CONTENTS

1. S ECIFICATION............................................................................................................................3

2. FEATURES & TECHNICAL EX LANATION ................................................................................ 4

3. ARTS IDENTIFICATION ............................................................................................................ 6

4. INSTALLATION ............................................................................................................................. 7

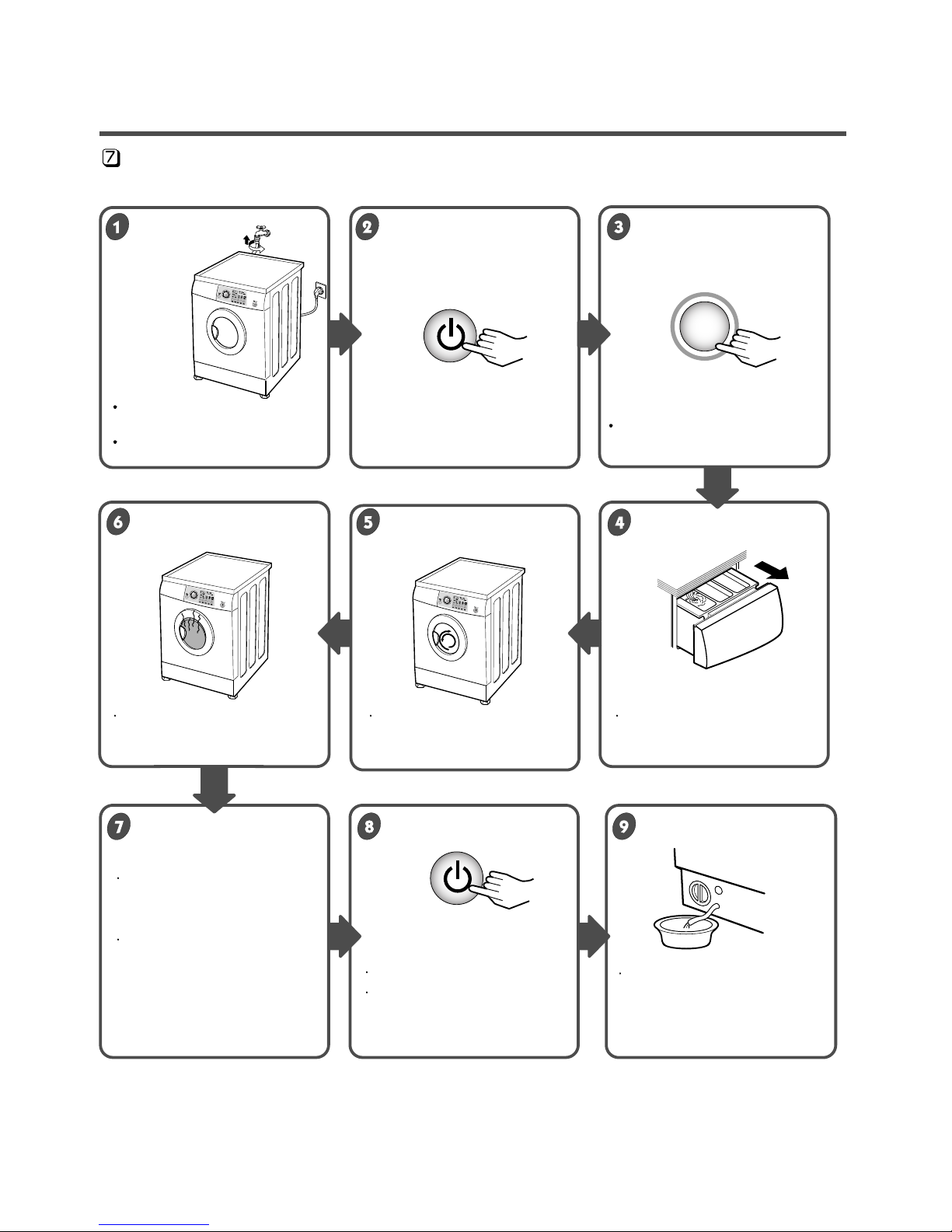

5. O ERATION ................................................................................................................................10

6. WIRING DIAGRAM / ROGRAM CHART...................................................................................14

7. TROUBLE SHOOTING................................................................................................................15

7-1.BEFORE SVC CHECKING ..................................................................................................15

7-2.QC TEST MODE..................................................................................................................15

7-3.HOW TO KNOW THE WATER LEVEL FREQUENCY.........................................................15

7-4.ERROR DIS LAY ................................................................................................................16

8. ERROR DIAGNOSIS AND CHECK LIST ....................................................................................18

8-1. DIAGNOSIS AND ANSWER FOR ABNORMAL O ERATION ...........................................18

8-2. FAULT DIAGNOSIS AND TROUBLE SHOOTING .............................................................21

9. DISASSEMBLY INSTRUCTIONS ...............................................................................................31

10. EX LODED VIEW AND ARTS LIST .......................................................................................41

10-1. THE EX LODED VIEW OF CABINET ASSEMBLY .........................................................41

10-2. THE EX LODED VIEW OF CONTROL ANEL AND DIS ENSER ASSEMBLY ............42

10-3. THE EX LODED VIEW OF DRUM AND TUB ASSEMBLY .............................................43

10-4. THE EX LODED VIEW OF DRYER ................................................................................44

APPENDIX (Replacement parts list) ...........................................................................................45

2