Triminator BuckMaster Series User manual

®

buckmaster Series

OWNER'SMANUALv1

CONTENTS

INTRODUCTION ............................................................2

SAFETY MESSAGES....................................................... 2

BUCKER SAFETY............................................................3

IMPORTANT SAFETY INFORMATION ......................... 3

SAFETY LABEL LOCATIONS ......................................... 4

SETUP AND ASSEMBLY ................................................5

COMPONENTS............................................................... 6

OPERATION.................................................................... 8

CONTROLS .....................................................................9

STARTING THE BUCKER .............................................10

BUCKING TIPS .............................................................11

MAINTENANCE SAFETY .............................................12

DISASSEMBLE FOR CLEANING AND SERVICE........13

CLEANING AND REASSEMBLY ..................................15

TAKING CARE OF UNEXPECTED PROBLEMS..........17

CUSTOMER SERVICE ..................................................18

LIMITED WARRANTY ..................................................19

EXCLUSIONS FROM WARRANTY COVERAGE.........20

INTRODUCTION

Congratulations on your selection of the Triminator commercial bucker. We want to

help you to get the best results from your new bucker and to operate it safely. This man-

ual contains the information on how to do that; please read it carefully before you set

up and use your bucker. This manual reects the instructions for both the BuckMaster

and BuckMaster Pro machines.

We suggest you read the LIMITED WARRANTY (page 19) to fully understand coverage

and your responsibilities of ownership. Keep this owner’s manual handy, so you can

refer to it at any time. This owner’s manual is considered a permanent part of the bucker

and should remain with the bucker if resold. The information and specications includ-

ed in this publication are those that were in eect at the time of approval for printing.

Mosman Machinery Company, Inc. reserves the right, however, to discontinue or change

specications or design at any time without notice and without incurring any obligation

whatever. No part of this publication may be reproduced without written permission.

SAFETY MESSAGES

Your safety and the safety of others are very important. We have provided important

safety messages in this manual and on the Triminator. This information alerts you to

potential hazards that could hurt you or others. Please read these messages carefully. Of

course, it is not practical or possible to warn you about all the hazards associated with

operating or maintaining a bucker. You must use your own good judgment.

You will nd important safety information in a variety of forms:

Safety Labels - located on the bucker.

Instructions - how to use this bucker correctly and safely.

Safety Messages - preceded by a safety alert.

A symbol and one of two signal words: DANGER, CAUTION. These signal words mean:

Each message tells you what the hazard is, what can happen, and what you can do to

avoid injury.

Damage Prevention Messages - You will also see other important messages that are

preceded by the word NOTICE. This word means:

2

DANGER

!CAUTION

You WILL be KILLED or SERIOUSLY

HURT if you don’t follow instructions.

You CAN be KILLED or SERIOUSLY

HURT if you don’t follow instructions.

NOTICE Your bucker or other property can be dam-

aged if you don’t follow instructions.

BUCKER SAFETY

IMPORTANT SAFETY INFORMATION

Triminator commercial buckers are designed to remove owers from stems on a variety

of herbal material. Other uses could result in injury to the operator or damage to the

bucker and other property. Injuries and property damage from buckers can be prevent-

ed by following all instructions in this manual and on the bucker. The most common

hazards are discussed below, along with the best way to protect yourself and others.

Avoid Rotating Rubber Rollers

The Triminator’s rubber rollers can cause serious damage, cuts and even amputate

ngers or hands. Keep hands, arms, and body away from the rubber rollers whenever

the drum drive motor is running. Keep hair, clothing, and jewelry away from the rollers.

If you need to work around the bucker to clear or clean plant material for any reason,

always shut o the electric motor and disconnect the bucker’s power cord from the AC

outlet. Never put your hand in contact with the rubber rollers while the machine is run-

ning; serious personal injury could result.

Clear Operation Area

Before operating the bucker, carefully inspect the surrounding area and remove all obvi-

ous hazards that could cause you to trip, slip, or fall into the bucker.

Keep Guards and Shields in Place

Guards and shields are designed to protect you from touching moving components. For

your safety and the safety of others, keep all shields in place when the bucker is run-

ning.

Turn Electric Motor O When Not Operating the Bucker

If you need to leave the bucker for any reason, always turn the electric motor o.

Operate on Flat Surface

To avoid overturning, only operate the bucker on at surfaces. Control the bucker care-

fully when transporting it across uneven ground or slopes. Do not push the bucker down

or across steep slopes: the bucker could overturn, causing injury to the operator or

bystanders.

Operator Responsibility

Know how to stop the bucker quickly in case of emergency. Understand the use of all

bucker controls. Never permit anyone to operate the bucker without proper instruction.

Do not let children operate the bucker.

3

SAFETY LABEL LOCATIONS

43

!CAUTION

Read user guide

before operating

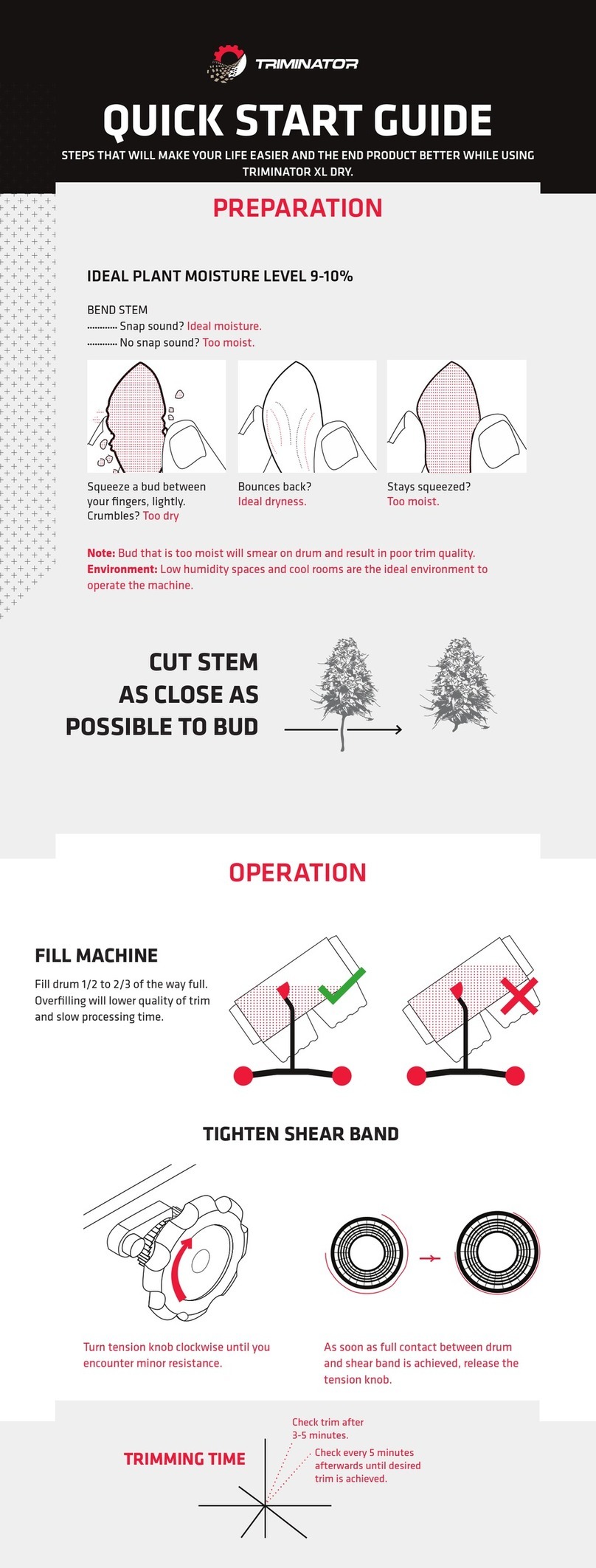

SETUP AND ASSEMBLY

5

UNPACKING and INSPECTION

Triminator BuckMaster comes in shipping boxes disassembled. Upon receipt

please check the boxes for damage and mark any damage on the shipping BOL and

follow the shipper’s instructions.

1. To begin, disassemble the shipping boxes. Make note of any damage, which is

identied on either the machine parts or the shipping crate. Notify the shipper,

your dealer and MMC immediately, should damage be identied.

2. Remove the components from the packaging and place them on a at and level

surface.

ASSEMBLY:

Required tools

Standard hex wrench set

Personnel

Two people are recommended to help with the assembly of the BuckMaster Ma-

chines. It can be completed with one person, however assembly may take longer

and be more dicult.

Instructions

Follow the video instructions at the link below:

BUCKMASTER SERIES

http://bit.ly/buckmasterproassembly

65

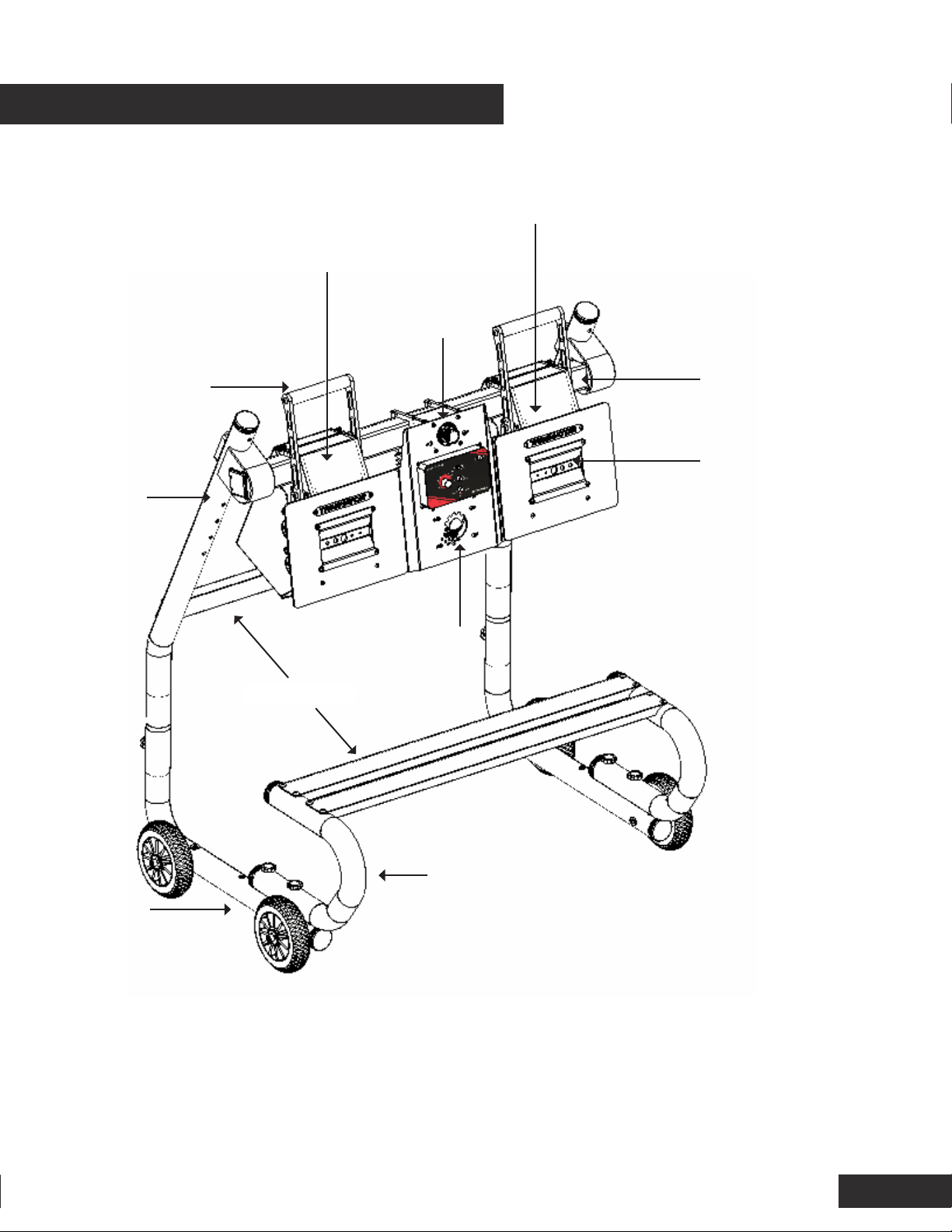

ROLLER ASSEMBLY

Contains rubber rollers, roller

guard, and bucking plates

ROLLER HANDLE

Releases tension

on rubber roller

wheels

COMPONENTS

MOTOR ASSEMBLY and CONTROLS

Contains motor, speed controller, power

and on/o switches

CROSS BARS

MATERIAL HOLDER

Used for ergonomic placement

of material collection bins

ADDITIONAL ROLLER ASSEMBLY

(PRO MODELS)

Contains rubber rollers, roller guard,

and bucking plates. Available only on

Pro models or as a Pro upgrade

BUCKING PLATE

Change from wet

to dry bucking by

changing this plate

UPPER

STAND LEG

LOWER

STAND

LEG

CROSS TUBE

EMERGENCY STOP

BEFORE OPERATION

Read and understand this manual. Know what the controls do and how to operate

them. Familiarize yourself with the bucker and its operation before you begin using

it. Know how to quickly shut o the machine in case of an emergency.

Your safety is your responsibility.

IS YOUR BUCKER READY FOR OPERATION?

For your safety, and to maximize the service life of your equipment, it is very im-

portant to take a few moments each time before you operate the bucker to check

its condition. Be sure to take care of any problem you nd before you operate the

bucker.

Improperly maintaining this bucker, or failing to correct a problem before opera-

tion, could cause a malfunction which could cause you to be seriously injured.

Always perform a pre-operation inspection before each operation, and correct any

problem.

Before beginning your pre-operation checks, be sure the bucker is on a level sur-

face, the motor timer switch is in the OFF position, and all power cords are un-

plugged.

Check the General Condition of the Bucker

Clean the rubber rollers, bucking plates, and tension system. Look for signs of

damage.

Check each control for proper operation.

Check parts for wear. Replace if necessary.

Check that all nuts, bolts, and clamps are tightened appropriately.

KEEP ALL SHIELDS, GUARDS AND COVERS IN PLACE WHILE OPERATING THE BUCKER.

BEFORE OPERATION

7

OPERATION

8

CHECK YOUR WORK AREA

For your safety and the safety of others, always inspect the area before operating

the bucker.

Objects: Anything which can be grabbed by the rotating rubber rollers is a poten-

tial hazard to you and others. Look for hazards and remove them from the work

area. Tie back loose clothing and long, loose hair. Remove any jewelry.

SAFE OPERATING PRECAUTIONS

Before operating the bucker for the rst time, please review both the Bucker SAFE-

TY section (page 3) and the BEFORE OPERATION section (page 7).

Even if you have operated other buckers, take time to become familiar with how

the Triminator works.

Never tamper with or alter any of the controls or safety devices on the bucker.

Do not operate on slopes.

Never operate Triminator while under the inuence of drugs, alcohol or prescrip-

tions, including over-the-counter cold/u medications and allergy medications.

Protective clothing and eye and/or hearing protection should be worn during oper-

ation.

For your safety, do not operate while wearing loose-tting clothing, jewelry, etc..

Long hair should be secured in a manner that keeps it away from mechanical parts.

Rotating machinery parts can entangle loose clothing, long hair or dangling jewelry

resulting in serious injury or death.

CONTROLS

9

NOTICE: The BuckMaster series oers redundancy controls for safe operation. In

order to operate all controls must be in an active position and the emergency stop

must be in an operating position.

FORWARD/REVERSE SWITCH

Controls the direction of the

rollers.

SPEED CONTROL DIAL

Adjusts roller speed

POWER SWITCH

Activates power to the unit.

START STOP

Activates the forward/reverse

switch.

STARTING THE BUCKER

10

CONNECT POWER CORDS

1. Connect the Triminator BuckMaster power cord to a 15 amp 120 vac AC circuit.

Do not connect and disconnect the power cord with wet hands. Do not operate in

the rain.

The Triminator machine draws a max of 7 amps.

STARTING THE MACHINE

1. Align the Triminator BuckMaster power switch to the ON

position.

2. Press the start/stop switch to the START position.

3. Press the forward/reverse switch to the FORWARD position.

4. Adjust the speed control dial to the desired speed.

STOPPING THE MACHINE DURING NORMAL OPERATION

To stop the Triminator during normal operation, press the start/stop switch to the

STOP position.

STOPPING THE MACHINE DURING AN EMERGENCY

To stop the Triminator in an emergency, press the emergency stop button. The

emergency stop button will remain depressed until it is reset.

RESETTING THE MACHINE FOLLOWING AN EMERGENCY STOP

For the safety of the operator the machine must be reset following an emergency

stop.

1. Return Emergency Stop to the Active Position by rotating the red

button clockwise until it returns to it the fully extended position.

2. Align the Power Switch to the O position

3. Push the start/stop switch to the STOP

4. Forward/Reverse - Neutral (centered)

5. Start the machine as you would under normal operation conditions

DISCONNECT POWER CORDS

Disconnect the bucker’s power cord by pulling on the power cord plug.

NOTICE: Be sure to hold the plug when disconnecting the power cord from the elec-

trical outlet. Do not disconnect by pulling on the power cord.

BUCKING TIPS

11

For best eciency, run batches of similar sized material through the machine. In

general dry product should be run at a slower speed than wet product to achieve

similar results. Use the smallest hole or tube dia available to avoid losses.

WET BUCKING

For greatest eciency bucking wet product use the holes bucking plate. Set the

speed to the fastest setting allowable without excessively breaking apart the buds.

If the buds are being broken down to a point that is unacceptable slow the speed

until the desired result is achieved.

DRY BUCKING

For greatest eciency bucking dry product use the tubes bucking plate. Set the

speed to the fastest setting allowable without excessively breaking apart the buds.

If the buds are being broken down to a point that is unacceptable slow the speed

until the desired result is achieved.

REMOVING OBSTRUCTIONS

If the rotating rollers becomes restricted or clogged:

1. Stop the motor and verify all switches are in the stop or o position.

2. Make sure that all rotating parts have come to a complete stop.

3. Disconnect the bucker’s power cord.

4. Release the tension on the rollers by pulling the handle down and towards the

operator.

5. Remove the obstruction.

SERVICING YOUR BUCKER

Proper maintenance is essential for safe, economical, and trouble-free operation.

To help you properly care for your bucker, the following pages include a mainte-

nance schedule. Other service tasks that are more dicult, or require special tools,

are best handled by professionals and are normally performed by a Triminator

technician or other qualied mechanic.

The maintenance schedule applies to normal operating conditions. If you operate

your bucker under severe conditions, such as sustained high-load or high-tempera-

ture operation, or use it in unusually wet or dusty conditions, consult your servicing

dealer for recommendations applicable to your individual needs and use.

Remember that an authorized Triminator servicing dealer knows your bucker best

and is fully equipped to maintain and repair it. To ensure the best quality and reli-

ability, use only new, Triminator Genuine parts or their equivalents for repair and

replacement.

NOTICE: Improper maintenance, or failure to correct a problem before operation,

can cause a malfunction in which you can be seriously hurt or killed.

Always follow the inspection and maintenance recommendations and schedules in

this owner’s manual.

MAINTENANCE SAFETY

12

Some of the most important safety precautions follow. However, we cannot warn

you of every conceivable hazard that can arise in performing maintenance. Only

you can decide whether or not you should perform a given task. Failure to proper-

ly follow maintenance instructions and precautions can cause you to be seriously

hurt or killed. Always follow the procedures and precautions in this owner’s manu-

al.

Safety Precautions

Make sure all motors are o and power cords are unplugged before you begin any

maintenance or repairs.

Read the instructions before you begin, and make sure you have the tools and skills

required.

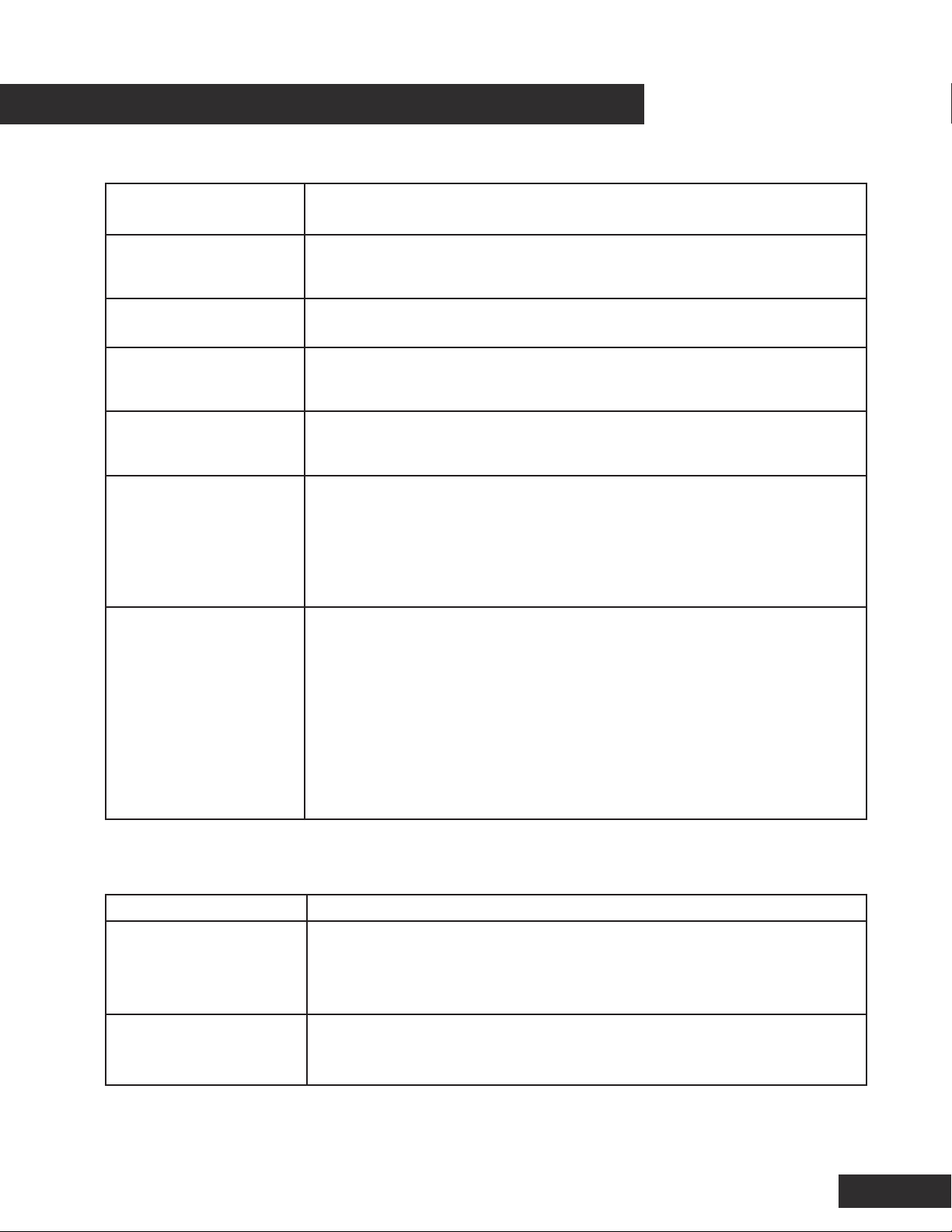

MAINTENANCE SCHEDULE

INTERVAL ITEM

Before each use

Insure the rollers are in the tensioned position with the roller handle

in the vertical upwards position.

Check that machine is free of excessive debris.

Ensure that machine is clean.

After each use

For best performance and longevity, release the tension on the roll-

ers by pulling the roller handle down to a horizontal position. This

reduces tension on the rollers and prevents them from attening

over time.

After each use

For best performance and longevity, clean bucker after every use or

if plant material is visibly aecting the quality or speed of the buck-

er.

After cleaning Grease metal to metal interfaces on roller assembly with food safe

grease after pressure washing.

Every 80 hours of

operation

Check the rubber roller wheels. To do this remove the rear guard (lo-

cated on the out-feed side of the roller assembly) for signs of wear,

cracks or breaks. Replace as needed.

DISASSEMBLE FOR CLEANING AND SERVICE

13

CLEANING

When to Clean:

Depending on the material being processed and the frequency of use, the holes

and tubes of the bucking plates may need to be cleaned. Additionally resin may

build up on the rollers over time requiring cleaning.

Indications that machine requires cleaning

1. Reduced bucking quality.

2. Visible build-up of material on the bucking plate which obscure the holes or

tubes. Visible evidence of material on the rubber rollers.

4. Excessive noise (machine should run quietly so that you may converse normally

when it is running)

Disassemble for Cleaning:

1. Shut o motor. Unplug power cords.

2. Release tension on the rubber rollers:

a. Pull roller handle down into the horizontal position

3. Remove roller guard:

a. With motor o, power cords unplugged loosen and remove the two thumb

screw on top of the roller assembly.

b. Pull roller guard up and away from roller assembly.

DISASSEMBLE FOR CLEANING AND SERVICE (CONT)

14

Roller Guard

Roller Guard Thumb Screws

CLEANING AND REASSEMBLY

15

NOTICE: For best results use hot water whenever possible. The rubber rollers are

rated for up to 150 degrees Fahrenheit. When using a hot water pressure washer

do not exceed 150 degrees Fahrenheit.

NOTICE: To clean the rubber rollers use either a standard household dish soap or

denatured alcohol. Immediately following the use of either cleaning agent, rinse

rollers throughly with water to remove cleaner.

Do Not select any other degreaser or cleaner as it that it may damage the rubber

rollers or any painted or anodized components of the bucker. Always follow the

operating instructions provided with the pressure washer.

NOTICE: If you choose to use a pressure washer take care not to damage the buck-

er’s nish by holding the nozzle excessively close to the machine or by focusing

the spray onto the motor or controller. A distance of 3 feet or greater is recom-

mended.

Pressure Washer Cleaning

1. Using a pressure washer, spray the bucking plates of the machine until they are

clean and clear of debris.

2. From a distance of at least three feet, pressure wash the roller assembly from the

back. Getting closer than three feet with the pressure washer nozzle may result in

damage to the rollers. If nicking or marking is occurs on the rollers, increase dis-

tance from nozzle to rollers.

Hand Cleaning

1. Using warm/hot water, concentrated dish soap and a non-metallic dish scrubber,

clean the bucker plate, rollers, and other machine components by hand.

CLEANING AND REASSEMBLY (CONT)

16

Re-assembly:

1. Verify motor is in the O position and power cord is unplugged.

2. Install roller guard.

1. Place roller guard on lower thumb screws on the bottom of the roller as

assembly.

2. Align holes on top of roller assembly and install thumb screws on top of

roller assembly.

TAKING CARE OF UNEXPECTED PROBLEMS

17

ELECTRIC MOTORS WILL NOT START OR HAVE LOW POWER

POSSIBLE CAUSE CORRECTION

Emergency Stop is

Depressed

If emergency stop button has been activated follow the reset

instruction on page 9.

No electric power

from the outlet Plug bucker into a functional electrical outlet.

Rollers experiencing

excess friction

Rollers may be dirty or jammed. Clean roller assembly and check

for jams.

Outlet is overloaded Check that breaker is not overloaded and has not tripped. If

tripped, switch plug to a dierent circuit.

Extension cord is

faulty

Check that extension cord, if used, is rated appropriately for

the distance and current. Do NOT use a longer cord unless the

wire size is larger. Undersized extension cords may cause an

under-voltage, over-current condition which could damage or

destroy the drive motor and void the motor warranty.

Over-current circuit

has been exceeded

Determine the cause of the excessive circuit resistance which

may include: overloaded outlet, faulty extension cord, bad out-

let, underrated generator, excessively dirty machine, incorrectly

tensioned shear band or an obstruction between the drum or reel

and another part of the machine.

Once the source of the resistance has been identied and re-

solved, reset the circuit by pressing the small button on the con-

trol panel for 3 seconds then operate the machine normally.

MATERIAL OBSTRUCTION/JAMS IN MACHINE

POSSIBLE CAUSE CORRECTION

Roller Wheels are

slipping

Reverse roller speed direction and eject plant material. If this

fails to correct the problem, turn o and unplug the machine.

Pull down the roller handle to release tension on the rollers.

Manually remove the plant material.

Material is not being

pulled through ma-

chine.

Verify that the Roller handel is in the vertical position and that

the roller wheels are engaged with one and other.

TAKING CARE OF UNEXPECTED PROBLEMS (cont)

18

CUSTOMER SERVICE

For all customer service inquiries or to help you diagnose any issues with

your machine contact Triminator directly:

Phone: 530.265.4277

Email: info@thetriminator.com

Web: www.theTriminator.com

BUCKING QUALITY HAS DECREASED

POSSIBLE CAUSE CORRECTION

Rollers or bucking plates

are excessively dirty Clean rollers and bucking plates.

MACHINE MAKES A LOUD SCRAPING, CLICKING, OR THUMPING SOUND

POSSIBLE CAUSE CORRECTION

Rollers or bucking plates

are excessively dirty Clean rollers and bucking plates.

Rollers have a at spot

Rubber rollers can become at over time if pressure is not re-

leased. If this occurs the rollers will make a thumping and slight

banging sound. To correct run machine at a low speed until

thumping dissipates. Do not buck any product until rollers have

returned to round.

ROLLERS DO NOT PULL

POSSIBLE CAUSE CORRECTION

Drum and Shear Band

are excessively dirty

Clean Drum and Shear band; excessive plant material has built up

on these surfaces and is causing excess friction.

LIMITED WARRANTY

19

TRIMINATOR EQUIPMENT

This warranty is limited to the Triminator Trimming Machine distributed by Mosman

Machinery Company, Inc., Nevada City, California 95959. The following warranty

applies to all Triminator products purchased directly or from retail outlets after

January 1, 2013.

LENGTH OF WARRANTY

All Triminator products are covered under this warranty for a length of 24 months

from the date of original purchase.

TO QUALIFY FOR THIS WARRANTY:

The product must be purchased in the United States, directly from Mosman Ma-

chinery Company, Inc. or from a dealer authorized by Mosman Machinery Company,

Inc. to sell those products. This warranty applies to the rst retail purchaser during

the applicable warranty time period.

WHAT WILL BE REPAIRED OR REPLACED UNDER WARRANTY:

Mosman Machinery Company, Inc. will repair or replace, at its option, any part that

is proven to be defective in material or workmanship under normal use and proper

maintenance as prescribed in this Manual during the applicable warranty time pe-

riod. Warranty repairs and replacements will be made without charge for parts or

labor. Any part replaced under warranty becomes the property of Mosman Machin-

ery Company, Inc. All new parts replaced under warranty will be considered as part

of the original product, and any warranty on those parts will expire coincident with

the original product warranty.

TO OBTAIN WARRANTY SERVICE:

You must call Triminator/Mosman Machinery Company, Inc. to discuss the warranty

issue.

Phone: 530.265.4277

Following the qualifying phone conversation Mosman Machinery Company, Inc.

may direct you to do one of the following:

At your expense, take the Triminator product, part to be replaced, or the equipment

on which the part to be replaced is installed, and a proof of purchase to the Trimi-

nator dealer from whom you originally purchased the product, during the dealer’s

normal business hours.

Alternatively, Mosman Machinery Company, Inc. may direct you in writing (email)

to deliver your product to a dierent location at a distance less than or equal to the

distance from your current location to the dealer from which you originally pur-

chased the product.

Table of contents

Other Triminator Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Nordson

Nordson PatternJet 1065924 Customer product manual

GUS

GUS GGW Assembly instructions

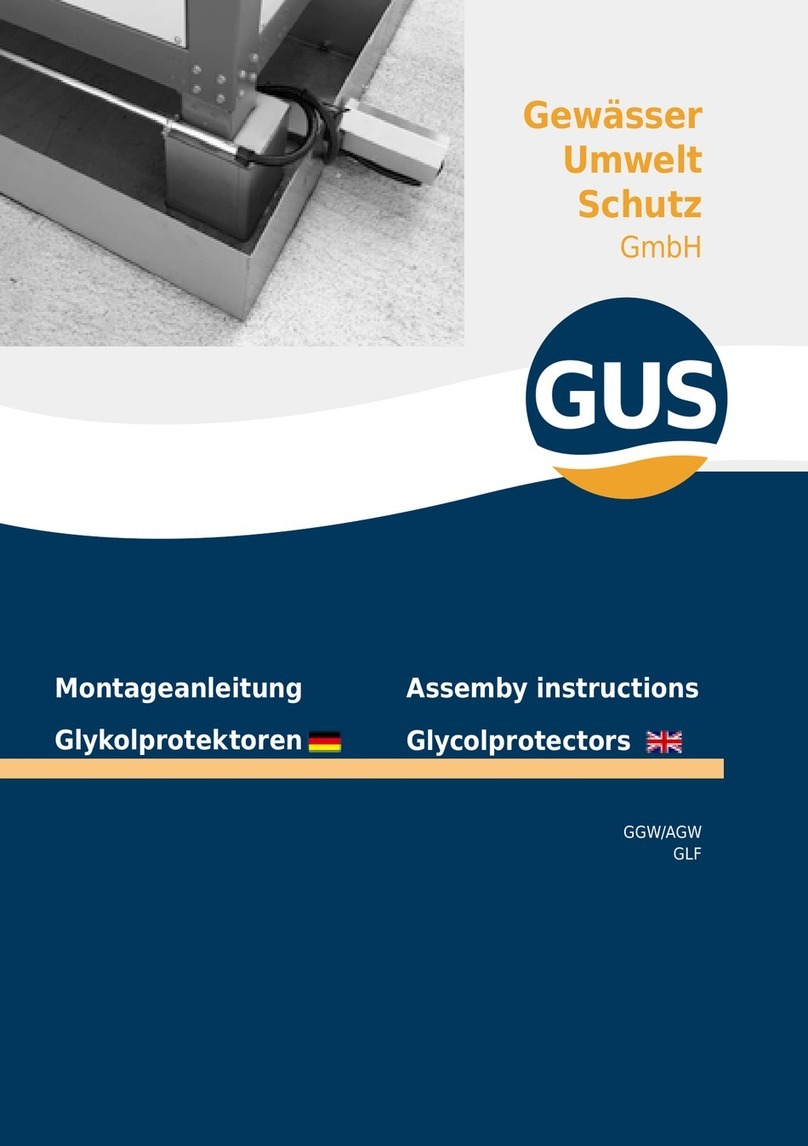

EHC

EHC NT Handling and installation guide

PRM NEWAGE

PRM NEWAGE 415 Series Workshop manual

Xylem

Xylem McDonnell & Miller PSE-800-M Application, Installation, Operation, and Maintenance Manual

MICRO-EPSILON

MICRO-EPSILON interferoMETER operating instructions