ENGINE DRIVEN WELDERS

Publication E13 13 2/07

Web Update 5/08

www lincolnelectric com

Mobiflex™400-MS

Mobile Welding Fume Extractor

ENVIRONMENTAL SYSTEMS

Advantage Lincoln

• Generous 735 CF airflow with LFA 3.1/4.1 extraction arm(1).

• Filter efficiency up to 99.8%(2).

• Generous 30 m2(325 ft2) filter cartridge with ExtraCoat®pretreatment.

• Electronic differential pressure system monitors internal static pres-

sure and controls filter cleaning.

• Indicator light for saturated filter.

• RotaPulse®automatic filter cleaning system.

• Internal aluminum mesh spark arrestor.

• Low noise operation: 69dBA.

• One-year warranty on unit; 30 days on filter, hoses and hose

adaptors.

Mobiflex™400-MS S stem includes:

• Filter, plastic housing, 8" flexible hose, 6 meter (19 ft.) 115VAC input

power cord and instruction manual.

NOTE: Extraction Ar of your choice is required.

(1)CFM level is dependent upon ar length, fan type and syste aintenance.

(2)Per Din EN 60335-2-69 Standards.

Lincoln Electric’s®Mo iflex™400-MS is a porta le, low vacuum/high volume self-cleaning filtration

system designed for heavy duty extraction and filtration of welding fumes.

The lightweight and rugged design of the Mo iflex™400-MS along with the standard front caster and

rear wheels allows for easy porta ility. It is ideal for facilities that require welding fume extraction in

multiple locations, including maintenance departments, general fabrication and job shops, and industrial

welding environments. Because of the self-cleaning function, the obiflex™400- S can also be used in

production environments where welding duty cycles are longer and more frequent.

The Mo iflex™400-MS can e configured with Lincoln’s LFA 3.1 or LFA 4.1

fume extraction arms or with the 152 mm (6") diameter, 5 m (16’) long flexi le

hose and hood set. Lincoln Electric’s®fume extraction arms are designed to

provide welders optimal motion and reach for their specific welding position(s)

and work area. The arm lengths range from 3.1 m (10 ft.) to 4.1 m

(13 ft.). For hard to reach areas such as confined spaces, the flexible hose

and set can be easily carried to locations where an extraction arm just is not

feasible.

The internal extraction fan is designed specifically for weld applications.

It extracts weld fume through the arm, into the internal spark arrestor and

finally through the self-cleaning filter cartridge capturing the welding fume

particulate. As the particulate is collected on the outside of the filter cartridge

and builds up, the filter is then automatically cleaned causing the particulate

to fall into the collection bin for easy, hands free disposal.

The Mo iflex™400-MS filter is recommended for consuma le use of approximately

6,000 lbs. (2722 kg) of IG wire or 4,000 lbs. (1814 kg) of stick or flux-cored wire before replacing.

Filter performance will be affected by process and application variables including:

base metal(s), consumables(s), and coatings (oil) if applicable.

Processes

Stick, TIG, IG, Flux-Cored

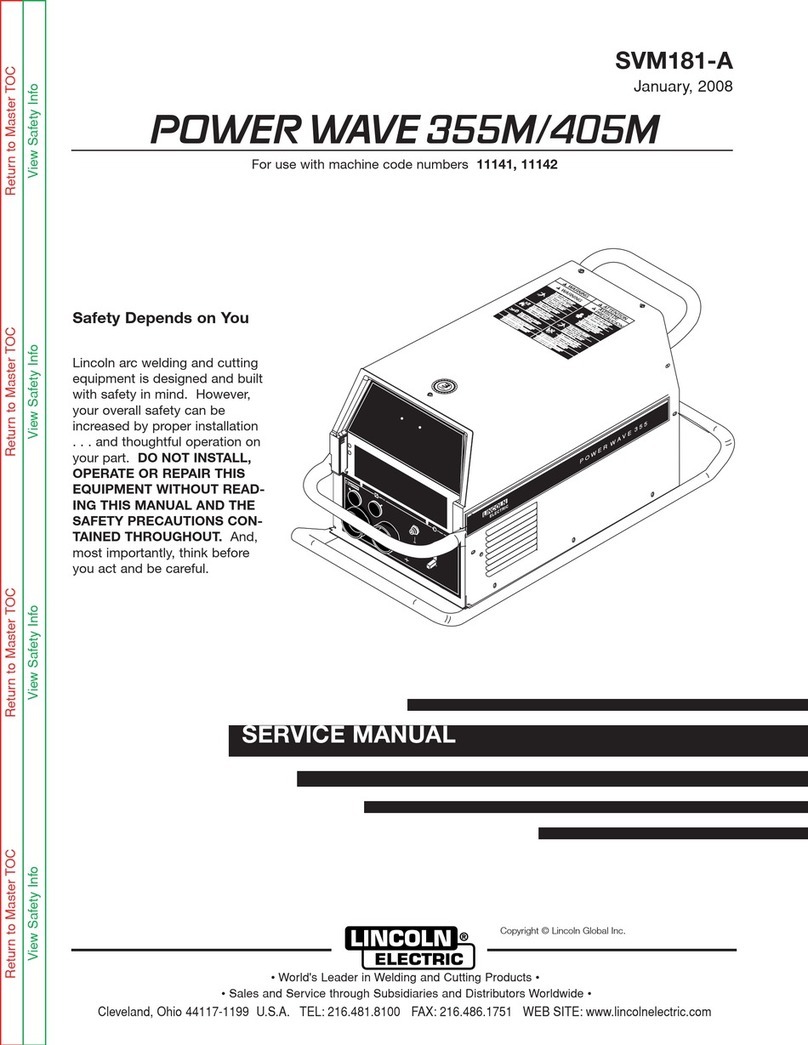

Shown:

Mobiflex™400-MS with

optional Extraction Arm

Input

TECHNICAL SPECIFICATIONS

Dimensions

Product Product Filter Type/ Input Input H x W x D Net Weight

Name Num er Filter Size Power Current mm (in.) kg (l s.)

obiflex™400- S K1741-1 Pretreated Cellulose 115/1/60 12A 1020 x 810 x1200 130

Base Unit 30 m2(325 ft2) (40 x 32 x 48) (286)