CONTENTS

MOTORCYCLE SAFE RIDING

Safe Riding Rules .............................................................................. 1

Protective Cloths .............................................................................. 1

Refitting .............................................................................................. 1

Loading .............................................................................................. 1

Accessories ........................................................................................ 1

GENERAL INFORMATION

Parts Location ................................................................................... 2

VIN Record ......................................................................................... 3

Fuel and Engine Oil (EP) ................................................................. 3

CONTROLLING PARTS

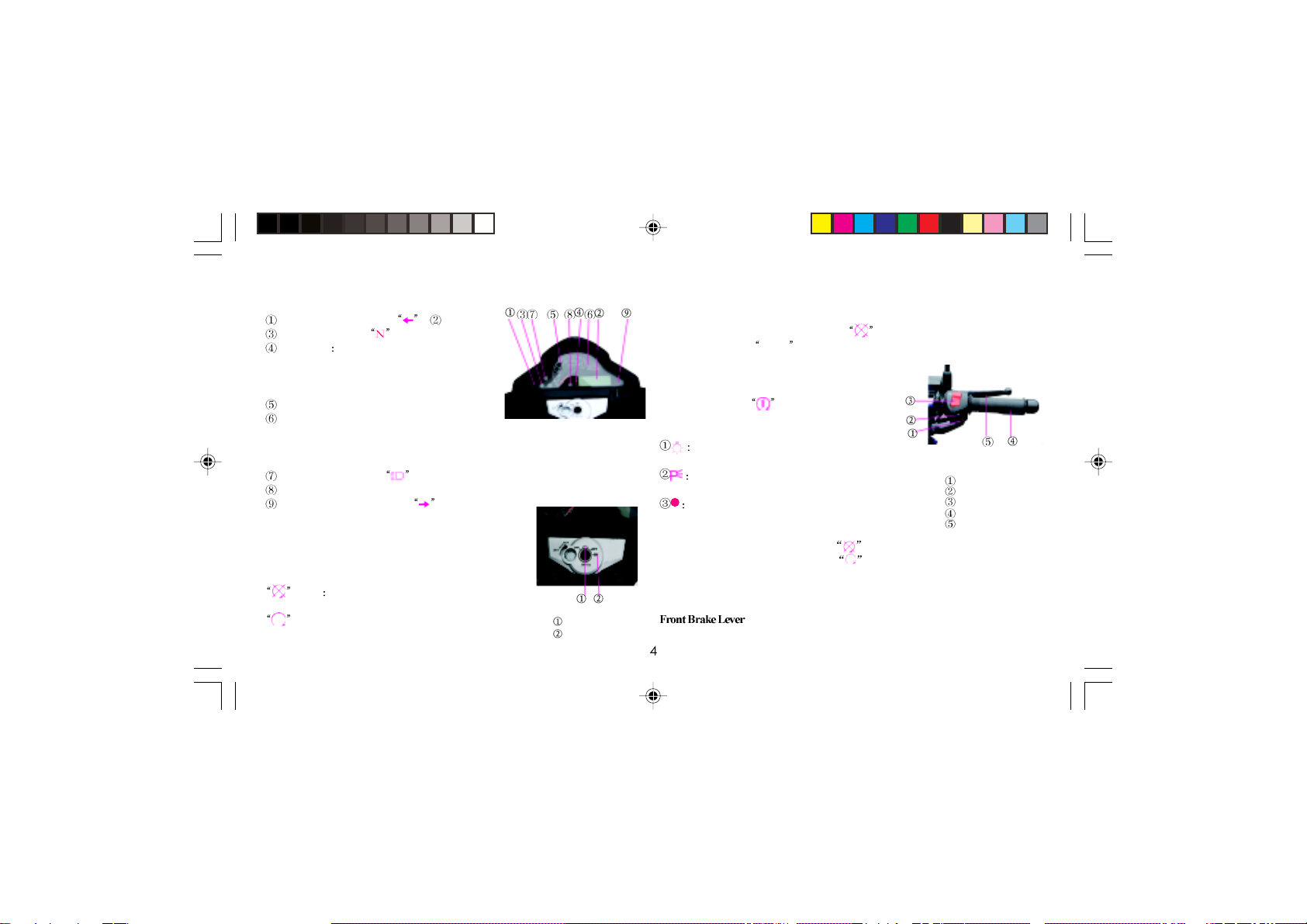

Meter and Indicators ......................................................................... 4

Ignition Switch and Steering Lock ................................................. 4

Right Handlebar Controls ................................................................ 4

Left Handlebar Controls ................................................................... 5

Choke Lever ....................................................................................... 5

Refueling and Cap ............................................................................. 5

Fuel Cock............................................................................................ 5

Gearshift Pedal .................................................................................. 6

Rear Brake Pedal ................................................................................ 6

Rear Shock Absorber ........................................................................ 6

Stands ................................................................................................. 6

Principle of Fuel Evaporating Systerm (EP) .................................. 7

OPERATION GUIDE

Pre-ride Inspection............................................................................ 7

Starting the Engine ........................................................................... 7

Breaking-in ........................................................................................ 8

Riding ................................................................................................. 8

Braking and Parking ......................................................................... 8

MAINTENANCE

Tool Kit ............................................................................................... 9

Maintenance Schedule ...................................................................... 9

Engine Oil (EP) ................................................................................... 10

Coolant ............................................................................................... 10

Servicing of Cooling System ............................................................ 11

Clear away Carbon Deposit (EP) ....................................................... 11

Spark Plug (EP)................................................................................. 11

Air Cleaner (EP) ................................................................................ 11

Valve Clearance .................................................................................. 12

Exhaust Muffler .................................................................................. 12

3-Way Catalytic Converter (EP) ........................................................ 12

Fuel Filter ........................................................................................... 13

Operation of Throttle ........................................................................ 13

Idle Speed of Carburetor (EP) ......................................................... 13

Check Leaks along Air Supply (EP)............................................... 13

Clutch ................................................................................................. 13

Drive Chain ........................................................................................ 13

Front Brake ......................................................................................... 14

Rear Brake ........................................................................................... 15

How to Check and Replace Brake Pad ............................................ 15

Front/Rear Shock Absorber and Suspension ................................. 15

Tyre ...................................................................................................... 15

Front Wheel ....................................................................................... 16

Rear Wheel ......................................................................................... 16

Fuse ..................................................................................................... 16

Battery (EP) ....................................................................................... 16

TROUBLESHOOTING AND STORAGE

Troubleshooting................................................................................ 17

Cleaning and Storage ........................................................................ 17

Removal from Storage ........................................................................ 17

Anti-fall-over Device (Optional) .................................................... 17

Motorcycle Alarm (Optional) .......................................................... 18

ELECTRIC DIAGRAM ......................................................................... 19

SPECIFICATIONS .................................................................................. 20

LF 150-10B(ENGLISH)A.p65 2012-4-23, 9:333