- 10 - LGE Internal Use OnlyCopyright©2007 LG Electronics. Inc. All right reserved.

Only or training and service purposes

11. Adjustment of White Balance

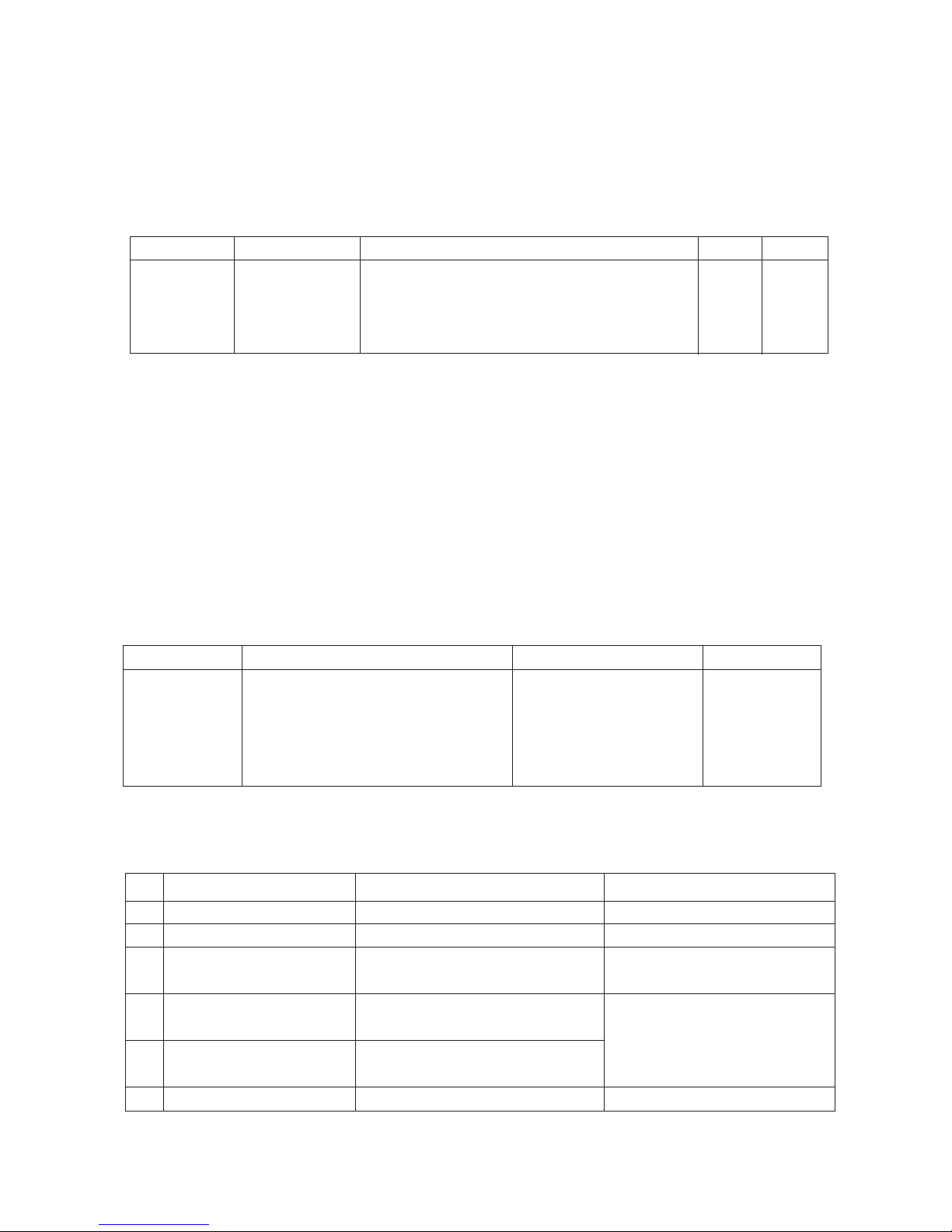

11-1. Requirement

1) Be ore adjusting White-balance , the AV ADC should be

done.

2) I ADC status were “NG”, Need to ADC adjustment.

11-2. Required Equipment

1) Remote controller or adjustment.

2) Color Analyzer.( CA-1000,CA-100,100+,CA-210 or same

product ) : CH10(PDP)

* Please adjust CA-210, CA-100+ by CS-1000 before

measuring.

3) Auto W/B adjustment instrument.(only or Auto adjustment)

4) AV Pattern Generator.

W Color temperature standards according to CSM and Module.

W

CS-1000/CA-100+/CA-210(CH10) White balance adjustment

coordinate and color temperature.

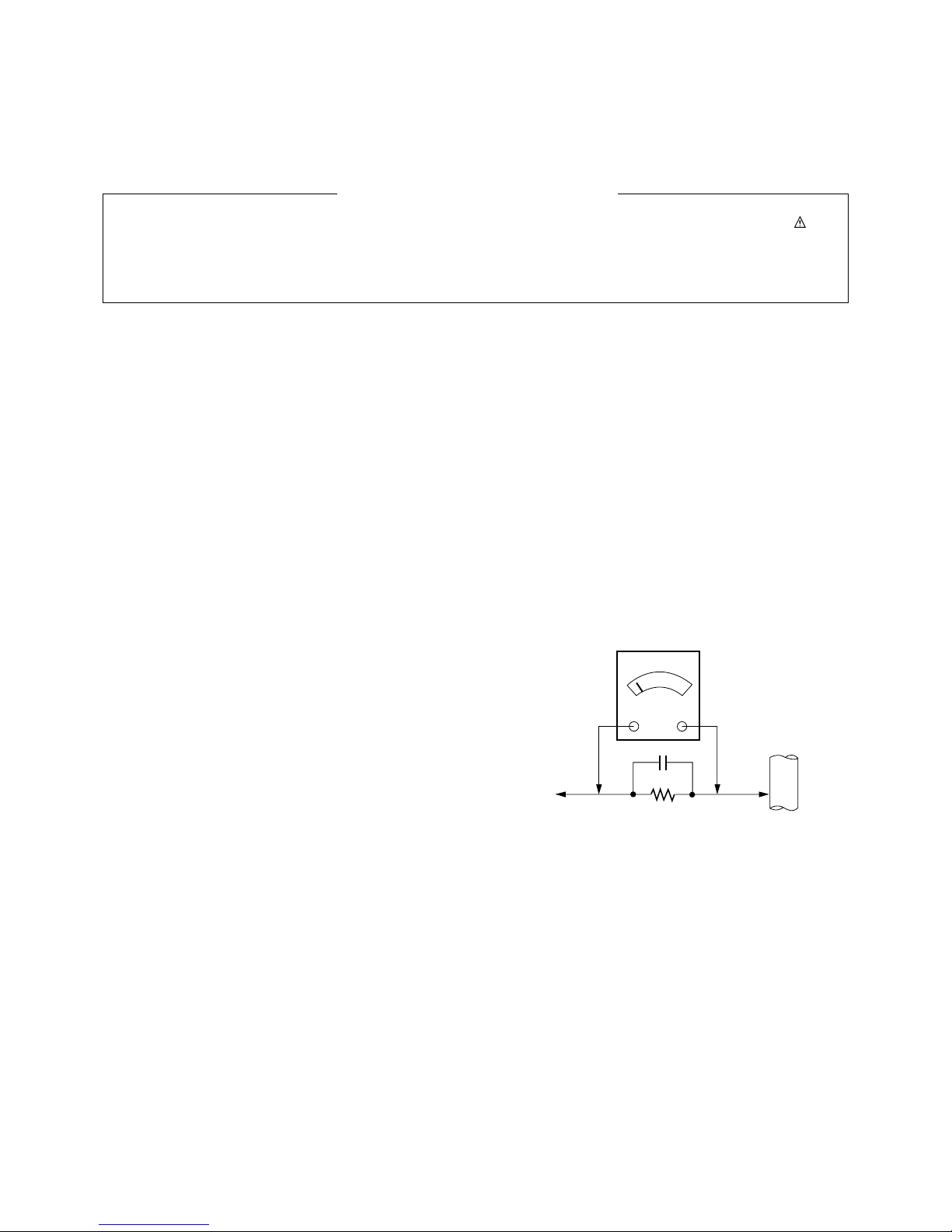

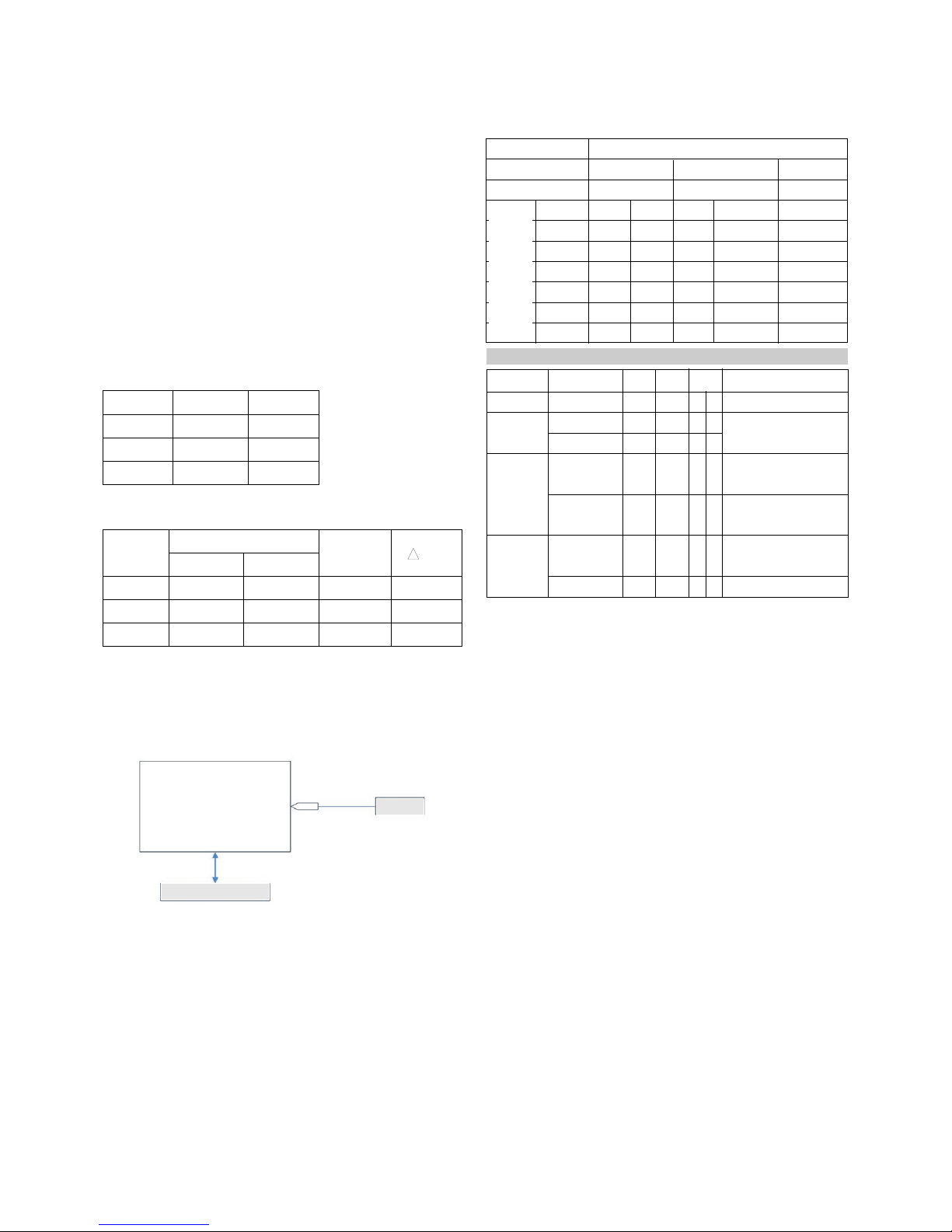

11-3. Connection Picture of the Measuring

Instrument(On Automatic control)

V Inside PATTERN is used when W/B is controlled. Connect

to auto controller or push control R/C IN-START -> Enter

the mode o White-Balance, the pattern will come out.

V Auto-control inter ace and directions

1. Adjust in the place where the in lux o light like loodlight

around is blocked.(illumination is less than 10ux)

2. Measure and adjust a ter sticking the Color Analyzer(CA-

100+, CA210) to the side o the module.

3. Aging time

1) A ter aging start, keep the power on(no suspension o

poewr supply) and heat-run over 15minutes.

2) Keep white pattern using inside pattern.

V Auto adjustment Map(RS-232C)

- Baud : 115200bps, RS232 Host : PC, Echo : none

12. Adjustment of White Balance

(Manual white Balance)

V One o R Gain/ G Gain/ B Gain should be kept on 80, and

others are controlled lowering rom 80

(1) ‘power on’ o the control R/C, set heat run to white by

pressing and heat run over 15 minutes. (Set: RS-232 Host:

PC, Baud Rate: 115200bps, Download: Cortez)

(2) Zero Calibrate CA-100+, and stick the sensor to the center

o PDP module sur ace when you adjust.

(3) Double click In-start key on Controlling R/C and get in

‘white balance’.

(4) Set test-pattern on and display inside pattern. Control is

carried out on three color temperature, COOL, MEDIUM,

WARM. (Control is carried out three times.)

(5) When the R/G/B GAIN is 80 on OSD, it is the FULL

DYNAMIC Range o the Module. In order to control white

balance without the saturation o FULL DYNAMIC Range

and DATA, one o R Gain / G Gain / B Gain should be kept

on 80, and other two is controlled lowering rom 80.

* Color Temperature: Cool, Medium, Warm

(1) When R GAIN is set to 80

- Control G GAIN and B GAIN by lowering rom 80.

(2) When B GAIN is set to 80

- Control R GAIN and G GAIN by lowering rom 80.

(3) When G GAIN is set to 80

- Control R GAIN and B GAIN by lowering rom 80.

One o R Gain / G Gain / B Gain should be kept on 80, and

adjust other two lower than 80.

(When R/G/B GAIN are all 80, it is the FULL DYNAMIC

Range o Module)

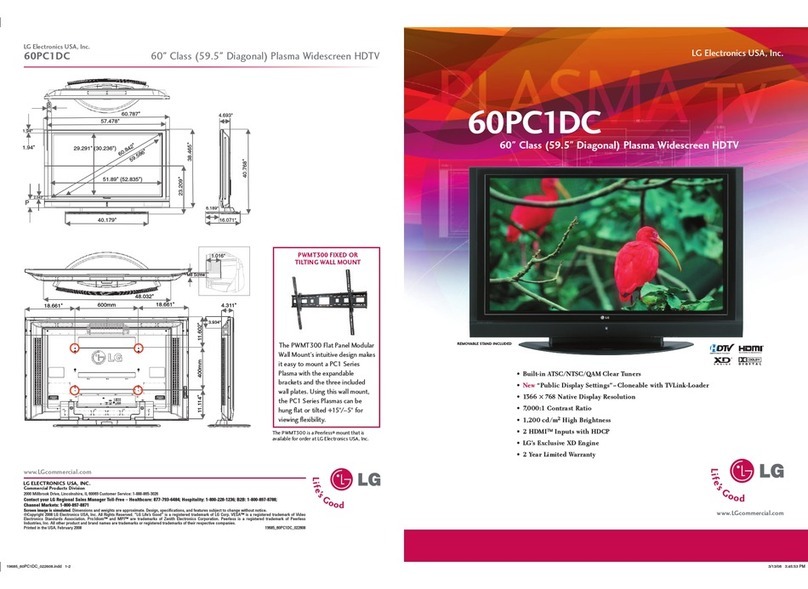

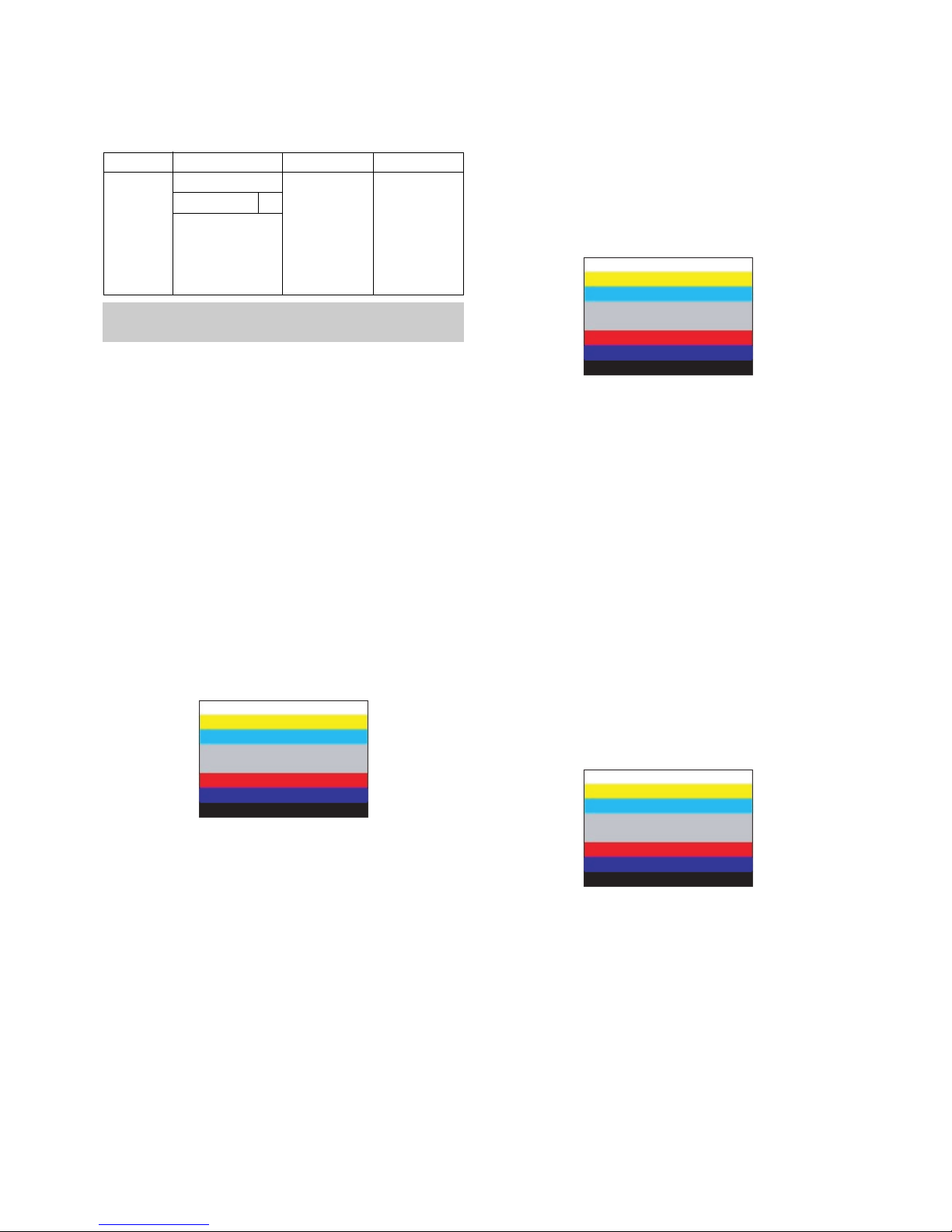

(Fig. 6) Auto AV(CVBS) Color Balance Test Pattern