Page Number - 3

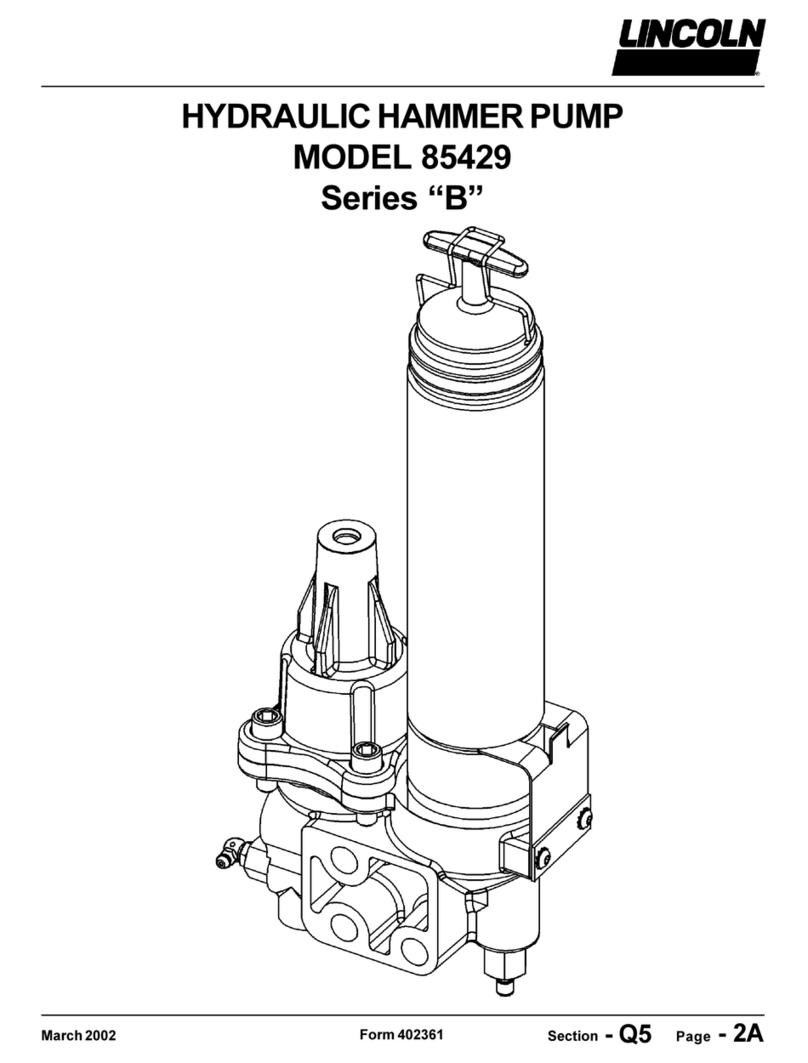

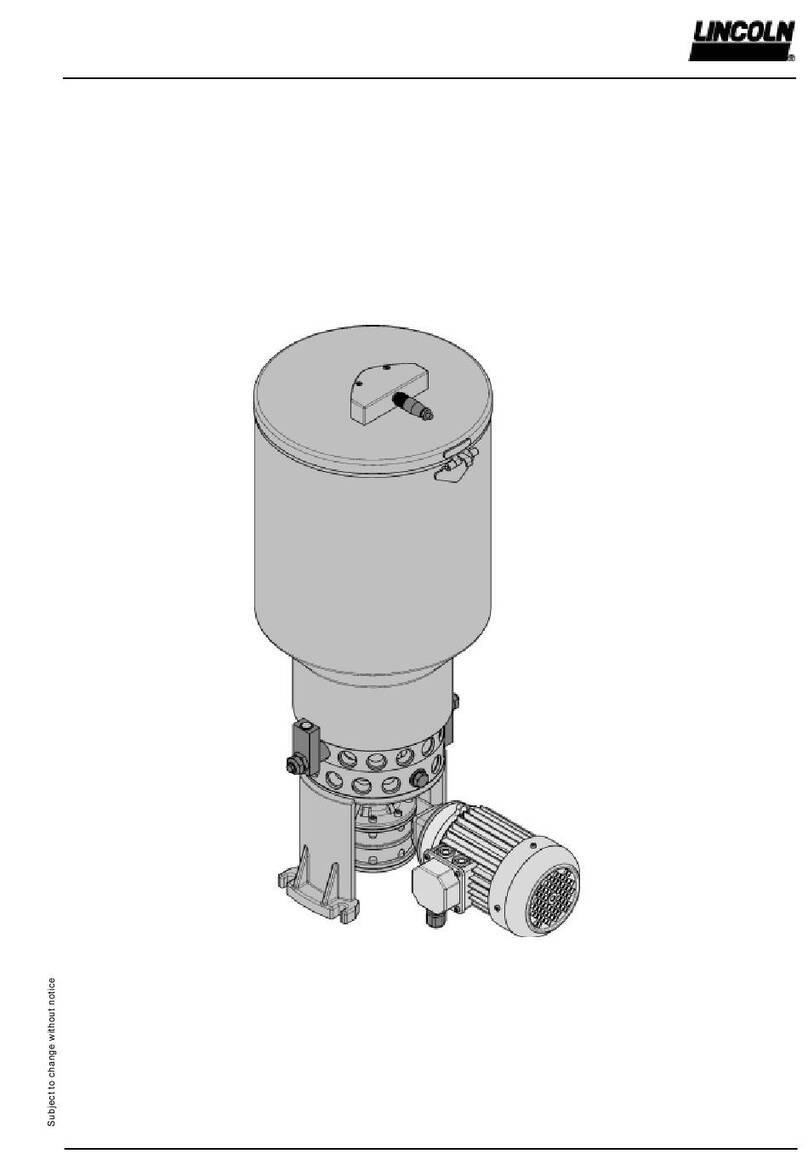

Hydraulic Hammer Pump

21A-30003-B00

Form 403079

Pump Operation

The pump operates simultaneously with the hammer.

Usually the carrier (exca ator, back hoe or skid steer) has a

foot pedal to operate the hammer. Each time the operator of

the carrier starts the hammer pushing the pedal, the pump

will make one stroke to dispense grease to the point of

lubrication. When operator stops the hammer, to reposition

or to start new work, the hydraulic pressure to the pump must

be ented and the springs (8, 9, and 10) will return the pump

plunger (6) into the initial position for the next lubrication

cycle. For proper pump operation, the inlet hydraulic back

pressure in the connecting hose has to be below 200 psig

(14 bar). As plunger opens the grease inlet port, grease

flows into the ca ity due to acuum in the ca ity and the

pressure exerted on the grease by the cartridge follower

spring (see Illustration 1).

Changing Pump Output

Pump is shipped with the metering plug (23) part number

270801, for minimum grease output - 0.018 in³ (0.3 cm³).

The output of the pump can be increased by changing the

metering plug (23):

-P/N 270802 -0.036 in³ (0.6 cm³)

-P/N 270803 -0.048 in³ (0.8 cm³)

-P/N 270804 -0.060 in³ (1.0 cm³)

-P/N 270805 -0.072 in³ (1.2 cm³)

Installing the Reservoir Retainer

Before installing the reser oir clip, make sure that the

Grease Cartridge Housing (28) and gasket (27) are in place

first. If grease cartridges are to be used, install a grease

cartridge in the Grease Cartridge Housing before final

adjustment of the spring clip.

Assemble the spring

clip (31) to the side of

the pump head (11) and

secure with the plate

(32) cap screws (34)

and lock washers (33)

as shown in the illustra-

tion. With the Grease

Cartridge Housing

installed, and securely

tightened (grease cartridge installed as required) adjust the

fingers of the spring clip so that they firmly retain the Grease

Cartridge Housing. The spring clip should be installed so

that the clip fingers pull the bottom of the groo e in the

Grease Cartridge Housing into the pump head. Tighten the

two cap screws (34).

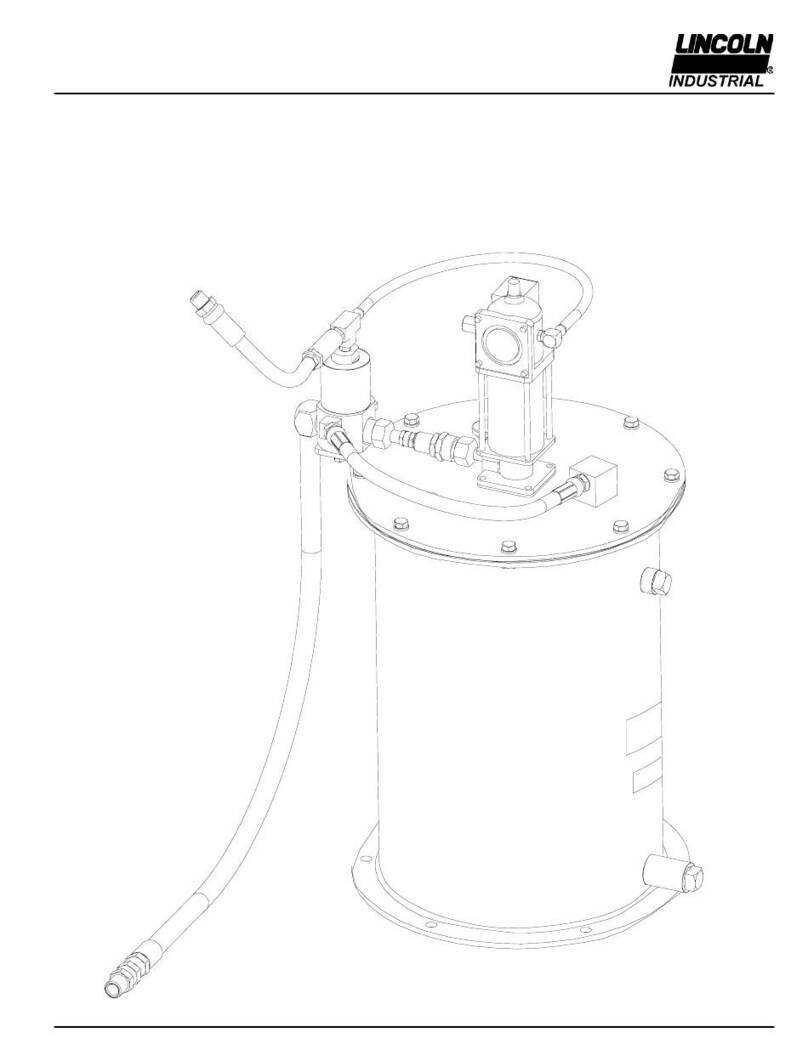

Installing the Pump

The pump should be installed directly on the hammer or

gripper/crusher. Preferable mounting of the pump is

cartridge housing (28) in the upright position, but it may be

mounted in a horizontal position as well. Make sure to

allow sufficient space for cartridge remo al to refill and

pump ser icing. Mount in area where the pump indicator

cap (18) will be isible to monitor cartridge lubricant le el.

1. Use two 1/2 in. (12 mm.) bolts to securely mount the

pump on an e en and solid surface of the hammer. If

necessary, fabricate a mounting bracket.

2. Connect hydraulic power supply to the pump inlet (see

Illustration 2). Use appropriate high pressure hose.

3. Fill the pump with grease. (See Filling Pump with

Grease and Air Purging instructions.)

4. Attach the lubricant supply hose to the pump outlet.

5. Prime the supply hose with grease.

6. Connect lubricant supply hose to the lubrication point.

IMPORTANT: Low Le el indicator rod (14) will extend from

bottom of pump when grease cartridge becomes empty.

See illustration 2. Replace empty cartridge promptly with a

new grease gartridge.

Filling Pump ith Grease

Removing Empty Cartridge

1. Disengage the retaining clip from

the follower handle as shown in the

illustration, below.

2. Pull the spring clip of the reser oir

retainer by grasping the finger tab on

the clip and disengage the clip fingers

from the housing groo e. Loosen the

Grease Cartridge Housing a couple of

turns to break the seal.

3. Pull back the follower handle until the follower rod is fully

extended and latch the follower rod groo e into the slot in the

tube cap.

4. Unscrew the grease cartridge housing (28) from the pump

head (11).

5. Carefully release the follower handle to eject the empty

cartridge from the container tube.

Installing Grease Cartridge

1. Visually check follower seal lip direction before loading a

new cartridge. The follower seal lip must be directed toward

the follower handle for cartridge loading. See illustration be-

low. To change the direction of the follower seal, unscrew the

tube cap from the container tube and pull on handle to re-

mo e the follower seal from the tube. Flip the follower seal

o er and re-assemble.

2. Pull back on the follower handle and latch the follower rod

groo e into the slot on the tube cap.

3. Remo e the plastic cap from the grease cartridge and

insert the cartridge into the container tube.

4. Remo e the pull-tab from the grease cartridge. Pull the

finger tab on the spring retainer (31) back to clear the grease

cartridge housing (28) as the housing is placed into the open-

ing in the pump head (11). Screw grease cartridge-housing

(28) into the pump head (11) and tighten.

5. Release follower rod from slot. Purge air from pump. See

air-purging instructions.

6. Latch the retaining clip o er the top of the follower handle

to pre ent the follower rod from protruding from the grease

cartridge housing.

31

32

33 34

11