BRAKE AND STOPPING OF THE MOTORCYCLE

When need stop ,should close the throttle ,grasp at the handle of the clutch letting go

the clutch ,meanwhile evenly use the front and rear brake till completely stop driving.

The motorcycle moves to the blank gear , the switch button of the engine stalling

rotate to off so that make the engine rotate ,make the switch of the fuel rotate to

off ,stand the bracket a nd make the motorcycle stop evenly .

Turn the ignition switch to off ,take out the key of the ignition switch

Lock the lock of the head of the motorcycle, take out the key of the ignition switch

REMARKS:

Slow down the stopping vehicle while must use the front and rear of the brake in

order to prevent from side sliding or side turning over ,but independently operate the

front and rear brake which will give rise to the swift abrasion and damage of the

brake.

Overspeed or in the wet and sliding surface of the road , should avoid braking

urgently ,otherwise , it would cause the danger of the accidents.

When need slow down ,in the first place ,should reduce thethrottle ,gradually use

the front and rear brake , which may come to deceleration and stopping .when need

brake urgently ,first should reset the throttle , and then using decisively the front and

rear brake .

On the damp surface of the road where goingon the brake is quite difficult: avoid

braking urgently and stopping movement .owing to this easily cause the turnover of

the motorcycle .when need stop on the damp surface of the road ,should slowly brake

so that the vehicle can evenly stop .

When closing near to the zigzagor turning , should close thethrottle and use the

brake slowing down .otherwise , whichhas difficulty in controlling that give rise to

side sliding and turning over .

On the wet or soft surface of theroad ,should take note of operation evenly .other-

wise ,it would be out of control.

When pass by the other vehicles stopping onthe roadside , must be careful:owing

to inside the drivers perhaps do not see you and open the door of the motorcycle ,

shelter your advance direction.

The road rail on the road ,steel boardon the building place and channel which are

damp so slip ,when the vehiclespass by ,should slow down aheadof time and take

note of keeping the vertical body ,otherwise may be cause the side sliding of thetyre

and out of control.

The grinding slice ofthe brake may be wet when the motorcycle cleaned. before

starting,should check all controlling systems .

No over-loading on the motorcycle,above all no hanging anygoods,otherwise it

would make the motorcycle lose balance.

INSPECTING AND REPLACEMENT OF THE LUBRICATION

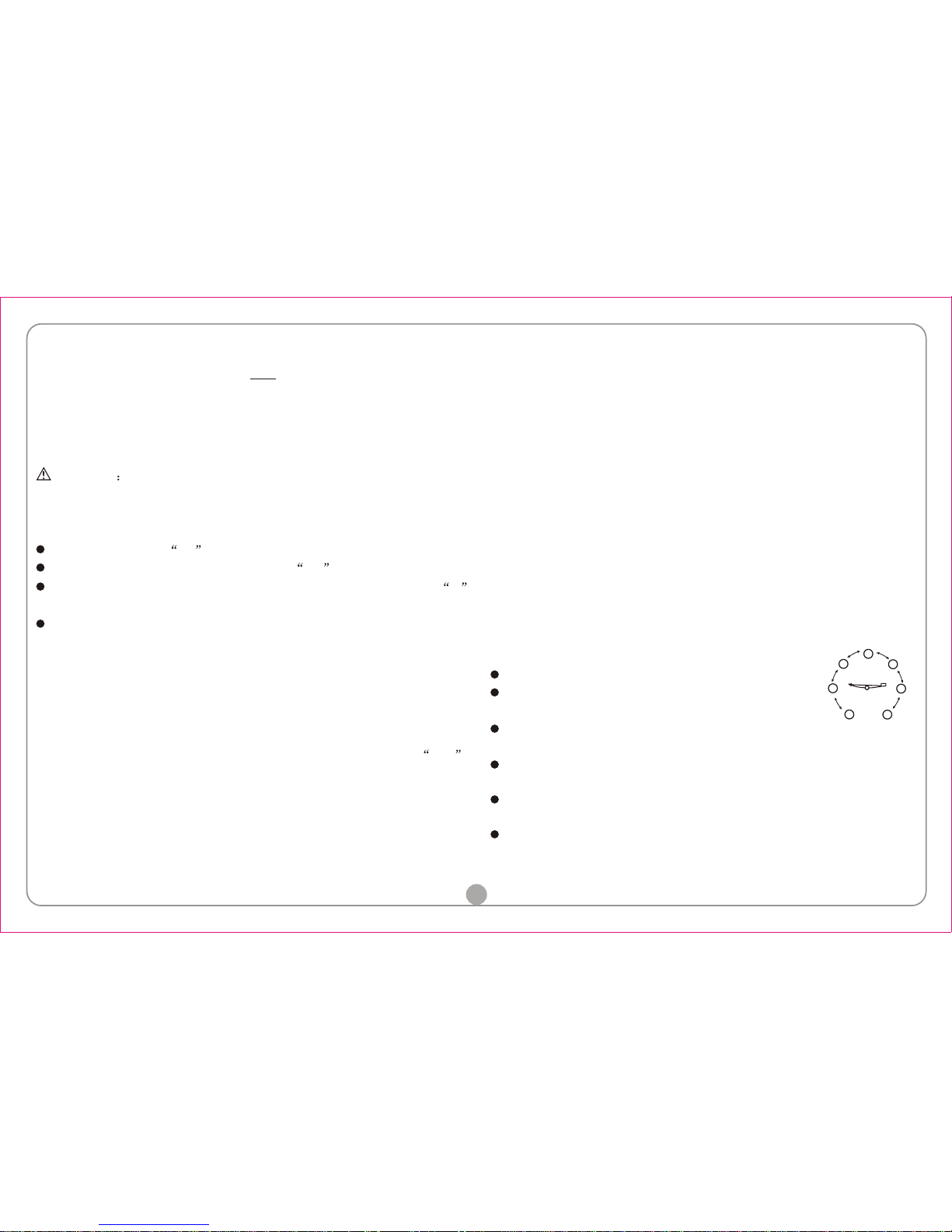

(INSPECTING OF THE FUEL LEVEL) (FIG17)

before driving,check the level of the lubrication .

the rear ofthe box ofthe camshaft hasno the rulerof the

engine oil ,measuring the level ofthe lubrication ,which in

between the two scales indicated up and down.

*lay the motorcycle down on the ground ,support the bracket

,take out the ruler of the engine oil ,aftercleaning,insert the

ruler, and then take outand observe .

*add to the engine oil ofthe gasoline of 15w/40-SE up toupper scale ,no filling up

*resettle the ruler of the engine oil ,inspect whetherleaks oil

REMARKS :

WHEN THE ENGINE OILIS NOT ENOUGH ,DRIVING MAY CAUSE EQUIP-

MENTS AND PARTS DAMAGED .

(REPLACEMENT OF THE LUBRICATION )

*lay the motorcycle down on the ground ,support the side stand ,startthe engine and

let it idle a fewminutes ,and then unscrew the ruler of the engine oilof the engine

and the bottom of the plug of thetaking oil,tread and press the kick rod manytimes

,thoroughly give off the left oil .

*check the gasket of the plugof the taking oil whether is good ,if damaged ,should

change ,and reset the plug of thefuel and screw tightly.

*inject the engine oilof the dictating quantity,start the engine ,afterrotate many

minutes with idle speed ,andthen stopping ,check the level of the fuel again ,but

8

Upper leve mark

Lower leve mark

Fig.17

Oil filler cap/Dipstick