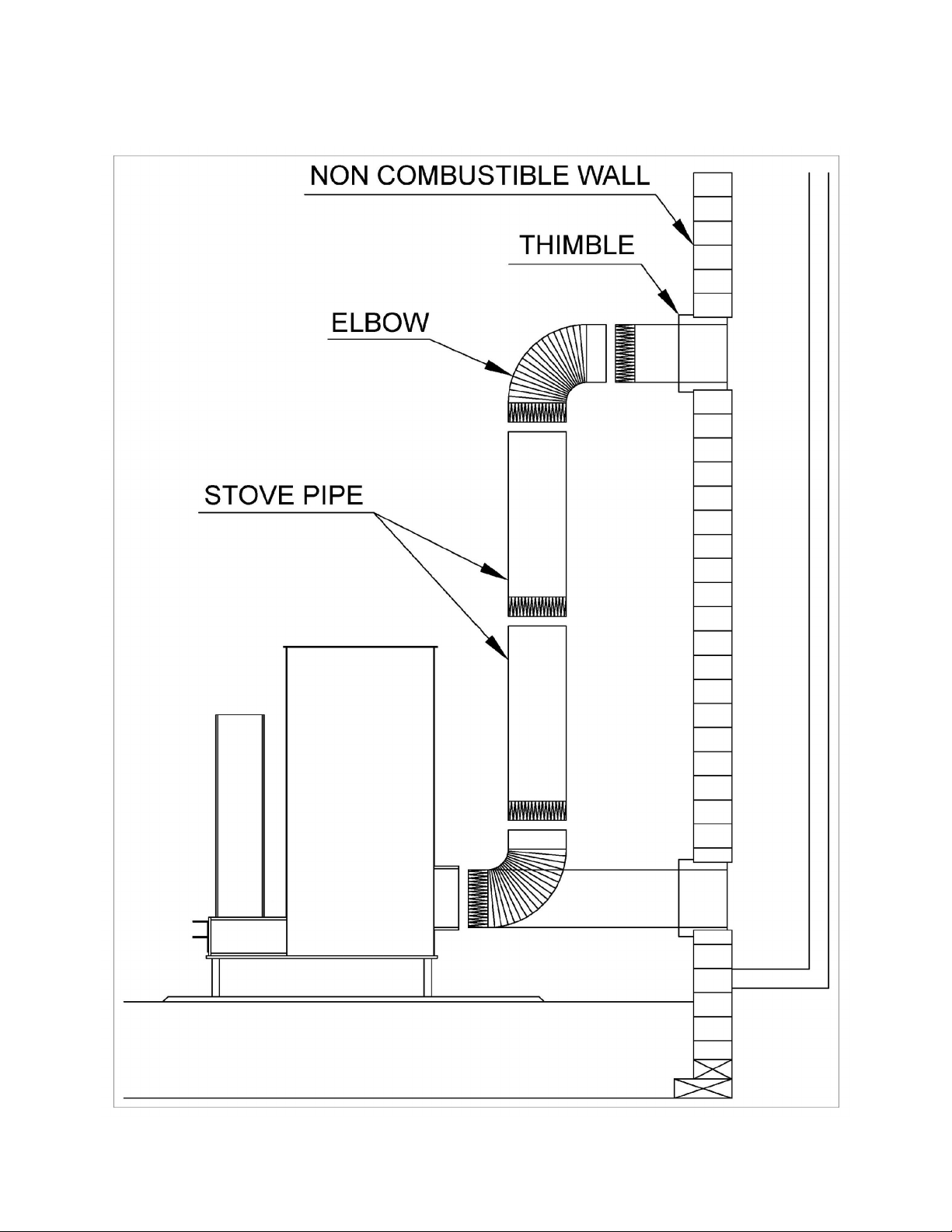

Chimney Connection

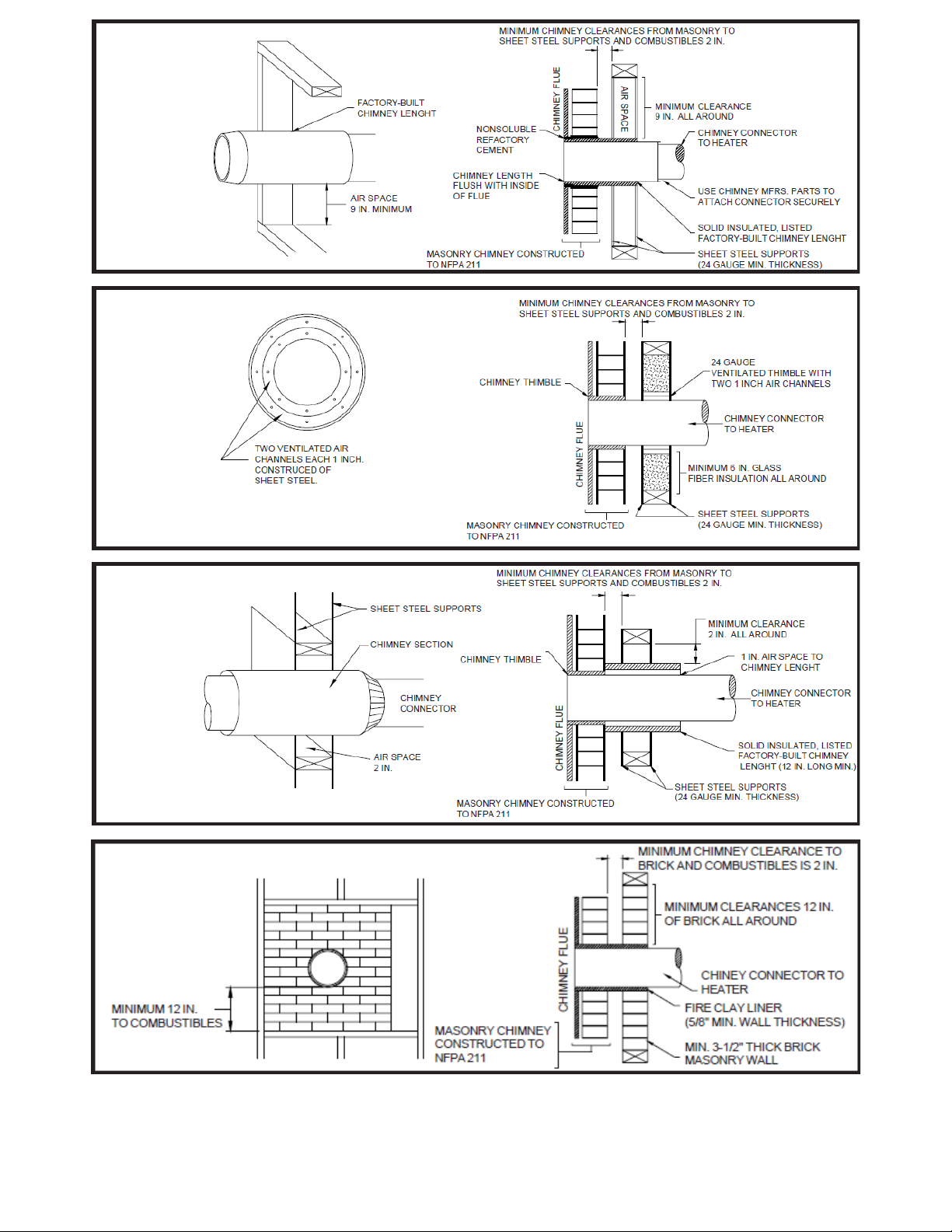

Masonry Chimney

The masonry chimney must comply with UL or equivalent NRTL and NFPA 211 standards and codes. Before using

an existing masonry chimney, clean the chimney and inspect the flue liner to be absolutely sure it is safe to use.

Rules For Connecting To A Masonry Chimney

1. Use a minimum of 3-1/2" inch brick masonry wall framed to a combustible wall. A fireclay liner

(ASTM 13 or equivalent) having a /8" inch minimum wall thickness must be used and it must

be at least 12" inches (1' foot) away from any material that could catch fire. The inside diameter

of the fire clay liner shall be sized for the proper snug fit to a 6" inch diameter chimney

connector pipe. The fireclay liner shall run to, but not beyond, the inner surface of the chimney

flue and be firmly cemented in place.

2. Use a solid insulated listed factory built chimney length having an inside diameter of 6" inches

and having 1" inch or more of solid insulation. There must be at least a 9" inch air space

between the outer wall of the chimney length and any combustible materials. The inner end of

the chimney length shall be flush with the inside of the masonry chimney flue which shall be

sealed to the flue and to the brick masonry penetration with non water-soluble refractory

cement. Flash sheet steel supports which are at least 24 gauge (0.02 " inches) in thickness shall

be securely fastened to wall surfaces on all sides. Fasteners between supports and the chimney

length shall not penetrate the chimney liner.

3. Use a 10" inch diameter ventilated thimble made of at least 24 gauge (0.02 " inch) steel having

two (2) 1" inch air channels. The ventilated thimble must be separated from combustible

materials by at least 6" inches of glass fiber insulation. The opening in the combustible wall

shall be covered and the thimble supported with sheet steel supports which are at least 24 gauge

(0.02 " inch) in thickness. The sheet steel supports shall be securely fastened to wall surfaces

on all sides and shall be sized to fit and hold the chimney section. Fasteners used to secure

chimney sections shall not penetrate the chimney flue liner.

4. Use an 8" inch diameter solid insulated listed factory-built chimney length which has 1" inch or

more solid insulation. The minimum length of the chimney section shall be 12" inches and will

serve a pass through for the 6" inch diameter chimney connector. There must be at least a 12"

inch air space between the outer wall and the chimney section and any combustible materials.

The chimney section shall be concentric with and spaced 1" inch away from the chimney

connector by means of sheet steel support plates on both ends of the chimney section. The

opening in the combustible wall shall be covered and the chimney section supported on both

sides with sheet metal supports which are at least 24 gauge (0.02 " inches) in thickness. The

sheet steel supports shall be securely fastened to wall surfaces on all sides and shall be sized to

fit and hold the chimney section. Features used to secure chimney sections shall not penetrate

chimney flue liner.

. A UL or NRTL listed factory-built wall pass-through system may be purchased and installed

according to the instruction supplied with it to provide a safe method of passing the chimney

connector through a combustible wall for connection to a masonry chimney.

Please See the Following Pages for Diagrammatic Details

and Clearances for Masonry Chimney Installation

Page 7