SERVICING PRECAUTIONS

- 3 -

It is necessary to execute the soldering operation with valve

open so that the fumes caused by oil residue can come out

freely without blowholes between two tubes during heating

the point to be soldered.

The extension fitted with the male Hansen is connected to

the female fitting of the vacuum pump tube. (Figure 3)

Air evacuating from the system begins so soon as the pump

starts. The refrigeration system must be kept under vacuum

until the reading on the low-pressure gauge indicates

vacuum (0 absolute, -1 atm., -760 mm hg) in any case it is

advisable to keep the pump running for about 60 minutes.

(Figure 3)

In case that a considerable leakage occurs and to stop the

vacuum pump will be necessary and add a small quantity of

Freon to the system, if vacuum should not be obtained

(pressure gauge can't fall to 1 atmosphere), start the

refrigeration unit and find the leakage with the special leak-

finder. When the defective soldering point is visible, re-do it

after opening the extension tube valve and reestablishing

the normal outside pressure inside the group.

Because the melted alloy is sucked into the tubes and block

them, the pressure must be rebalanced when vacuum is in

the system in soldering. As soon as the vacuum operation

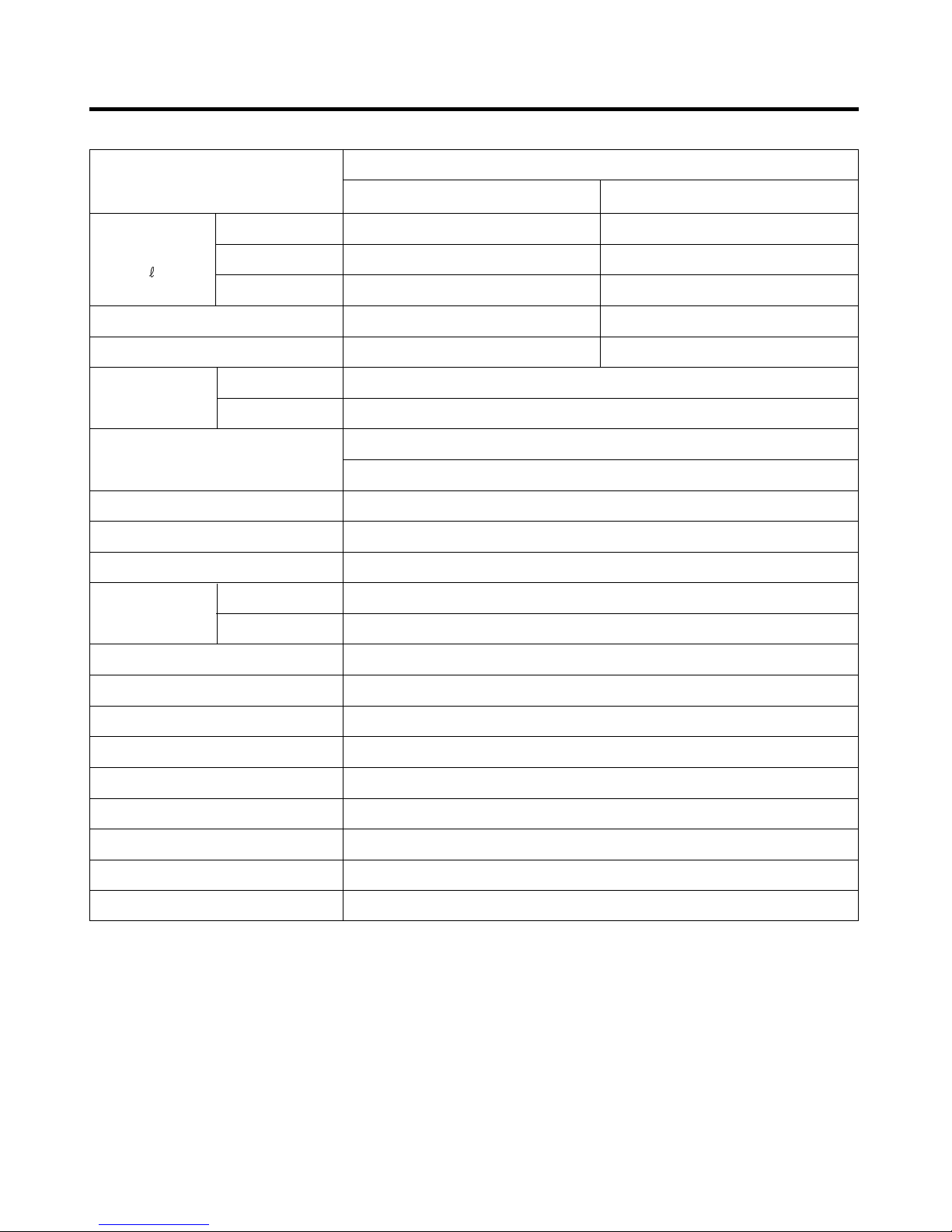

In addition, check the graduated scale on the cylinder for

the quantity of R-134a to be added, for example, if we have

750 grams of Freon in the cylinder and must add 165 grams

to the group, this amount will be reached when R-134a has

dropped to 585 grams, remembering that the indicator

shows a lower limit of meniscus. Do this after choosing the

scale corresponding to the gas pressure different scales

reported as the same gas pressure indicated by the

pressure gauge on the top of the column.

To make R-134a flow into the system, open the valve

placed at the base of the cylinder and connected to the

filling tube. The amount of Freon cannot be added to the

system all at once because it may cause a blocking of

motor-compressor. Therefore, proceed by adding original

quantity of about 20-30 grams and close the valve

immediately.

The pressure rises and the motor-compressor must start,

sucking the gas and making the pressure go down again.

Regulate the valve again, maintaining the same manner

until reaching to the quantity of R-134a established for the

system being charged. When the system is running, the

suction pressure must be stabilized between 0.10 to 0.4

atmosphere.

Before performing this operation (if the vacuum pump and

refilling cylinder are connected), make sure that the valve

placed between the vacuum pump and refilling tube are

closed to keep the Freon for adding to the system. (Figure 5)

POINT TO BE

BROKEN CHARGE TUBE

EXTENSION

MALE HANSEN

TO THE R-134a CYLINDER

SERVICE TUBE EXTENSION SOLDERING POINT

FEMALE

HANSEN TO THE REFRIGERATION

SYSTEM

FILLING OR

CHARGE TUBE

VALVE TO BE OPENED

WHEN REFILLING

TO THE REFRIGERATION

SYSTEM

TO THE VACUUM PUMP

TO THE CHARGE

CYLINDER

VALVE TO BE CLOSED

AFTER VACUUM

TO THE

VACUUM PUMP

PRESSURE

GAUGE

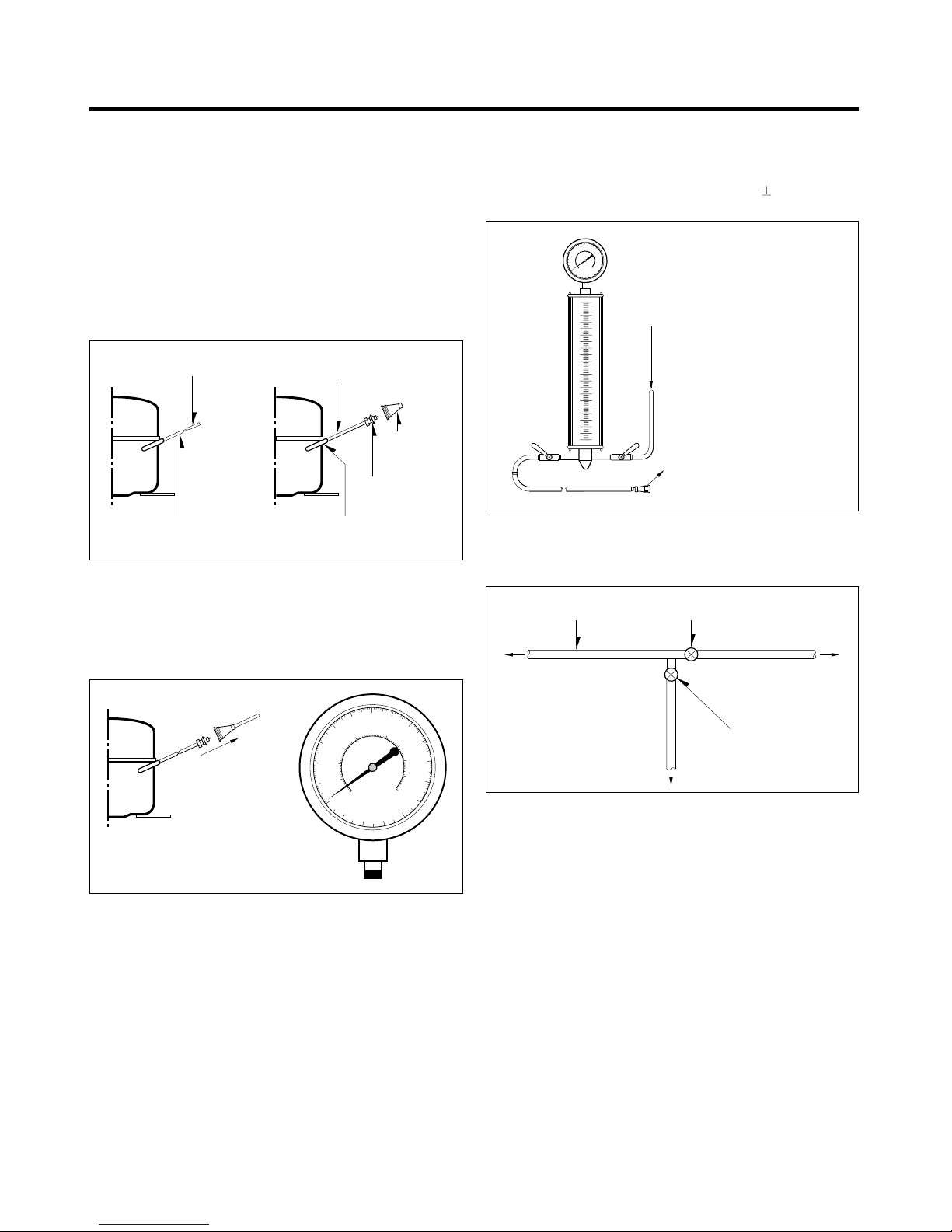

Figure 1 Figure 2

Figure 4

Figure 5

Figure 3

Air Recharging in Compressor

Test the refrigeration by connecting it electrically before

refilling operation. It is necessary to ascertain the function

of the motor-compressor and identify the defects

immediately. If the defects have been found, empty the old

system of eventual R-134a residue by breaking off the end

of the extension piece at its narrow point. (Figure 1)

Replace the filter and any damaged components. Unsolder

and pull off the piece remaining inside the service tube and

then attach an extension completely with male Hansen and

last, solder it to the same tube again. (Figure 2)

is over, add the quantity in grams of R-134a to the

refrigerant system. Remember that every system has an

exact quantity of R-134a with a tolerance of 5 grams that

can be added. (Figure 4)