2

CONTENTS

1. SPECIFICATION .......................................................................................................................................3

2. FEATURES &TECHNICAL EXPLANATION ...........................................................................................4

3. PARTS IDENTIFICATION .........................................................................................................................

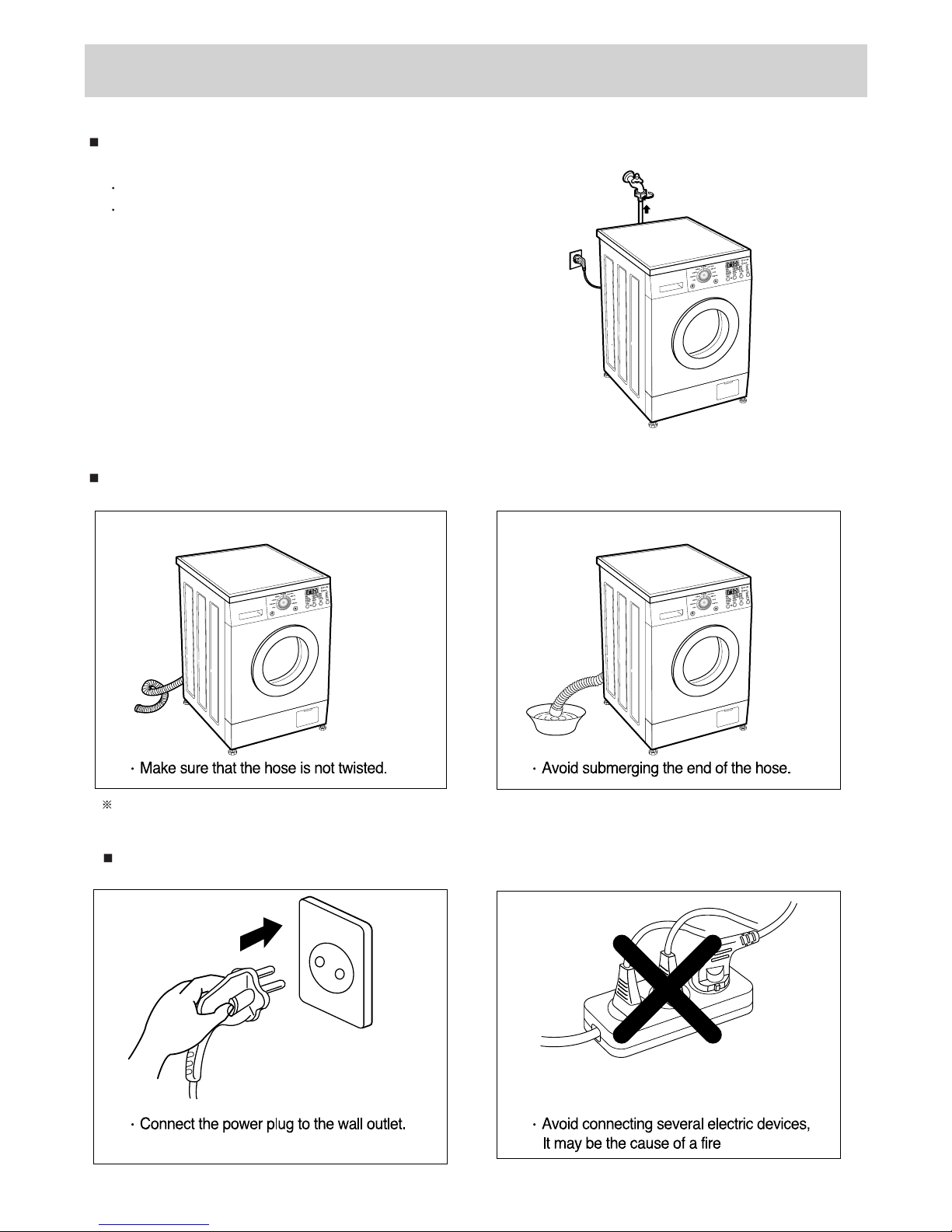

4. INSTALLATION...........................................................................................................................................7

5. OPERATION ...........................................................................................................................................10

. WIRING DIAGRAM /PROGRAM CHART..............................................................................................12

7. TROUBLESHOOTING.............................................................................................................................13

7-1. BEFORE PERFORMING SERVICE ...............................................................................................13

7-2. QC TEST MODE...............................................................................................................................13

7-3. HOW TO KNOW THE WATER LEVEL FREQUENCY..................................................................13

7-4. ERROR DISPLAY ............................................................................................................................14

8. ERROR DIAGNOSIS AND CHECK LIST ..............................................................................................1

8-1. DIAGNOSIS AND ANSWER FOR ABNORMAL OPERATION.....................................................1

8-2. FAULT DIAGNOSIS AND TROUBLESHOOTING .........................................................................19

9. DISASSEMBLY INSTRUCTIONS...........................................................................................................25

10. EXPLODED VIEW AND PARTS LIST..................................................................................................32

10-1. THE EXPLODED VIEW OF CABINET ASSEMBLY .................................................................32

10-2. THE EXPLODED VIEW OF CONTROL PANEL AND DISPENSER ASSEMBLY ..................33

10-3. THE EXPLODED VIEW OF DRUM AND TUB ASSEMBLY .....................................................34

APPENDIX (Replacement parts list) ......................................................................................................35