Safety Precautions

Service Manual 3

Safety Precautions

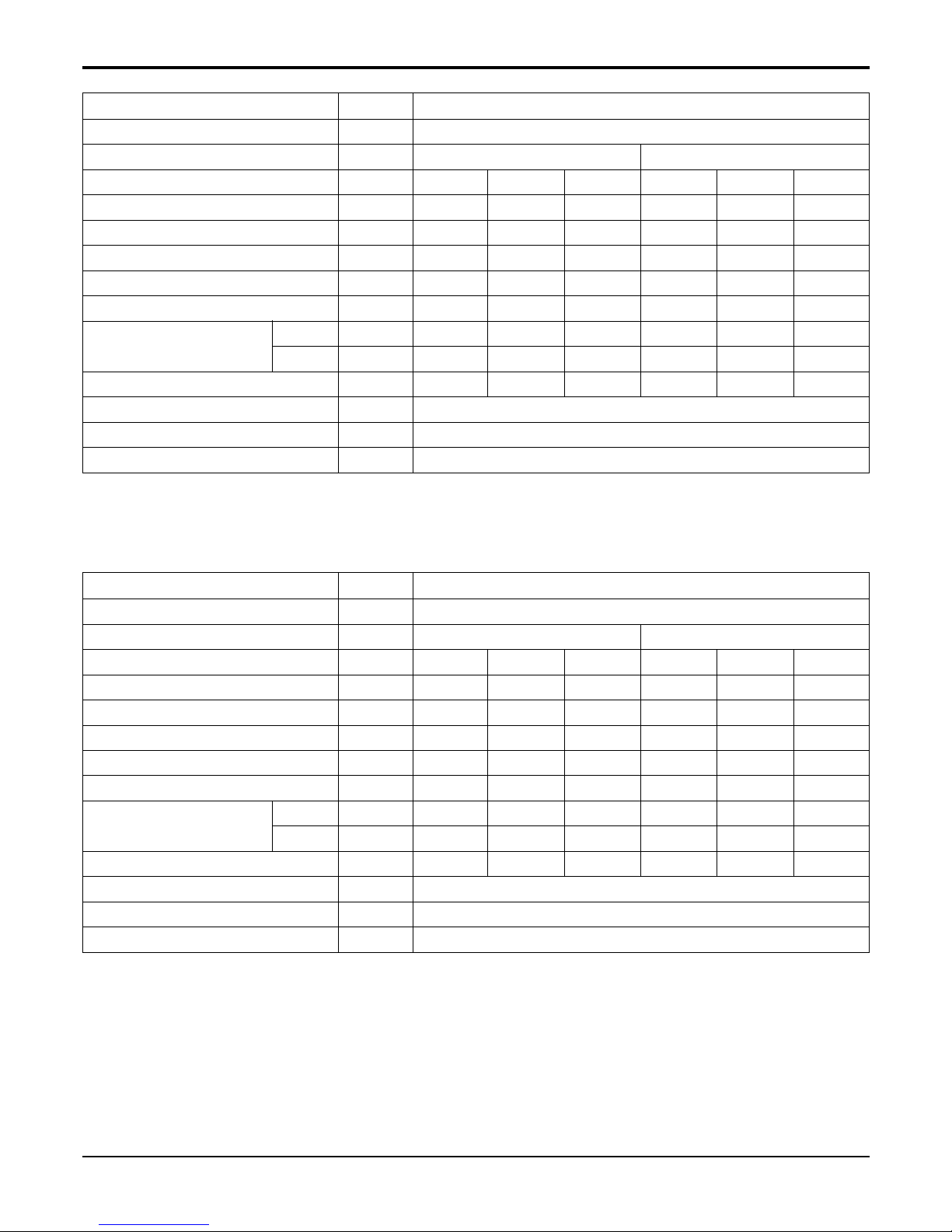

To prevent injury to the user or other people and property damage, the following instructions must

be followed.

■Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is

classified by the following indications.

■Meanings of symbols used in this manual are as shown below.

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage.

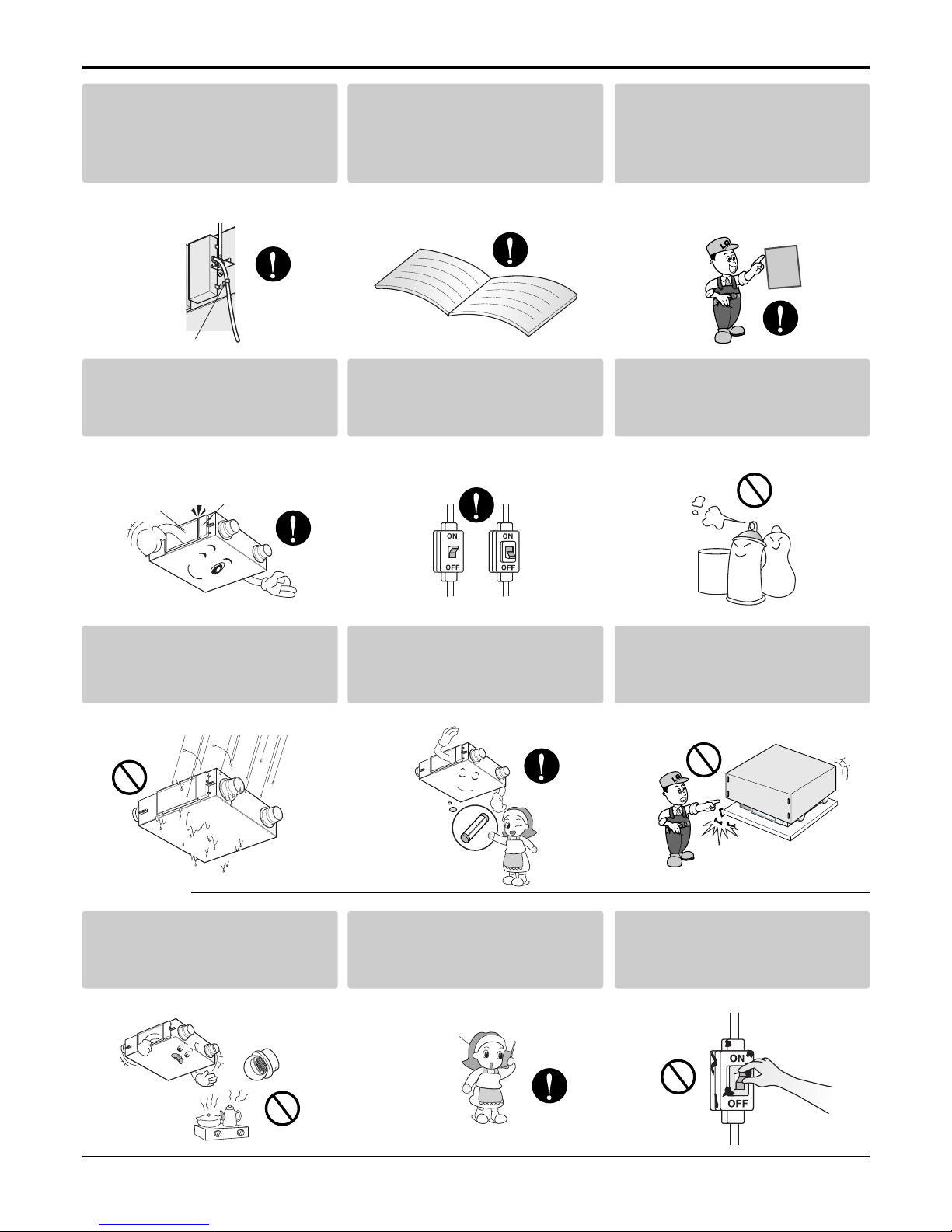

■For Installation

Be sure not to do.

Be sure to follow the instruction.

For electric working(wiring work),

contact Service Center or agency

you purchased the product.

• If you disassemble of repair

arbitrarily, it may cause fire or

electric shock.

Install in a place capable of the

product's weight.

• If the product is installed in a place

incapable of its weight, it may cause

an accident by its dropping.

Do not arbitrarily disassemble,

repair, or modify the product.

• It may cause fire or electric shock.

Be sure to undertake

grounding work.

• If you do not undertake grounding

work, it may cause electric shock.

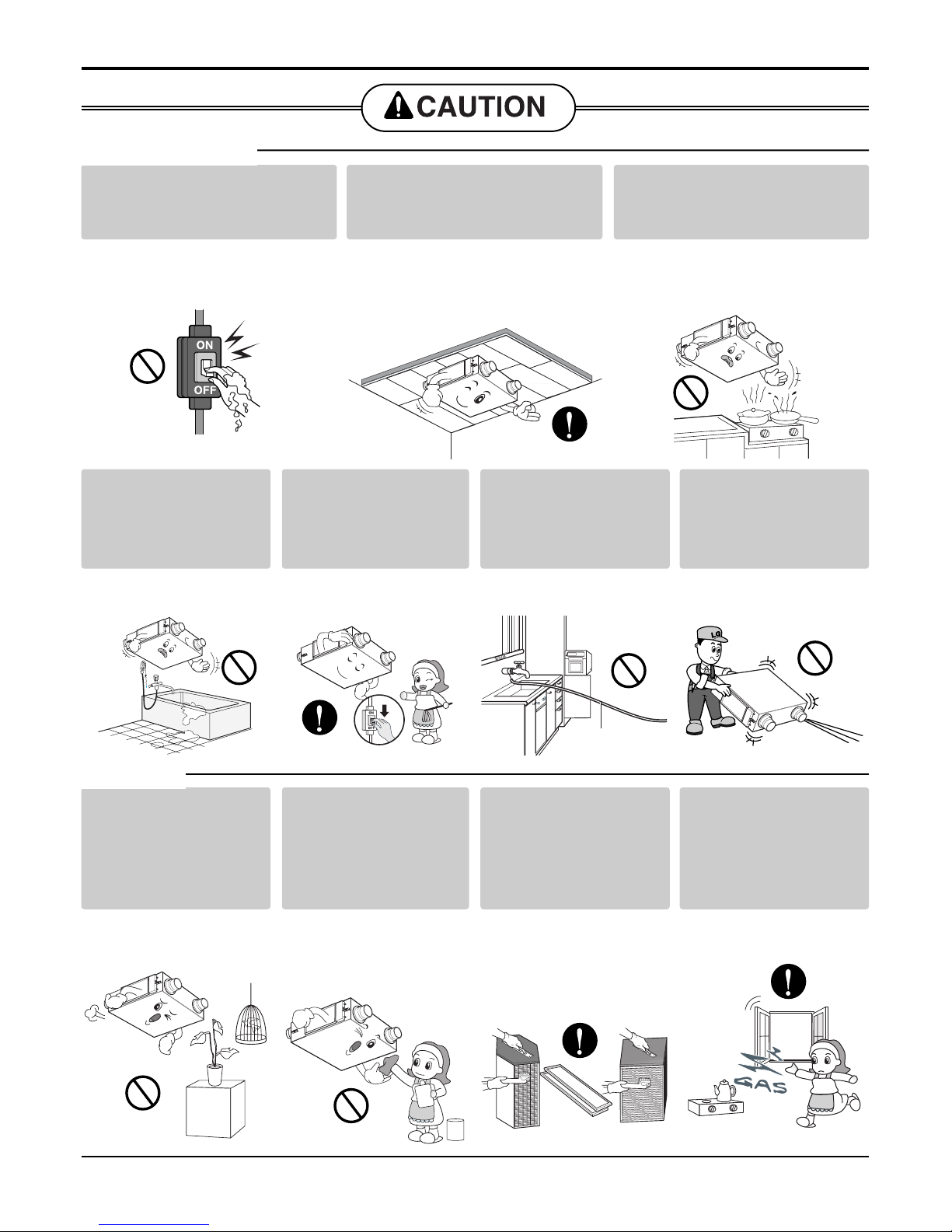

Use an netted inlet for

external air to prevent birds

from entering.

• Remove any clogs such as bird nest.

It may cause an oxygen deficiency in

a room.

Install the air intake where

polluted air can not be directly

sucked in.

• It may cause various accidents,

including suffocation, due to the

suction of harmful gasses(CO, etc.)