Page 10 253273 R3

Section 3 Periodic Maintenance

Periodic Maintenance

For proper operation and an extended service life, your

Lift Tek Mast should be inspected and serviced regularly

as part of your normal lift truck maintenance schedule accord-

ing to the following outlines and ANSI B56.1 procedures.

The recommended intervals are for masts operating under

normal conditions. If the mast is operating in severe conditions

or corrosive atmospheres, the inspections should be per-

formed more frequently.

WARNING: Never work on the mast with a load

on the forks or attachment, in the raised position

without supports or while anyone is near the lift

truck control handles per ANSI B56.1

Daily Inspection

Perform the following at the beginning of each work shift:

1. Extend the carriage a few inches off the ground and make

sure the chains are under equal tension. Refer to Section

5.6-3 for chain adjustment.

2. Extend the mast to its fullest height to make sure the mast rails

and carriage extend freely without binding.

3. While the mast is extended, inspect the upright rails for

proper lubrication. Refer to Section 2.4-3 for rail

lubrication.

4. Make sure the internal reeving hoses (if equipped) travel

evenly in the hose guides. Adjust the hose ends if re-

quired. Tighten the fittings making sure they do not twist.

5.In applications with high humidity or condensation, chain

lubrication as described under Item 1 of the 100 hour

inspection may be needed more frequently to reduce the

risk of corrosion.

100 Hour Inspection

After each 100 hours of lift truck operation, and in addition to

the daily inspection:

1. Inspect and lubricate the full length of the chains with SAE

40 wt. oil or equivalent.

CAUTION: The chains must be coated with a film of lubricant

at all times.

500 Hour Inspection

After each 500 hours of lift truck operation, and in addition to

the Daily and 100 Hour Inspection:

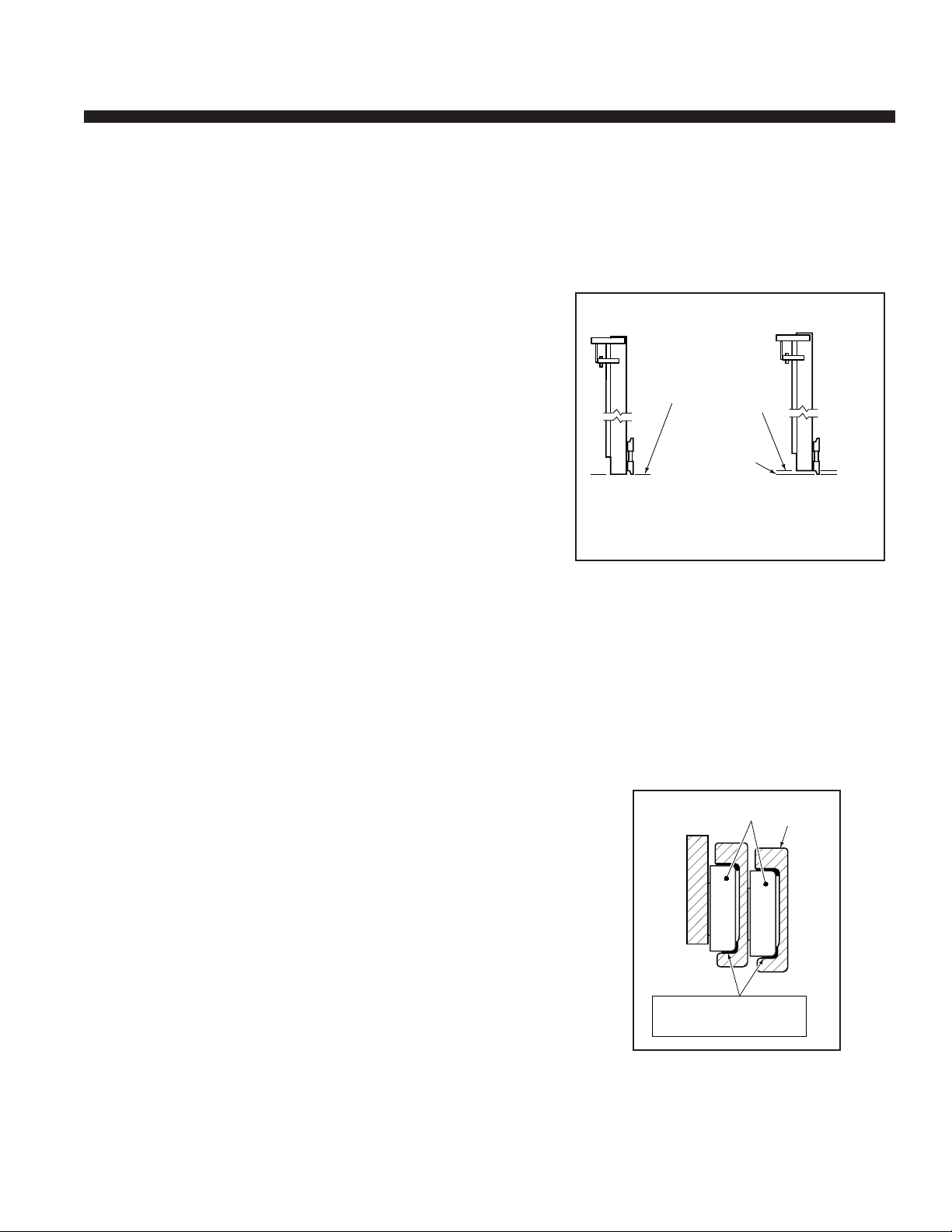

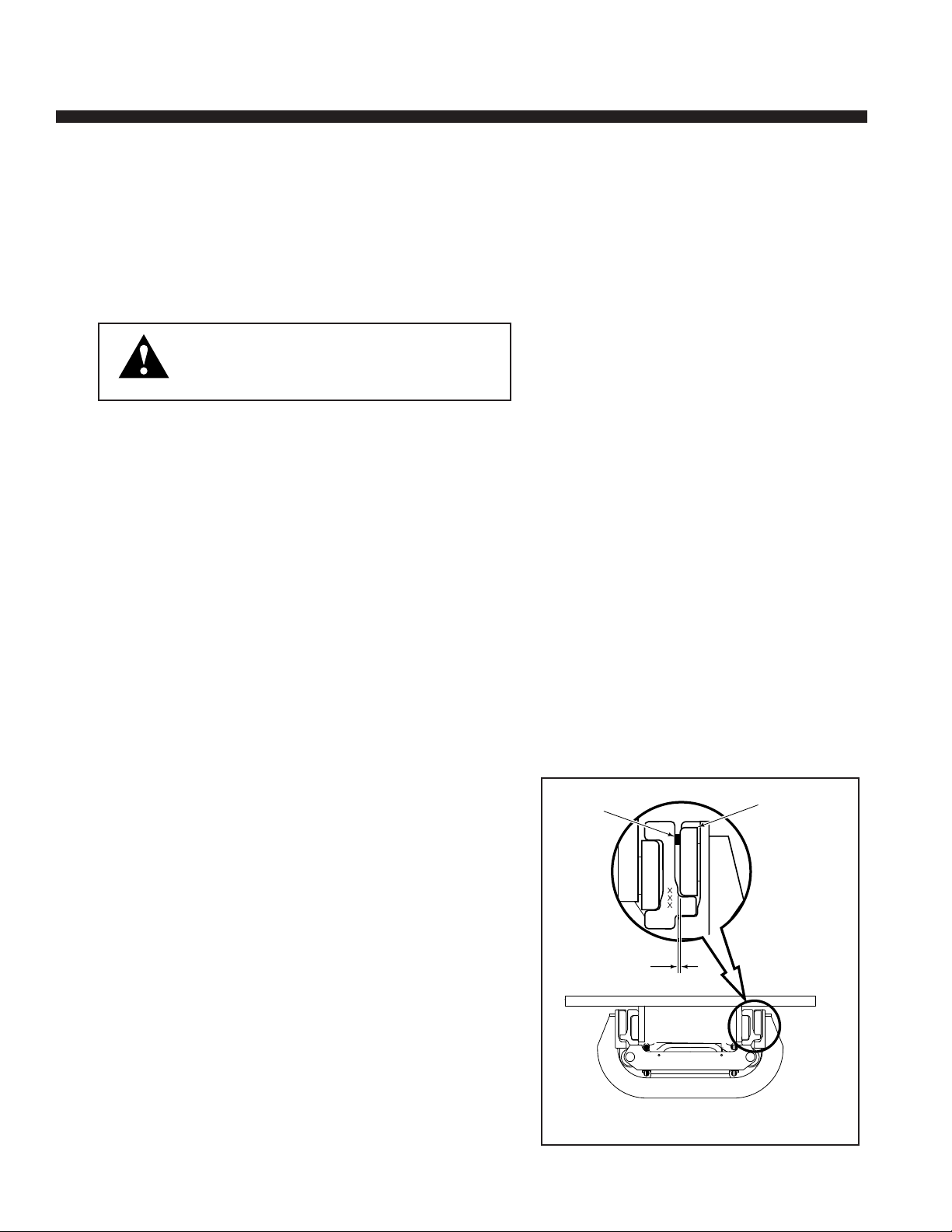

1. Each pair of load rollers on the uprights and carriage

should be shimmed so that a total side to side clearance

no greater than 1/16 in. (1.5 mm) occurs at the tightest

point throughout the travel of the member. Pry between

the upright and load roller so that the opposite load roller

is tight against the upright. Measure the clearance for the

pair of rollers at XXX shown. See Figure 8.

2. Check the chains for wear and stretch. Refer to Section

5.6-1 for complete chain inspection.

3.1

3.1-1

MA2705.eps

Pry Here Load Rollers

.06 in.

(1.5 mm)

MAX.

Figure 8. Load Roller Clearances.