03

Use of the clay pigeon traps

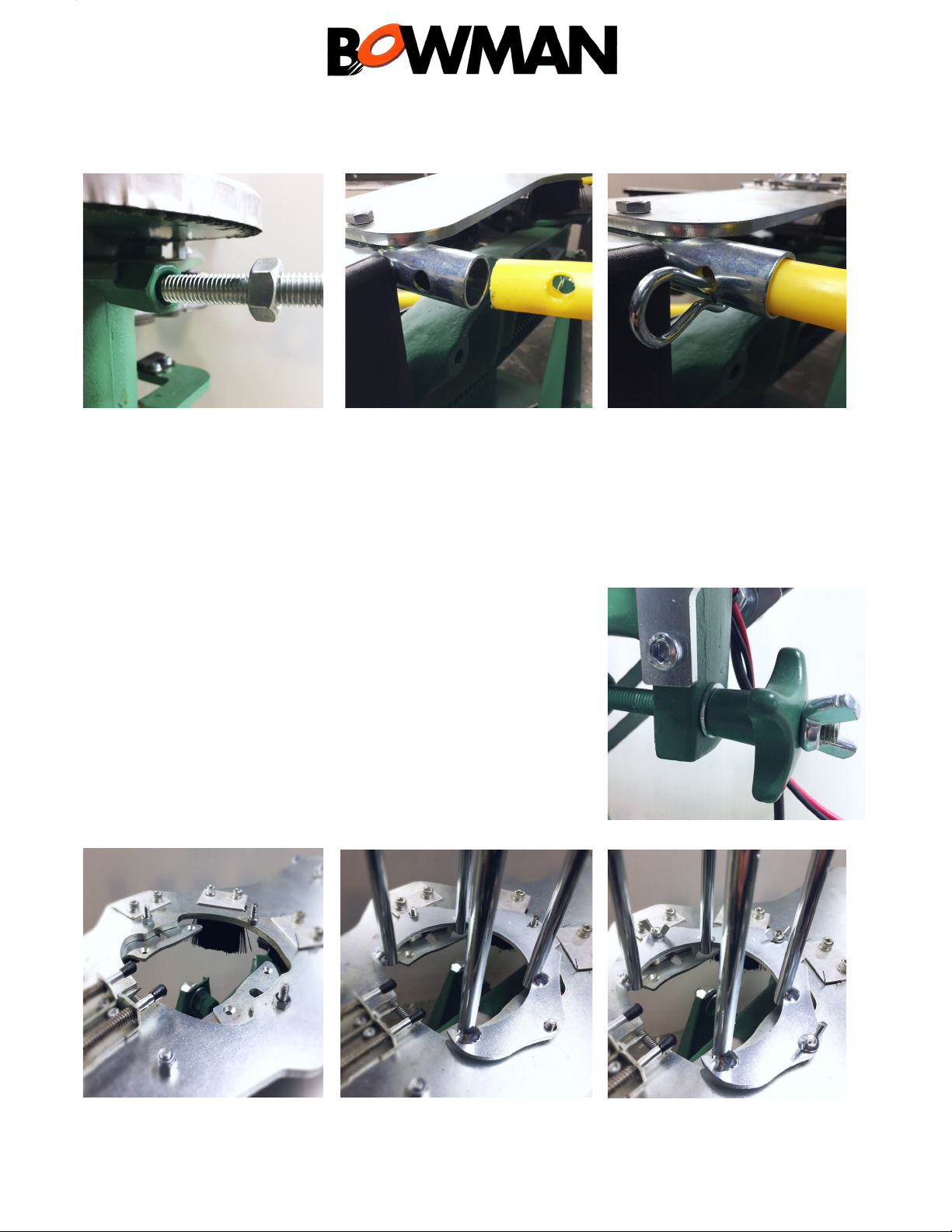

With all three tasks complete, the trap is now ready to connect to the battery. Do not add clays into the hoppers at

this point. When preparing to connect to the battery move to a safe position at the rear of the trap and make sure

that NO-ONE is in the DANGER ZONE in front of the trap or inside the area marked out by the safety ring.

Connect the radio receivers to the green sockets on the traps, check that the control box switches are in the off

position and then connect the crocodile clips to the battery. To arm the traps, turn the program switches to ’on run,

the traps will power up and the motor will rotate the throwing arms and stop in the firing position. Fire the trap by

pressing the wireless control (notice that the traps re-arm themselves ready to fire again). Now you must disarm the

traps in order to load clays and make elevation adjustments.

Disarm and make safe

To disarm and make the traps safe you ‘flick’ the program switches to ‘nudge fire’. Notice the traps will fire, but do

not re-arm with the throwing arms visible to the left. Remove the crocodile clips from the battery. Load your clays

gently into the hoppers, being careful not to drop them onto the spike (wet clay separator). To make elevation

adjustments, release the lever lock, tilt the trap backwards to the desired height and then re-tighten the lever lock.

Now you are ready to re-attach the crocodile clips (ensuring the program switch is set to ‘off’) and then switch the

program to ‘on run’ in preparation to fire clays.

Note: When the traps are armed and ready to fire, turning the program switches to off will not make them safe, they

MUST be de-cocked using nudge fire and the power source removed before being completely safe.

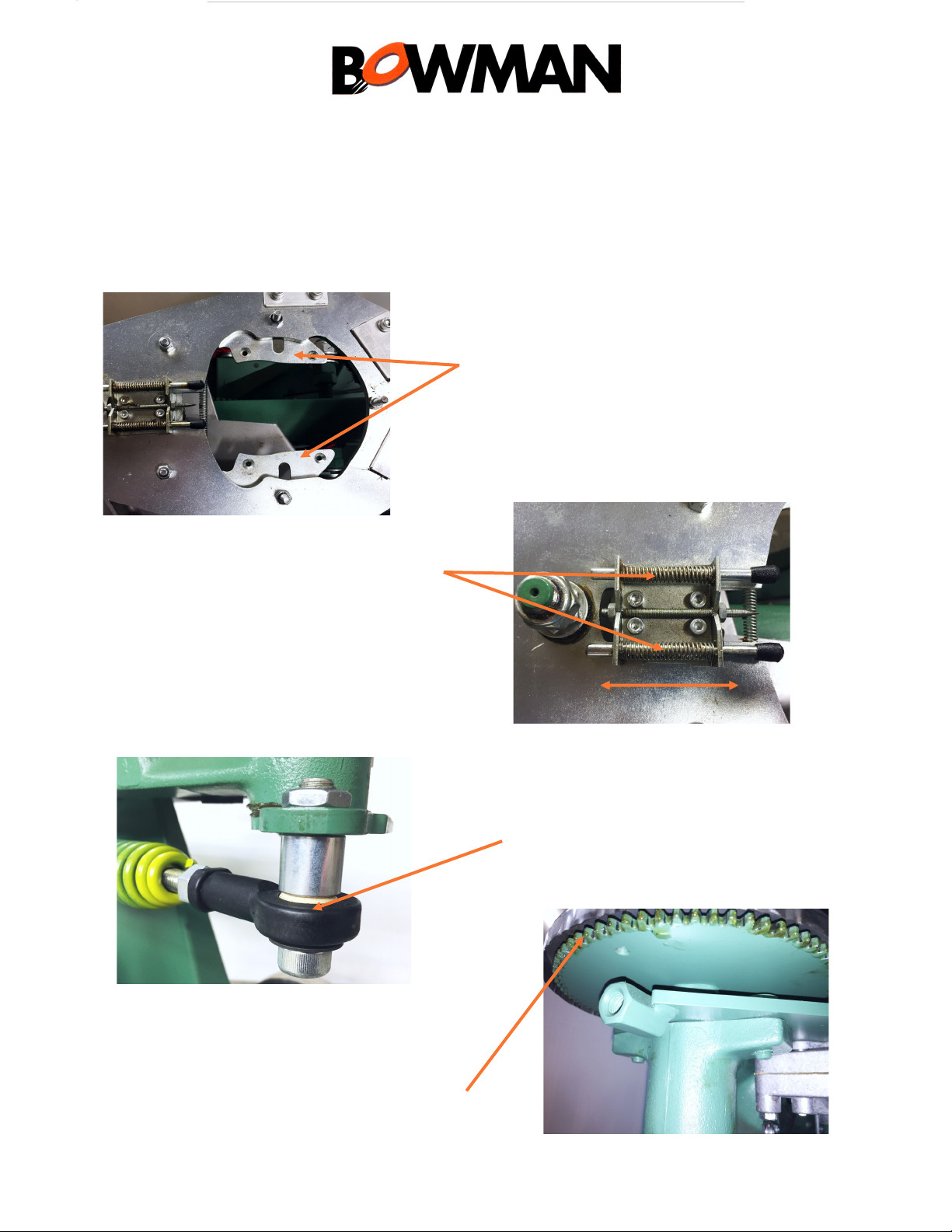

Operating the wobble base

To operate your wobble base connect to a 12v battery. Moving the switch to the right will nudge the traps in small

increments and clicking it fully over to the left with engage continuous left to right movement. You can run the

traps and movement from one battery however the battery will loose charge quicker. There are two battery trays

on your mini game trailer if you prefer to the run the system off two batteries.