Spec. Weight g 92 ±3% Connector not included

Power Consumption

(VDC) W12 ±10%

CRI Ra 70

Size mm Φ76.5 11.9T

Material - RoHS Compliance Halogen Free

Life Time hr 50,000 ↑Warranty up to 50,000

IP - IP67

Standards - EN 62031, 62471

UL 8750 CE, UL

◈Models in the Appendix. A are measured to determine all values above with input current 500mA.

◈All values above are measured by the Integrating Sphere of LG Innotek with EC1000S / WT210.

◈All optic values are measured at 10±2sec. in the Integrating Sphere.

◈The Max. permitted input current putting into all models in the Appendix. A. is 650mA.

◈CRI values can have tolerances in the range of 3% caused by Measuring Instruments.

-2-