Lightway PV Modules, Installation Manual, Page 3/36

www.lightwaysolar.com

module should be multiplied by of 1.25 when determining component voltage ratings, conductor current ratings,

fuse sizes, and size of controls connected to the PV output.

⊙The safety factor of 1.25 for the minimum voltage rating of the components can be modified during the design

of a system according to the minimum temperature of the location of the installation and the temperature

coefficient for Voc and Isc can be adjusted based on maximal temperature, irradiance and orientation of the

module. To this end a full simulation for the specific location is required using long term weather data.

⊙Module application: Class A (modules rated for use in this application class maybe used in systems operating at

greater than 50V DC or 240W, there general contact access is anticipated, Modules qualified for safety through this

part of IEC61730 and IEC61730-2 and within this application class are considered to meet the requirements for

safety Class Ⅱ.)

⊙The recommended stand-off height is about 115mm, if other mounting means are employed, this may affect

the Listing for Fire Class Ratings. When installed on a roof, the module shall be mounted over an fire-resistant roof

covering rated for the application, the mounting design may have an impact on the fire resistance.

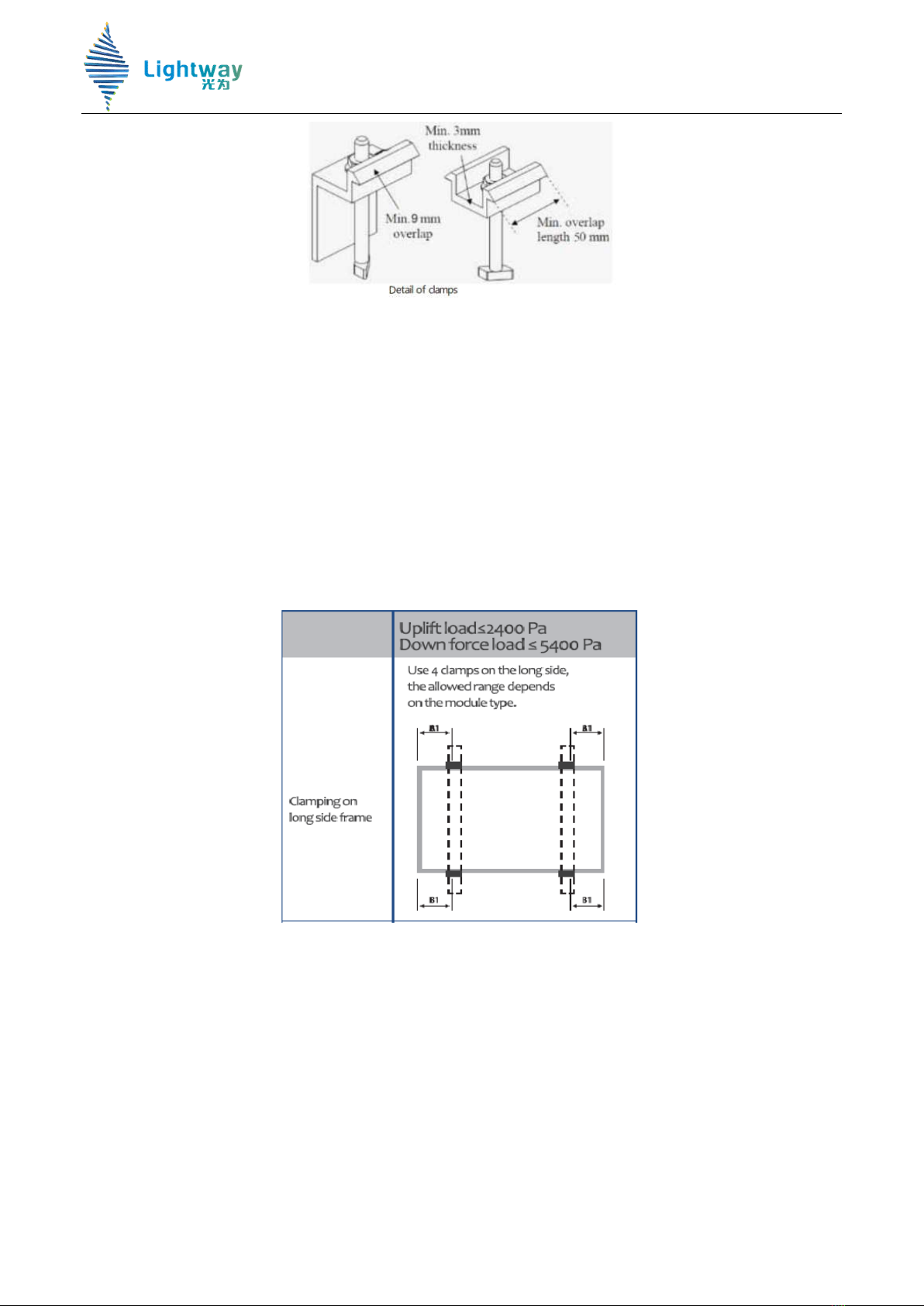

⊙Ensure that the installation method and supporting system of modules is strong enough to make the modules to

able to withstand all the load conditions. The Installer must provide the guarantee. The installation supporting

system must be tested by the third-party organization with the analysis ability of Static Mechanical, according to

the local national or international standards such as DIN1055 or equivalent standards.

⊙The Modules mounting structure must be made of durable, corrosion-resistant and UV-resistant material.

⊙Modules must be securely attached to the mounting structure.

⊙In regions with heavy snowfall in winter, select the height of the mounting system. So that the lowest edge of

the Modules is not covered by snow for any length of time. In addition, ensure that the lowest portion of the

Modules is placed high enough so that it is not shaded by plants or trees or damaged by flying sand.

⊙In case of installed on metal sheet roof, flush mounting is recommended. In case of installed on concrete roof,

the module could be tilted and a minimum of 10 degrees tilt angle should be follow for cleaning.

⊙Do not attempt to drill holes in the glass surface and the frames of the Modules .Before installing Modules on a

roof, ensure that the roof construction is suitable. In addition, any roof penetration required to mount the

Modules must be properly sealed to prevent leaks.

⊙Always keep the back sheet of the module free from foreign objects or structural elements, which could come

into contact with the module, especially when the module is under mechanical load.

⊙Please wear special labor protection gloves to avoid leaving fingerprints and perspiration stains and other dirt

on glasses. Regularly replace the dirty gloves in time.

⊙For module,external factors may lead the result such as thermal expansion and contraction, the same matrix is

recommended to reserve a certain distance between any two modules,at least 20mm.

⊙There are three colors in Lightway modules, light blue, blue and dark blue. In order to have a beautiful visual

effect, please install modules with the neighboring color. Light blue and dark blue should not be installed together.

⊙Please keep the connectors in tough while installing module. The cable should keep a certain length to ensure

that the both ends of cable have no stress.

When mounting modules in snow⊙-prone or high-wind environments, special care should be taken to mount the

modules in a manner that provides sufficient design while meeting local code requirements.

Product identification

Each module has two labels providing the following information:

Nameplate: describes the product type; rated power, rated current, rated voltage, open circuit voltage, short

circuit current, all as measured under standard test conditions; dimension etc. The maximum system voltage is