Inhaltsverzeichnis

Introduction........................................................................................................................... 4

Appropriate use.................................................................................................................... 4

The Licht-Technik otoryoke YipMan.................................................................................. 4

Safety- and operating instructions........................................................................................ 6

Quick start guide.................................................................................................................. 9

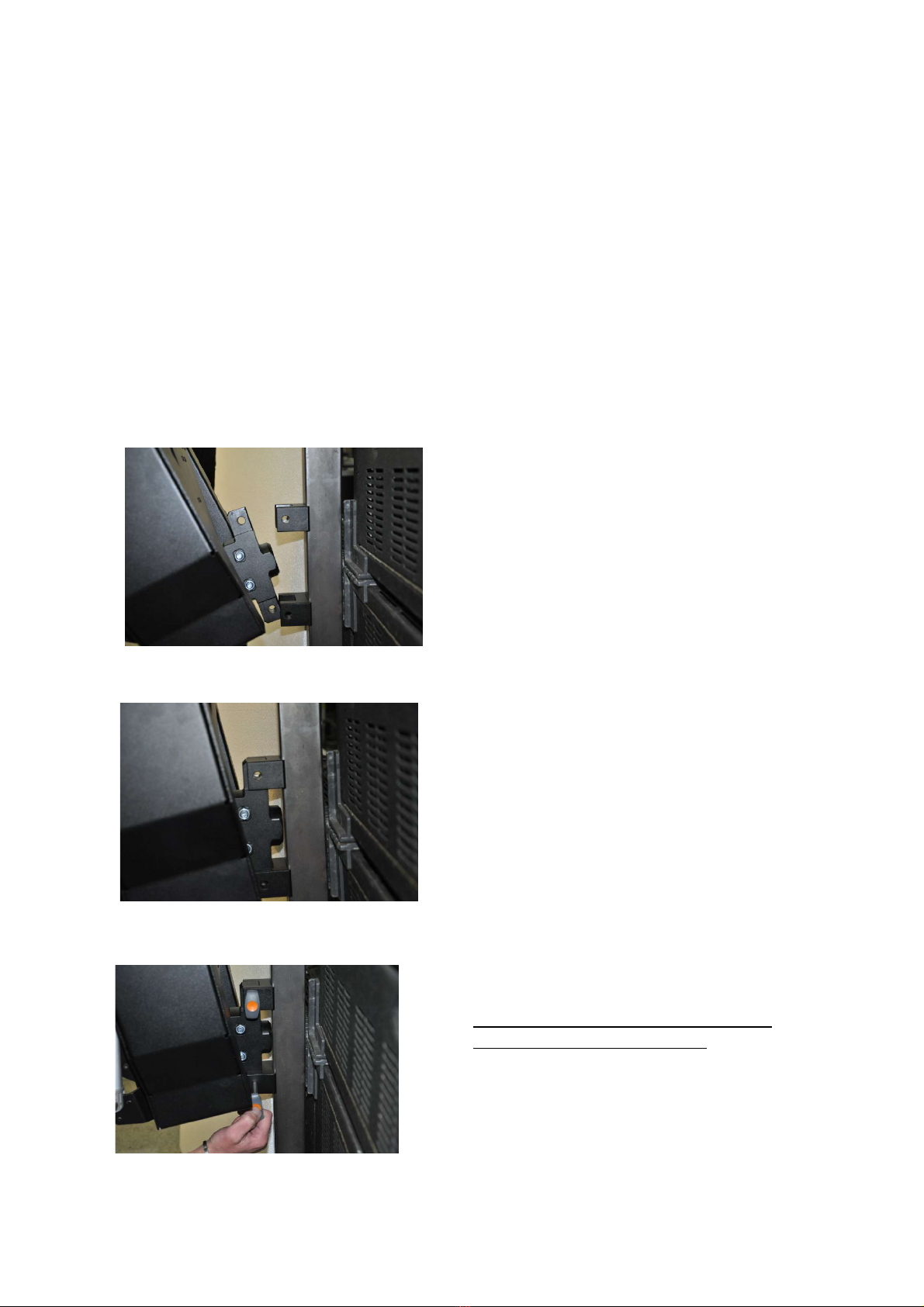

Asse bling the oving device........................................................................................... 10

Identification....................................................................................................................... 11

The DMX-standard in lighting............................................................................................. 11

Cabling............................................................................................................................... 12

Getting started.................................................................................................................... 14

PAN – axis oving range................................................................................................... 15

User interface..................................................................................................................... 18

Display lighting ON/OFF..................................................................................................... 18

DMX channels otoryoke.................................................................................................. 19

P01 DMX-Address otoryoke............................................................................................ 20

P02 Rotation unit ON/OFF................................................................................................. 21

P05 PAN-axis iddle position............................................................................................ 22

P06 TILT-axis 0-degree position......................................................................................... 23

P11 PAN-axis oving range............................................................................................... 24

P12 TILT-down (negative) oving range............................................................................ 25

P13 TILT-up (positive) oving range.................................................................................. 26

P14 Focus / rotation 0%-value........................................................................................... 27

P15 Focus/rotation unit 100%-value adjust ent................................................................ 28

P27 Speed PAN/TILT setup............................................................................................... 29

P30 Displaying the DMX-value........................................................................................... 30

P32 Selecting the user language....................................................................................... 31

P33 PAN-axis loading position........................................................................................... 32

P34 TILT-axis loading position............................................................................................ 33

P35 rotation-axis loading position...................................................................................... 34

P36 Interchanging PAN oving direction........................................................................... 35

P37 Interchanging TILT oving direction........................................................................... 36

P38 Interchanging rotation oving direction...................................................................... 37

Technical data.................................................................................................................... 38

Werkseinstellungen............................................................................................................ 39

Maintenance....................................................................................................................... 40

Error essages.................................................................................................................. 42

Malfunctions....................................................................................................................... 43

Warranty............................................................................................................................. 44

Further infor ation............................................................................................................. 44

EC Declaration of Confor ity............................................................................................. 45

Motoryoke YipMan1 V4.58 Rev 1.00 3