- 3 -

F ea tures of refrigera nt (R 600a)

•Achromatic and odor less gas.

•F lammable gas and the ignition (explosion) at 494°C .

•Upper/lower explosion limit: 1.8% ~8.4% /V ol.

F ea tures of the R 600a refrigerator

•C harging of 60% refrigerant compared with a R 134a model.

•The suction pressure is below 1bar (abs) during the operation.

•B ecaus e of its low s uction pressure, the external air may ow

in the cycle system when the refrigerant leak, and it caus es

malfunction in the compressor.

•T he dis pla ce ment of compressor us ing R 600a mus t be a t

leas t 1.7 times larger than that of R 134a.

•Any type of dryer is applicable (XH-5, 7, 9).

•The E VAP OR AT OR or any other cycle part that has welding

joint is hidden in the foam. (If not hidden inside, the whole

ele c tric pa rts mus t be te s te d with the L E AK A G E T E S T

according to the IE C S tandard.)

•The compressor has label of the refrigerant R 600a.

•Only the S VC man mus t have an access to the system.

After the refrigerant (R 600a) is completely dis charged,

repair any defective parts and replace the dryer. At any

cas e you must us e the LOK R ING for connecting or replacing

any part in the cycle (No F ire, No Welding). C harge the N2

gas in order to check for leakage from welding points and the

LOK R ING . If leakages are found, repair the defects again.

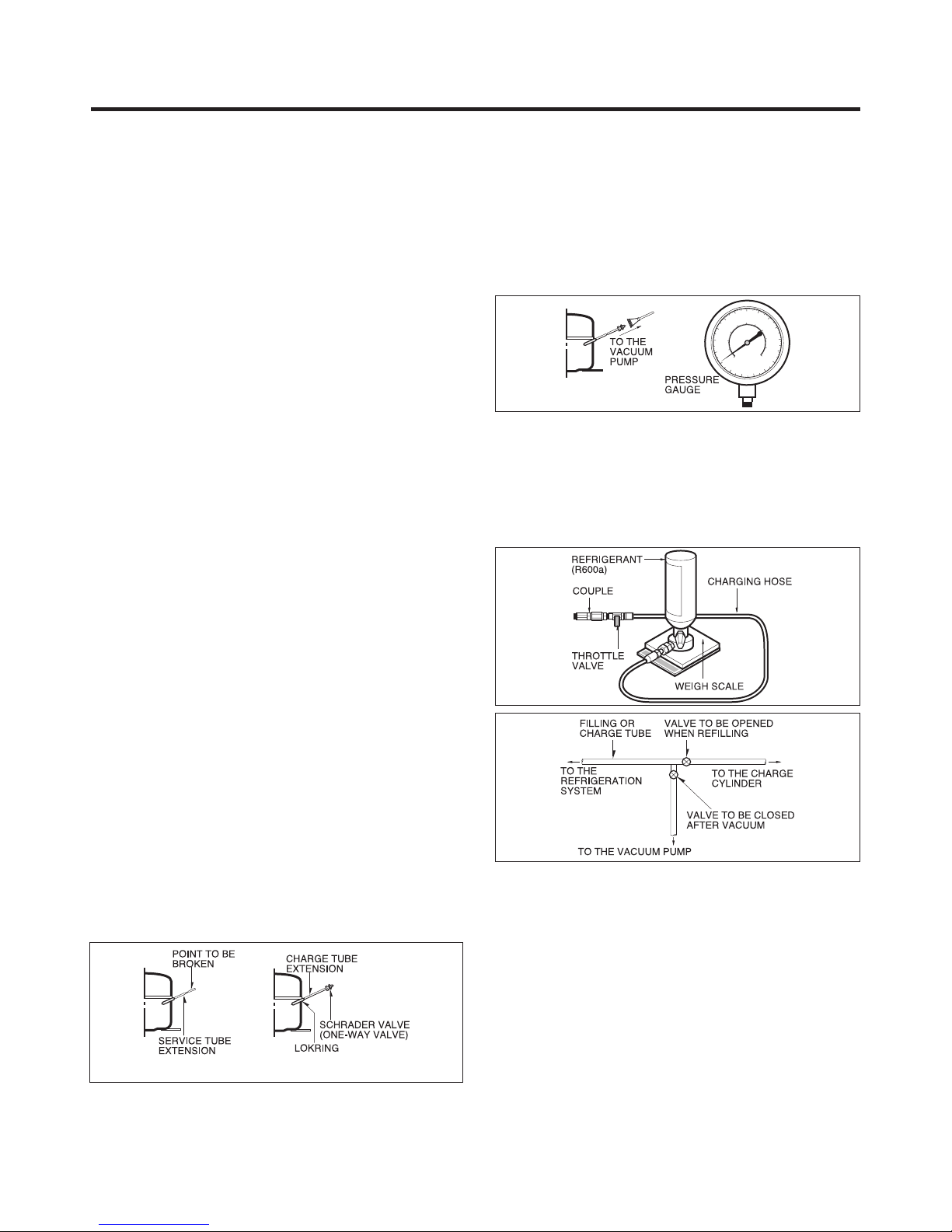

C onnect the S chrader valve to pump with the coupler. And

then turn the pump on for vacuum state (F igure 3). Let the

pump run until the low pressure gauge indicates the vacuum

(gauge pressure -1atm or -760mmHg, absolute pressure 0 ).

R ecommended vacuum time is 30 min.

After the s ys tem is completely va cuume d, ll it with the

refrigera nt R 600a up to what ha s been s pecied at your

refrigerator Name P late. T he amount of refrigerant (R 600a)

mus t be prec is ely mea s ured within the error of ±2g by an

electron scale (F igure 4).

If you us e the manifold connected with both the refrigerant

(R 600a) cylinder and the vacuum pump simultaneous ly, make

sure the pump valve is closed (F igure 5).

C onne c t the c ha r ging hos e ( tha t is c onne c te d to the

refrigerant (R 600a) cylinder) to the S chrader valve ins talled

on the s ervice tube. T hen, charge the refrigerant (R 600a) by

controlling the T hrottle valve. W hen you do s o, do not fully

open the Throttle valve because it may make damage to the

compressor. G ra dua lly cha rge the refrigerant (R 600a ) by

changing open and close the Throttle Valve (5g at each time).

The charging hose must use a one-way valve to prevent the

refrigerant reuence. C lose the S chrader valve cap after the

refrigerant (R 600a) is completely recharged.

A fte r you c omple tely re c ha rge the refrige ra nt ( R 600a ) ,

perform the leakage tes t by using a portable leakage detector

or s oa py wa te r. T e s t the low pre ssure (s uction) pa rts in

compressor o time and high pressure parts in compressor

on time. If the leakages are found, restart from the refrigerant

(R 600a) dis charging process and repairs defects of leaks .

After the leakage tes t, check the temperature of each parts of

the cycle. C heck with hands if the C ONDE NS E R a nd the

cas e (HOT -LINE pipe) that is contacted to the door gas ket

are warm. C onrm that fros t is uniform dis tributed on the

surface of the E V AP OR AT OR .

Ins tallation place

•Must be well ventilated.

•Must be 20 m3or larger.

•Must be no-s moking area.

•No ignitable factors must be pres ent.

Utilities

•R efrigerant cylinder (MAX NE T 300g)

•Manometer

•Vacuum pump (600ℓ/min)

•P iercing C lamp

•Quick coupler

•Hos es (5m-1E A, 1m-3E A)

•LO K R ING

•P ortable Leakage detector (3g/year)

•Nitrogen cylinder (for leakage tes t)

•C oncentration gauge

Make s ure before S ervicing

•R efrigerant

C onrm the refrigerant by checking Name P late and the label

on the compressor, after opening the C OVE R ASSE MB LY ,

B AC K -M/C .

•If the refrigerant is R 600a, you must not weld or apply a heat

source.

Air R echarging in C ompressor

B efore relling the re frigera nt, you mus t perform the tes t

according to C hapter 5 (T R OUB LE S HOOT ING C HAR T ). When

the de fe cts a re found, you mus t dis c ha rge the re s idua l

re frige r a nt ( R 600a ) in the outdoor. F o r dis c ha rging th e

refrigerant R 600a, break the narrow portion of tube extens ion

by hand or with a pipe cutter as shown in Figure 1. Leave it for

30min in outs ide to s tabilize the pressure with ambient. Then,

check the pressure by piercing the dryer part with piercing

pliers . If the refrigerant is not completely discharged, let the

refrigerator alone for more 30min in outs ide.

Attach the s ervice tube installed with a S chrader valve (one-

way valve) by using the LOK R ING (F igure 2). T hen, connect

the S c hra de r va lve ( one -wa y va lve ) to the pump tha t is

connected to the dis cha rging hos e le ading to the outs ide .

When dis charging the res idual refrigerant, repeat 3 cycle that

includes 3min of the pump running->pump o->30s ec of the

compressor running.

F igure 1 F igure 2

F igure 3

F igure 4

F igure 5

S E R VIC ING P R E C AUT IONS