6/18 Operation Manual PREFAB EASY SCREED, revision 2: 29-6-2016

4. Safety

Explanation of the used safety symbols:

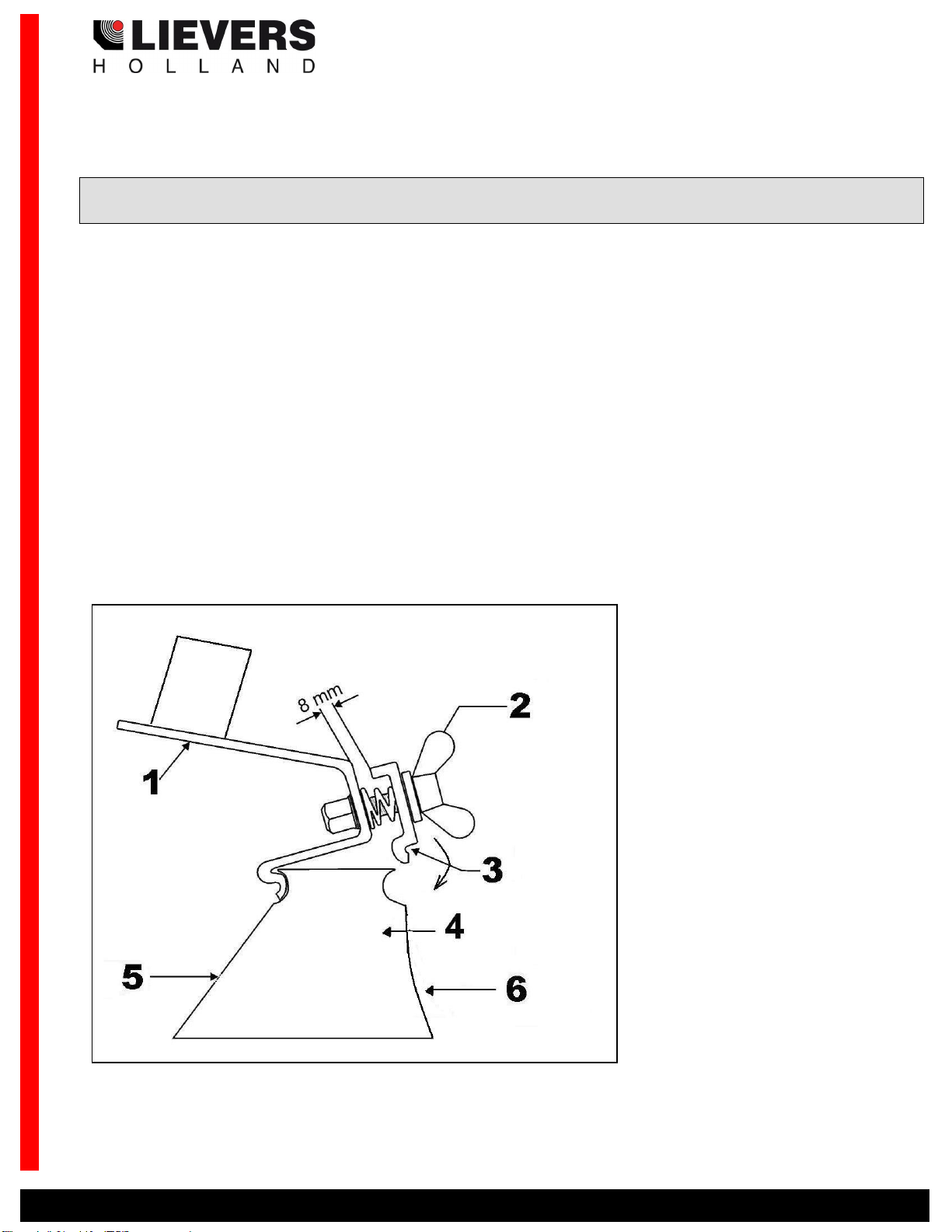

Fig. 3: Safety symbols Prefab Easy Screed

ENSURE,THAT ALL SYMBOLS ON THE MACHINE,CAN ALWAYS BE CLEARLY READ.

4.1 Safety aspects

The following safety aspects apply to the machine:

Safety symbols are present on the Prefab Easy Screed

4.2 Safety precautions

The Lievers bullfloats have been developed and tested in accordance with the strict international safety standards.

Before operating these machines, make sure to have read this manual carefully. If you have any questions , do not

hesitate to contact the supplier.

Ensure that you are qualified (familiar with the contents of this manual), to operate and carry out light

maintenance work to the machine.

Wear safety shoes with extra protection (steel caps and anti-slip soles).

Wear a safety helmet and hearing protection.

Wear safety glasses, working gloves which do not conduct electricity and protective clothing.

Ensure that all symbols on the machine, can always be clearly read.

Be careful when lifting and carrying the bullfloat. Do not bend forwards when picking up the machine, but bend

your knees.

When cleaning the machine, ensure that no water or cleaning detergents get into the motorhousing.

When the machine is not being used for longer periods of time, then it must be stored in a dry and clean area.

Regular maintenance of the machine promotes safe operation.

1. Read the instruction manual before using the

machine.

2. Safety glasses, safety helmet and ear

protection compulsory.

3. Working gloves compulsory.

4. Safety shoes with extra protection

compulsory.

5. Before opening remove the plug.

6. Dangerous electric voltage

7. Be careful.