Table of content

Safety- and operatin instructions........................................................................................ 4

Quick start uide.................................................................................................................. 8

Identification....................................................................................................................... 14

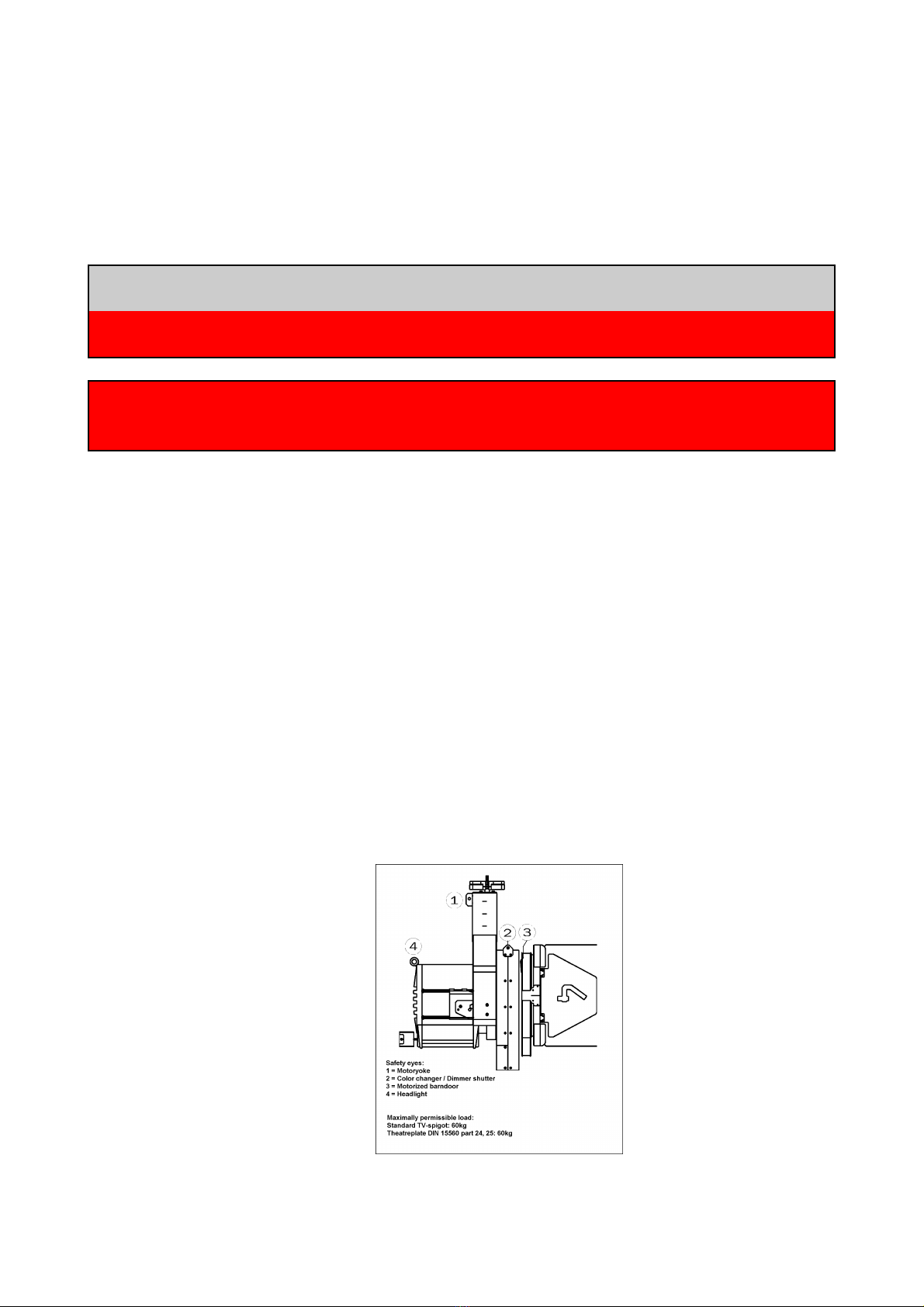

The Licht-Technik Motoryoke............................................................................................. 14

The DMX-standard in li htin ............................................................................................. 15

Cablin ............................................................................................................................... 16

Gettin started.................................................................................................................... 19

PAN – axis movin ran e................................................................................................... 20

User interface..................................................................................................................... 24

Display li htin ON/OFF..................................................................................................... 24

DMX channels motoryoke.................................................................................................. 25

P01 DMX-Address motoryoke............................................................................................ 26

P02 Focus unit ON/OFF..................................................................................................... 27

P03 Focus unit auto adjust (0% and 100%)....................................................................... 28

P05 PAN-axis middle position............................................................................................ 29

P06 TILT-axis 0-position..................................................................................................... 30

P11 PAN-axis movin ran e............................................................................................... 31

P12 TILT-down (ne ative) movin ran e............................................................................ 32

P13 TILT-up (positive) movin ran e.................................................................................. 33

P14 Focus unit 0%-value adjustment................................................................................. 34

P15 Focus unit 100%-value adjustment............................................................................. 35

P27 Speed PAN/TILT setup............................................................................................... 36

P30 Displayin the DMX-value........................................................................................... 37

P32 Selectin the user lan ua e....................................................................................... 38

P35 Unit number Netspider................................................................................................ 39

P36 Interchan in PAN movin direction........................................................................... 40

P37 Interchan in TILT movin direction........................................................................... 41

P38 Interchan in Focus movin direction........................................................................ 42

Technical data.................................................................................................................... 43

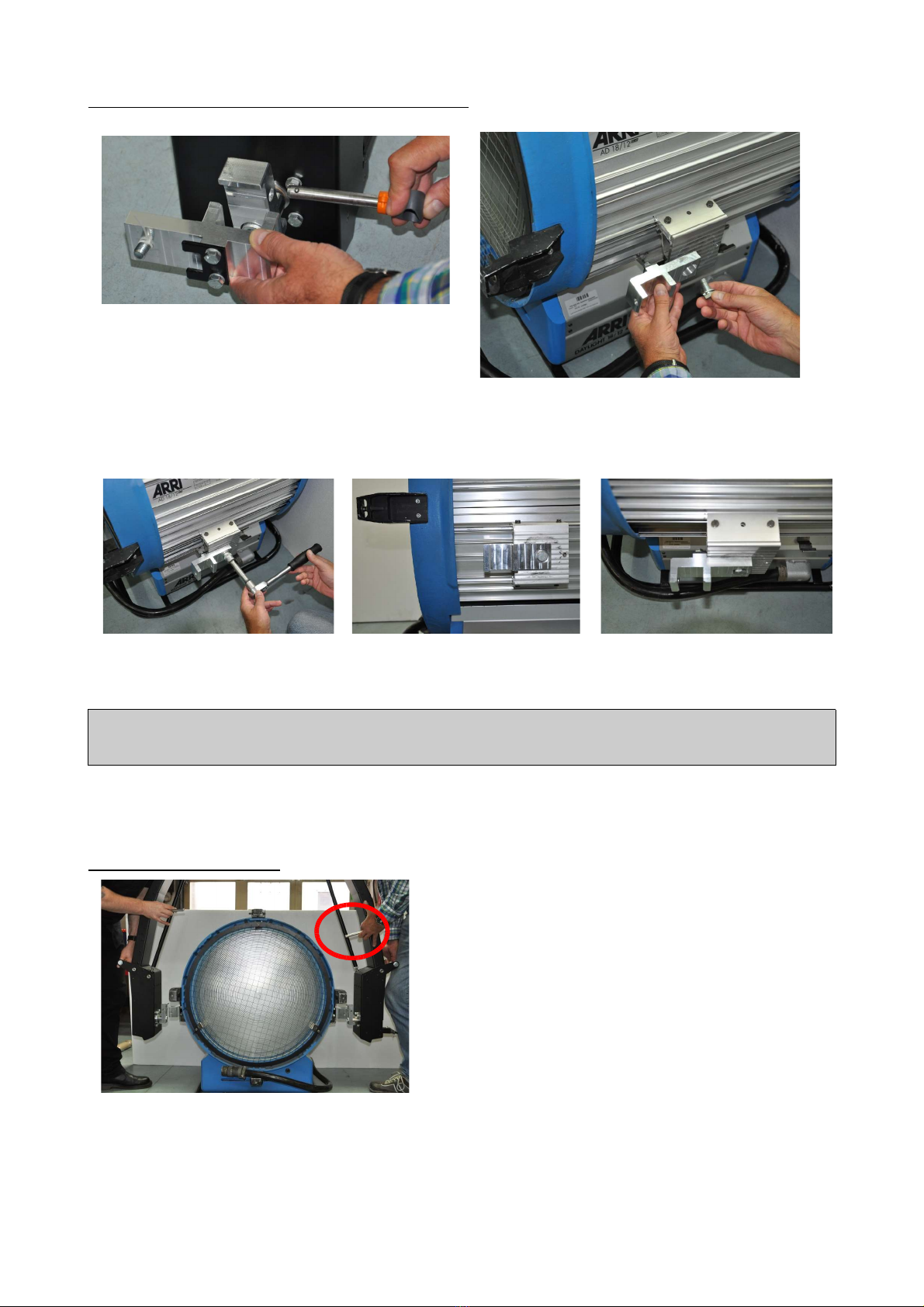

Readjustment of motoryoke axis........................................................................................ 44

Factory presettin s............................................................................................................. 45

Maintenance....................................................................................................................... 46

Error messa es.................................................................................................................. 48

Malfunctions....................................................................................................................... 49

Warranty............................................................................................................................. 50

Further information............................................................................................................. 50

EC Declaration of Conformity............................................................................................. 51

FCC Declaration of Conformity.......................................................................................... 52

Motoryoke MB D1 V4.56 Rev 1.06 3