6

Safety warnings and cautions

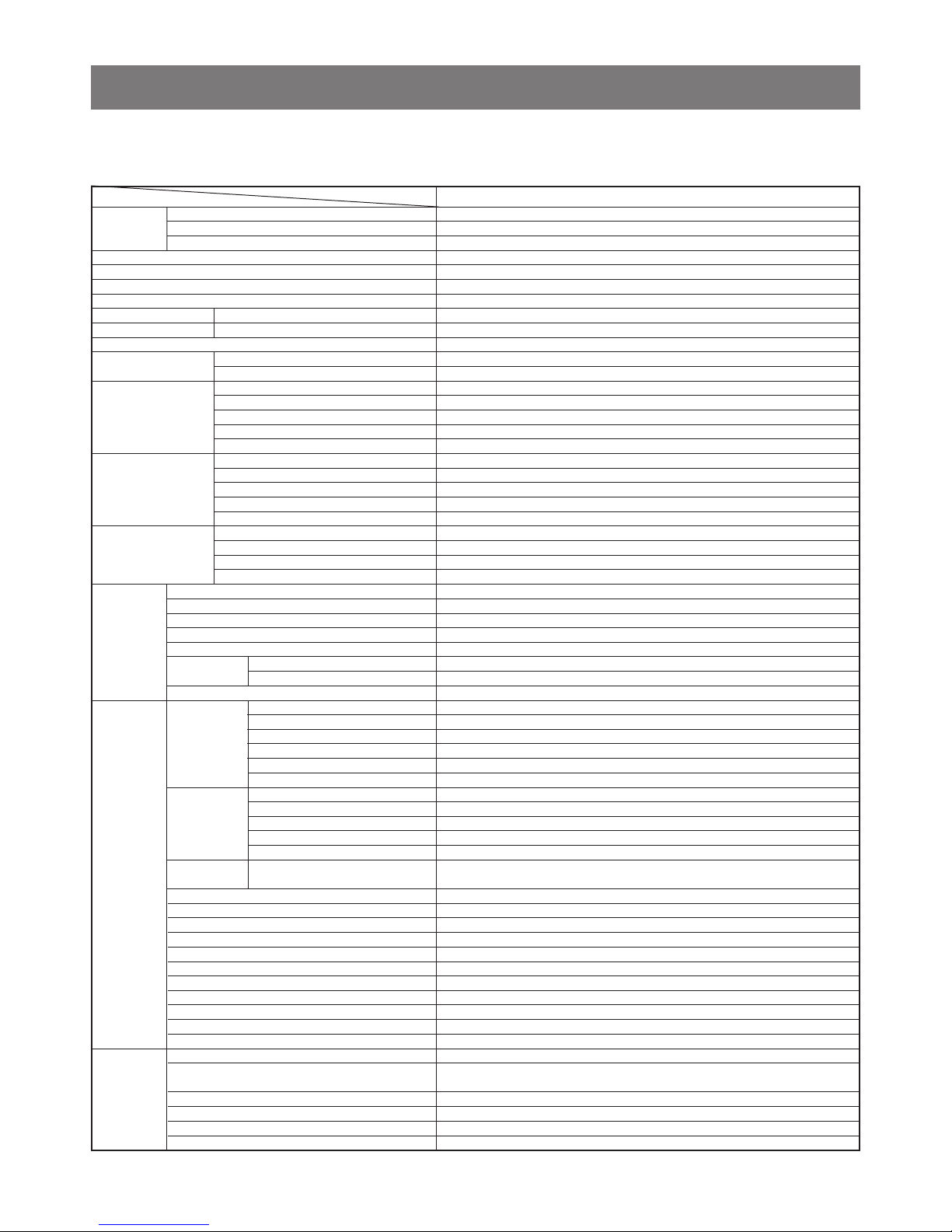

Caution

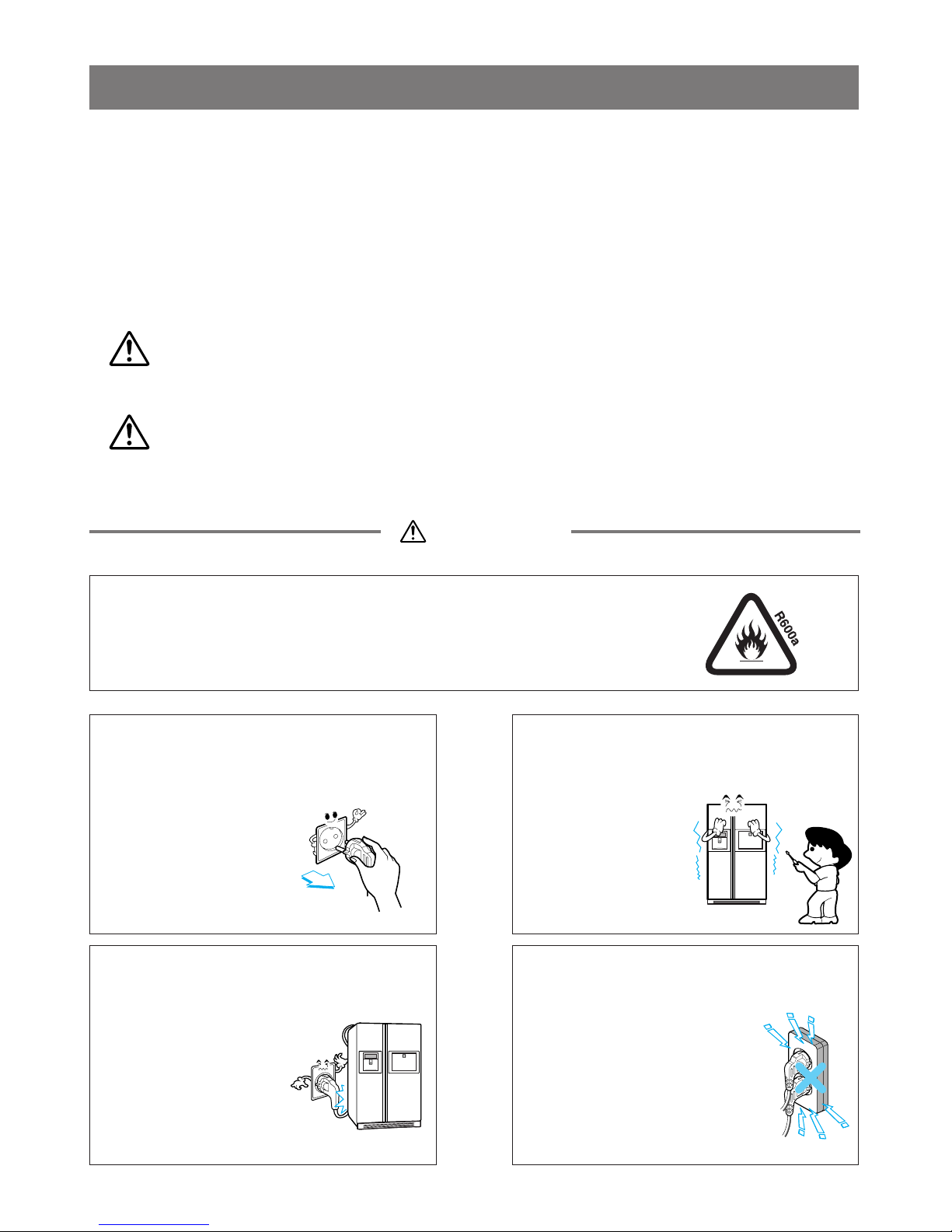

Do put the vessel that flower base,

cup, cosmetics or drugs, etc

are contained on the

refrigerator.

Fire or electric shock may occur, or

injury due to dropping may occur.

Do not accumulate objects on a

refrigerator or do not keep

foods in random method.

Dropping of objects when opening

or closing the door may cause

physical injury.

Do not put bottles, etc in the

freezing room.

There is injury danger due to

icing and breaking of

contents.

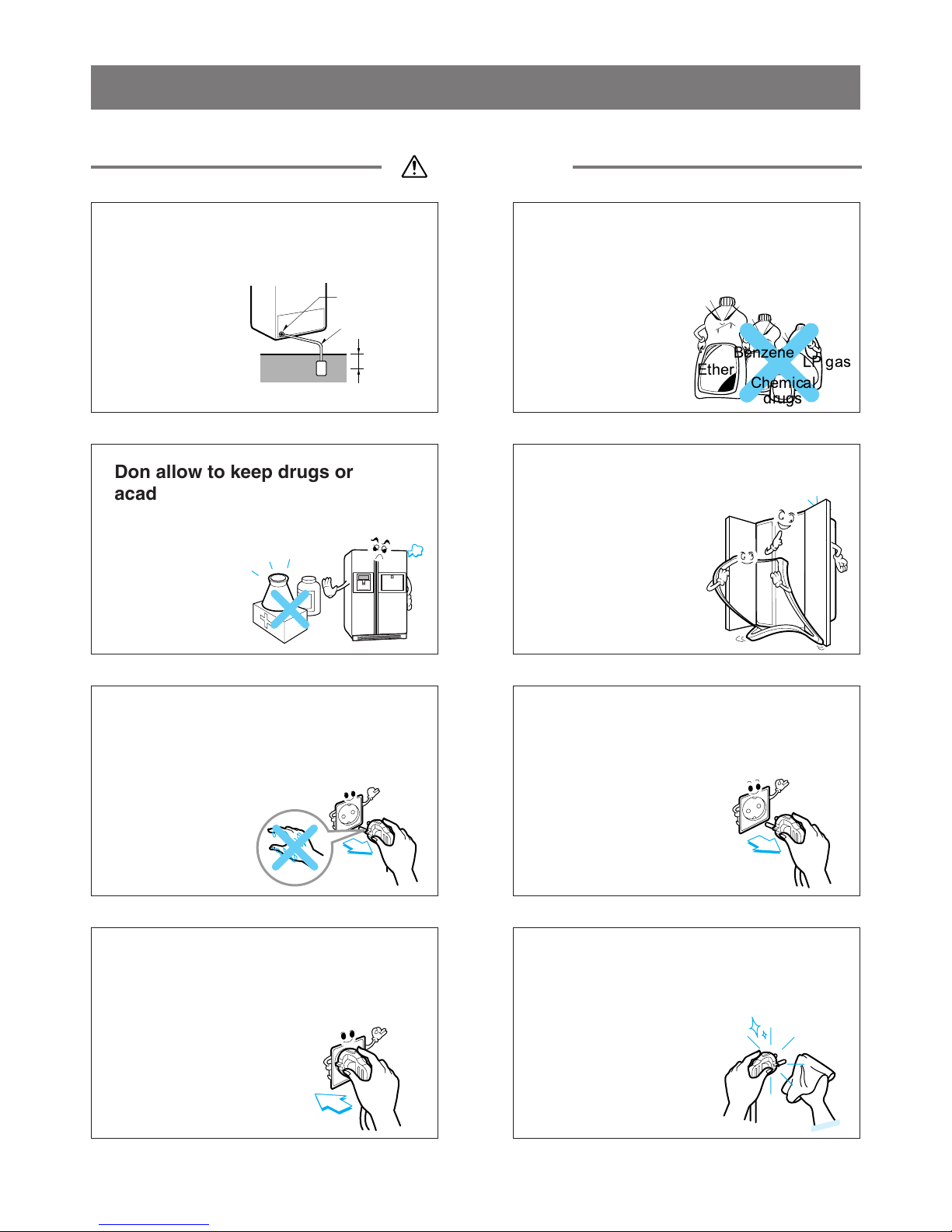

Be sure to rated parts for

replacement of electric parts.

Check marking of model, rated voltage, rated

current, operation temperature, etc of

electrical parts.

Accurately arrange wiring of the

housing part for failure repair.

Check that the hanging

part of the housing part

is firmly suspended.

Do not damage, process or forcedly

bend, take out or twist power cords.

Damage of power cords may

cause fire or electric shock.

Entirely remove dusts or foreign

materials from housing part, wiring

part and checking part, etc for

failure repair.

Danger of fire can be

prevented from tracking, short, etc.

Check assembling status of parts

after failure repair.

Parts should show same status

before repair.

Check that there is a track that

moisture is penetrated into electric

parts.

If there is a track that moisture is penetrated,

replace parts or take a necessary step such

as insulation tapping.

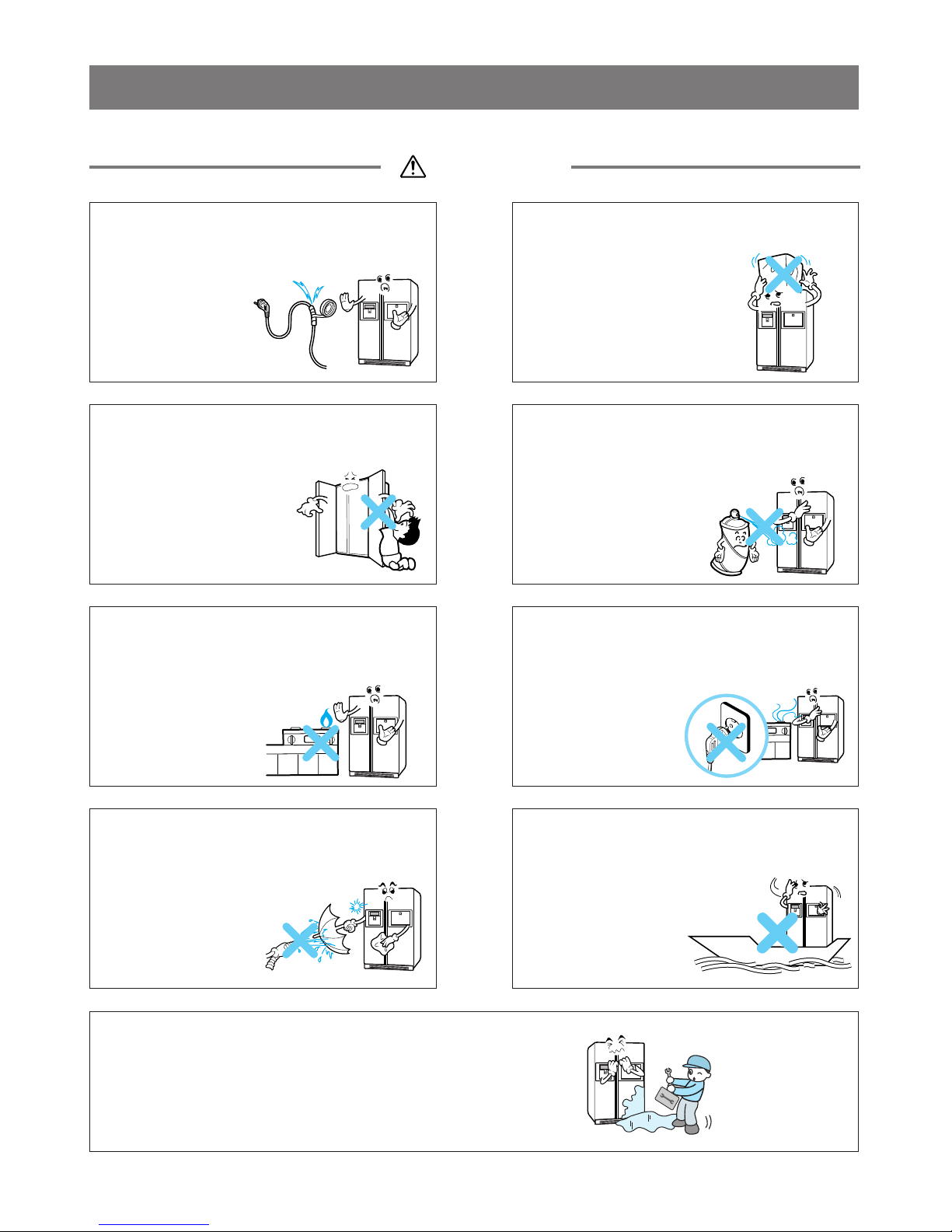

Insert power plug into a socket

after more than 5 minutes pass

when taking out plugs and

then inserting them again.

Unreasonable operation of a

compressor may cause failure.

Do not put the hands or tools, etc into the

ice discharging outlet to check proper

operation of the ice feeding motor.

Damage of parts or injury of the hands may occur.