iv LY Installation and Maintenance for LY 1001, LY 2001 and LY 3001 LMAIM1501

7 Maintenance 7-1

7.1 Lubrication 7-1

7.1.1 Lubrication Inspection 7-1

7.1.2 Factor Lubricant 7-1

7.2 Minimum Lubricant Qualities Required 7-1

7.3 Disassembl and Reassembl 7-2

7.3.1 LY 1001 Disassembl 7-2

7.3.2 LY 1001 Reassembl 7-3

7.3.3 LY 2001/3001 Disassembl 7-5

7.3.4 LY 2001/3001 Reassembl 7-7

7.4 Troubleshooting 7-9

8 Parts Lists 8-1

9 How to Order Parts 9-1

10 Regulatory Information 10-1

Figures

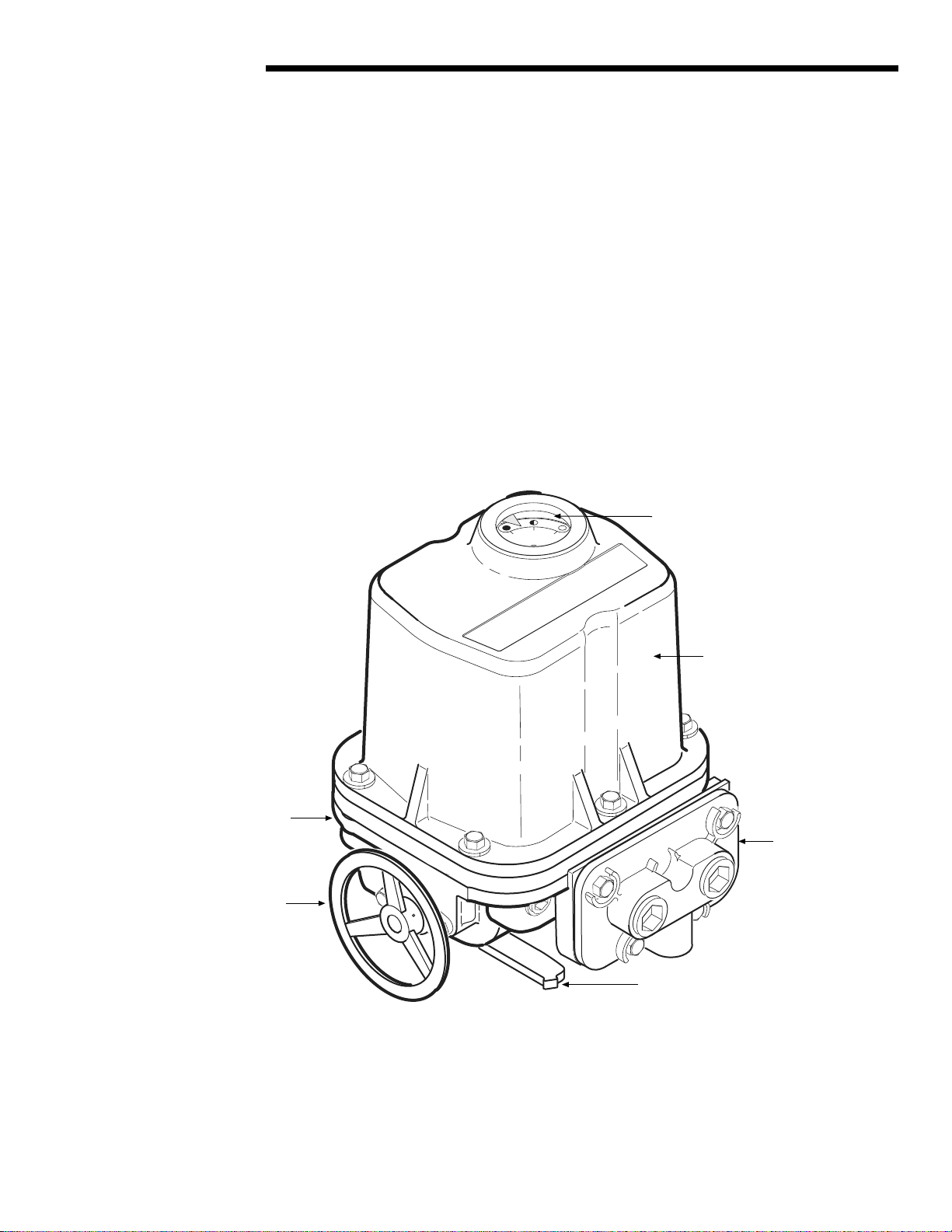

Figure 2.1 – LY Actuator 2-1

Figure 3.1 – LY Nameplate 3-1

Figure 5.1 – Torque Nut and Retaining Drive Ring Removal from an LY 1001 5-1

Figure 5.2 – LY Ke wa Locations 5-2

Figure 5.3 – LY 1001, 2001, and 3001 Torque Drive Nut Orientation 5-3

Figure 5.4 – Removing Control Cover and Conduit Pipe Plugs 5-4

Figure 5.5 – Grounding Lug Location 5-5

Figure 5.6 – Reversing Torque Switch Wiring 5-7

Figure 5.7 – Limit Switch Setting Nut 5-8

Figure 5.8 – Setting CLOSE Limit Cam 5-9

Figure 5.9 – Setting OPEN Limit Cam 5-10

Figure 5.10 – Mechanical Stop Set Screw Adjusted to Torque Drive Nut

Contact Point on LY 1001 5-11

Figure 5.11 – Mechanical Stop Screw Adjustment on LY 2001 and 3001 5-12

Figure 5.12 – Aligning MDPI (Mechanical Dial Position Indicator) 5-13

Figure 5.13 – Potentiometer Calibration Components 5-14

Figure 6.1 – Standard Actuator/Three-Phase 6-2

Figure 6.2 – Three-Phase with Control Package 6-3

Figure 6.3 – Standard Actuator/Single-Phase 6-5

Figure 6.4 – Single-Phase with Control Package 6-6

Figure 6.5 – LY 1001 Cover and Associated Parts 6-7

Figure 6.6 – LY 1001 Top Plate and Associated Parts 6-9

Figure 6.7 – LY 1001 Housing and Associated Parts 6-10

Figure 6.8 – LY 2001/3001 Cover and Associated Parts 6-11

Flow Control Division

Limitorque Actuation S stems