Page Number - 2

CENTRO-MATIC®

Form 403168

Table of Contents

Safety................................................................................................2

Controller Operation......................................................................2

Description......................................................................................2

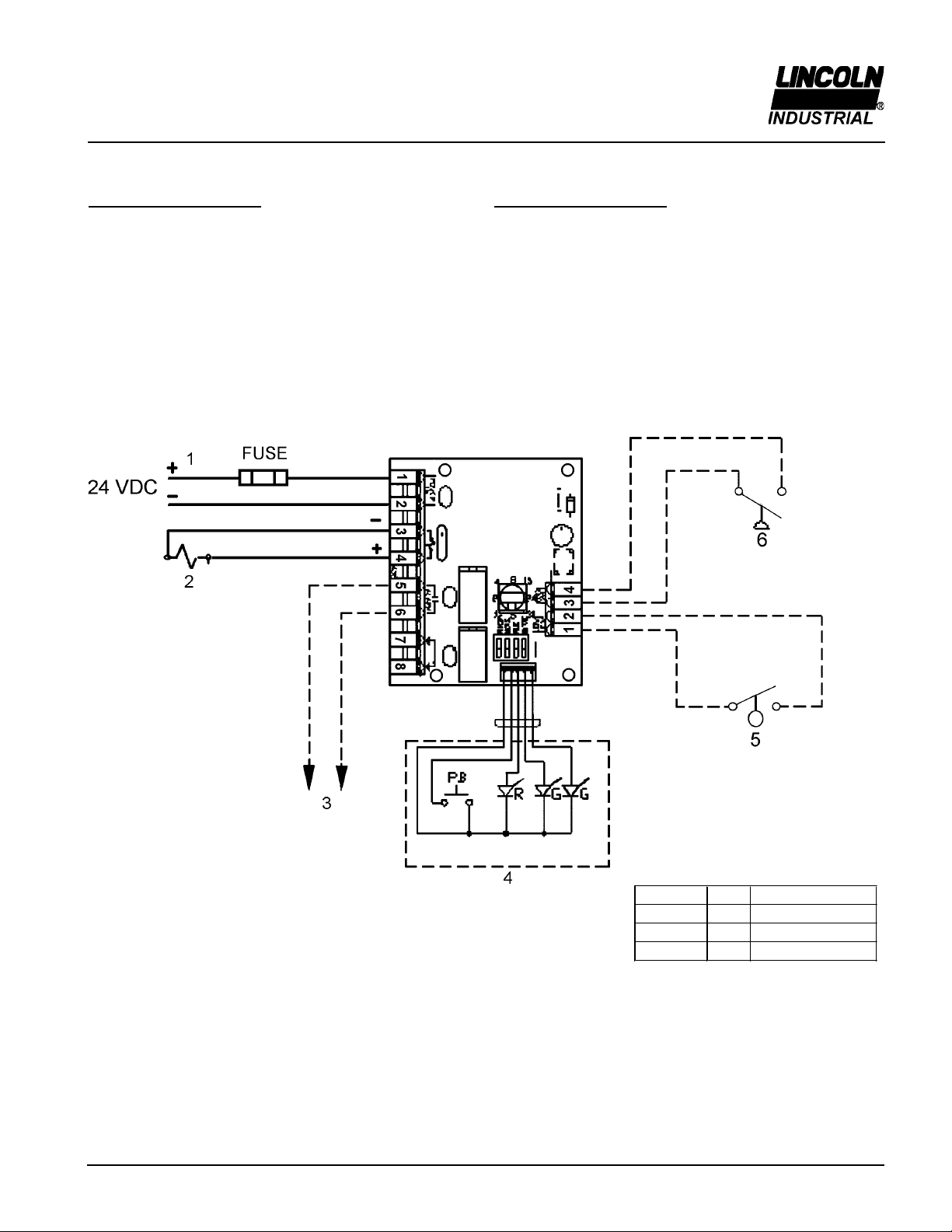

Field Connections..........................................................................3

Wiring Diagram..............................................................................3

Contoller Components and Setting the Controller....................4

Repair Parts List........................................................................4

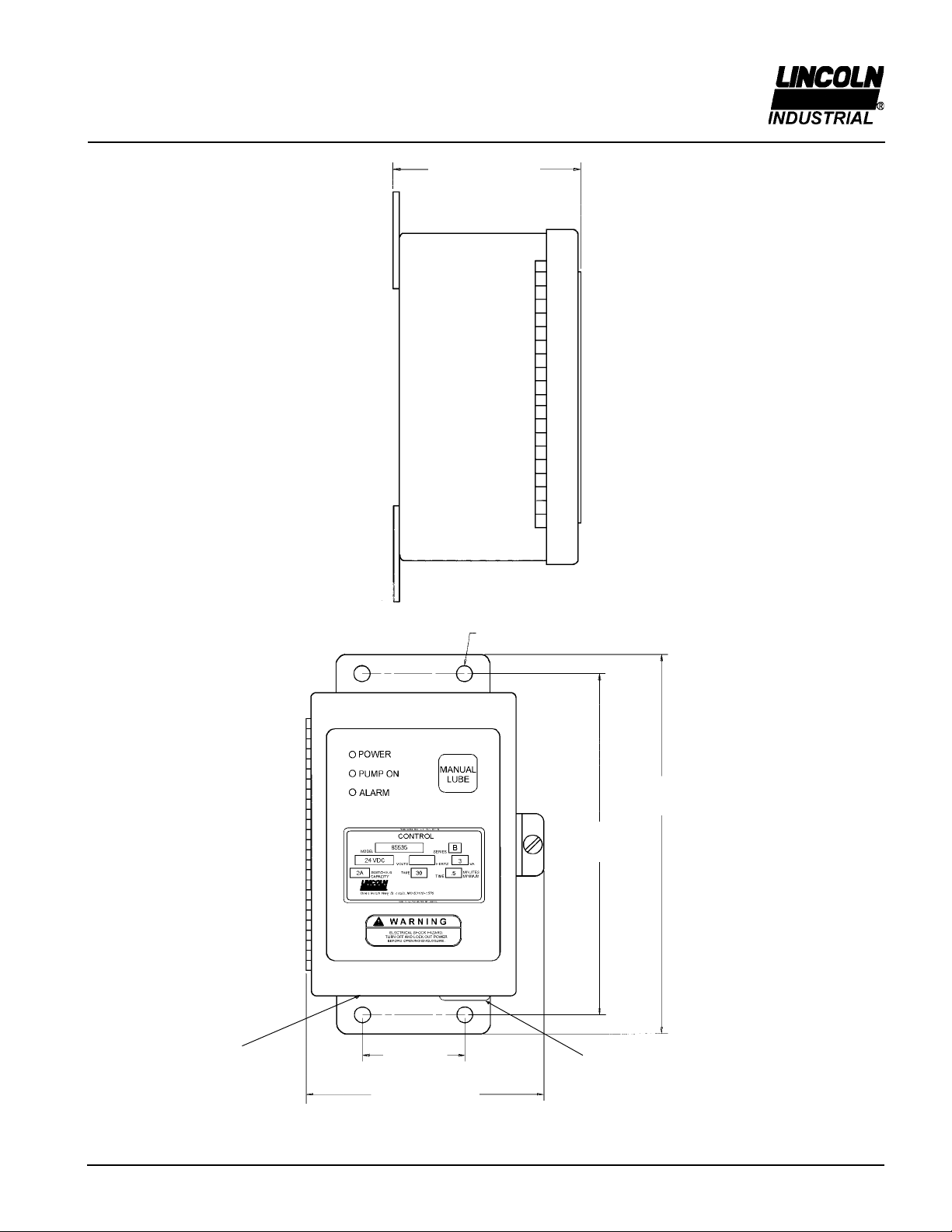

Dimensions....................................................................................

Troubleshooting....................................................................6

Safety

Read and carefully observe these operating instructions

before unpacking and operating the controller! The

controller must be operated, maintained and repaired

exclusively by persons familiar with the operating

instructions. Local safety regulations regarding installation,

operation and maintenance must be followed.

Operate this controller only after safety instructions and this

service manual are fully understood.

This symbol identifies

the potential for a

hazardous situation.

If this warning is not

followed, a serious

injury could occur.

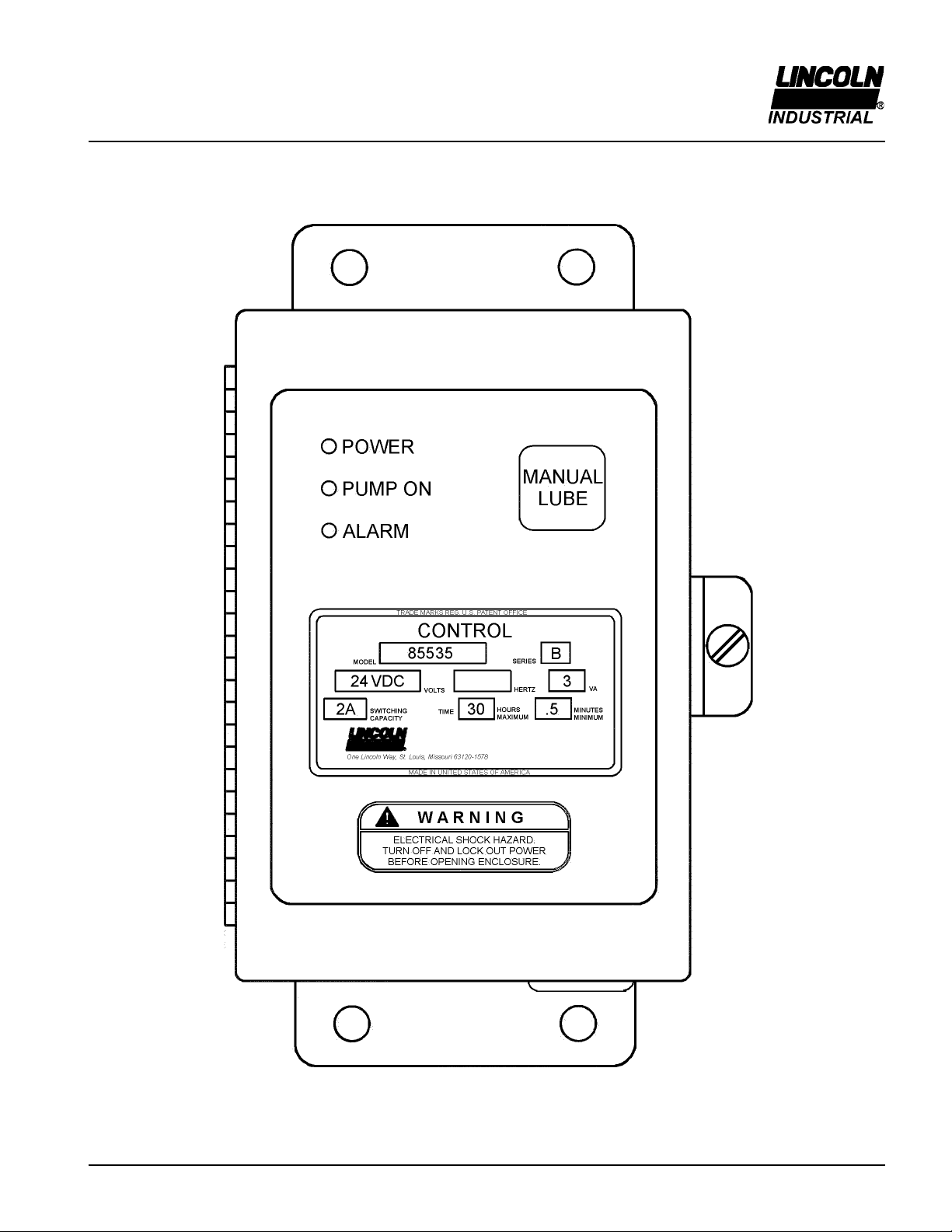

Description

General Description

Model 8 3 controller is used to program the cycle

frequency of a lubrication pump. Lube cycles are

determined by the setting of internal switches. The cycles

times are selected to meet system requirements. During

the ON time, the air to the pump solenoid will be

energized.

Appropriate Use

Model 8 3 is exclusively designed for use in a

Centralized Lubrication System.

The maximum ratings given should not be exceeded.

Any other use not in accordance with the instructions will

result in loss of claim for warranty and liability.

Product Specification:

Input Voltage: 21 VDC to 30 VDC

Current Consumption: 100 MA (less external load)

Load Relay Contact: 2 amps inductive load at 30 VDC

Alarm Relay Contact: 2 amps inductive load at 30 VDC

Enclosure: NEMA 12

Temperature Range: -40° F to 1 0° F (-40° C to 6 ° C)

Net Weight: 4 lbs.

O Time (adjustable): 30 seconds minimum

30 hours maximum

On Time: 30 seconds minimum

2 minutes maximum

Lubrication System: Centro Matic

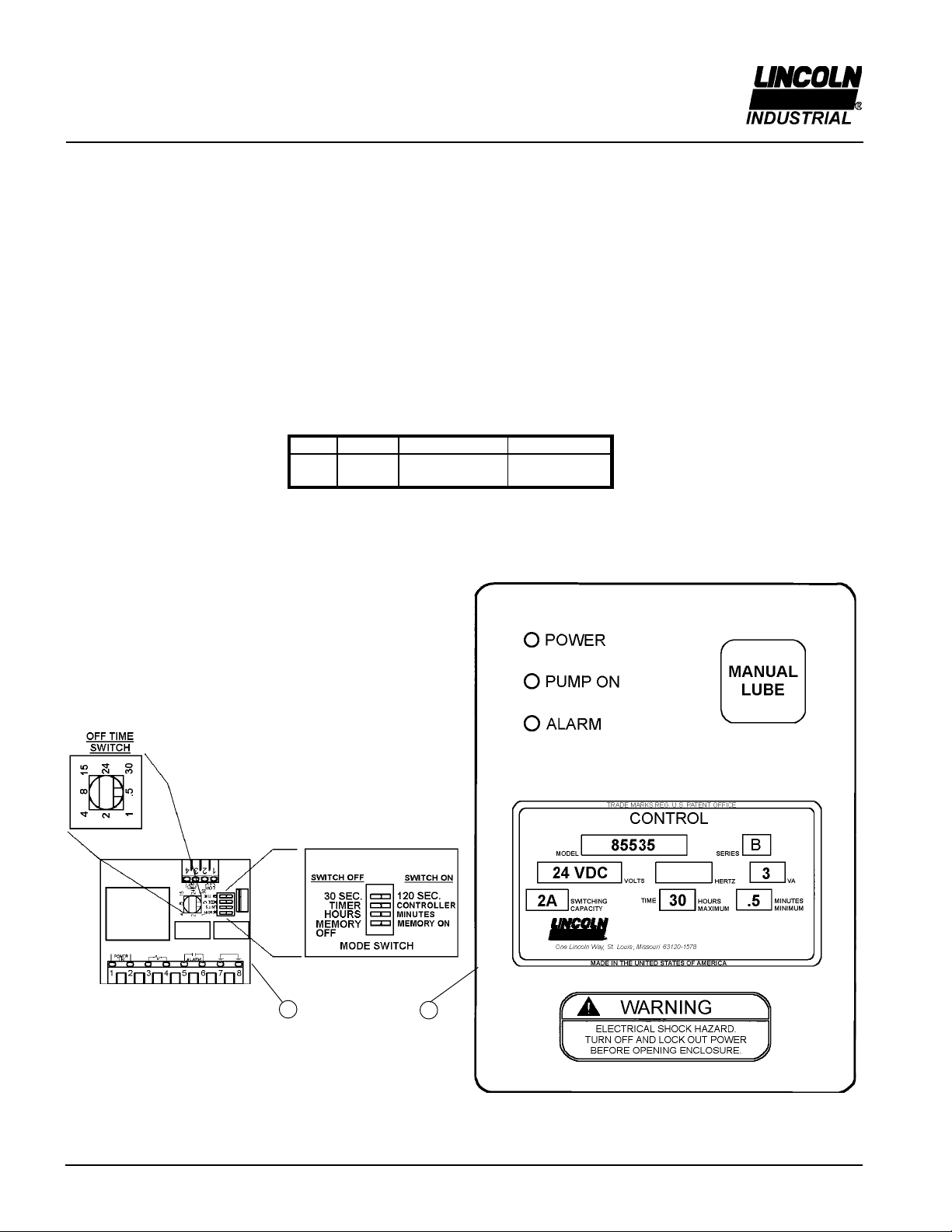

Controller Operation

The time between lube events is determined by the setting

of the rotary switch, which selects the numeral setting, and

the dipswitch, which selects the units in either minutes or

hours.

When used in the timer mode, the pump will remain on for

the amount of time that was selected by the dipswitch. Time

will be either 30 seconds or 2 minutes (see Timer Mode).

When used in the controller mode, the amount of time that

the pump is on is determined by the closing of a pressure

switch in the lube supply line (see Controller Mode). Failure

of the pressure switch to close within the time setting of the

dipswitch, either 30 seconds or 2 minutes, will result in an

alarm condition. The alarm LED will turn on and the alarm

contact will close. The controller will continue to initiate lube

cycles while in alarm.

When the low-level switch closes, the alarm LED will turn on

and the alarm contact will close. The controller will continue

to initate lube cycles while in alarm. Alarm condition will

remain until low-level switch opens.

Pressing the manual lube button on the enclosure cover will

always initiate a lube event.

The memory feature will work as follows:

Dipswitch set to Memory Off Will result in a lube cycle

each time power is turned on. Lube cycle will start at the

beginning of the on time setting.

Dipswitch set to Memory On

1. Power is turned off during the off time (time between

lube cycles). When turning power back on will cause the

lube cycle to continue from the point of interruption.

2. Power is turned off during the on time or pumping time.

Turning power back on will cause the lube cycle to start

at the beginning of the on time setting.

Timer Mode

When the dipswitch is set to the timer mode, amount of

time that the pump is on will be determined by the setting of

the dipswitch. Time will be either 30 seconds or 2 minutes.

Controller Mode

When the dipswitch is set to the controller mode, a

pressure switch must be installed in the lube supply line.

This will provide pressure-monitoring capabilities. The

pressure switch will reset the controller when the set

pressure is detected. The controller will initiate an alarm

when the pump fails to develop sufficient pressure to

actuate the pressure switch within the dipswitch setting of

30 seconds or 2 minutes.