Page Number - 3

CENTRO-MATIC® PUMP, MODEL 85219, 85220

Form 403228

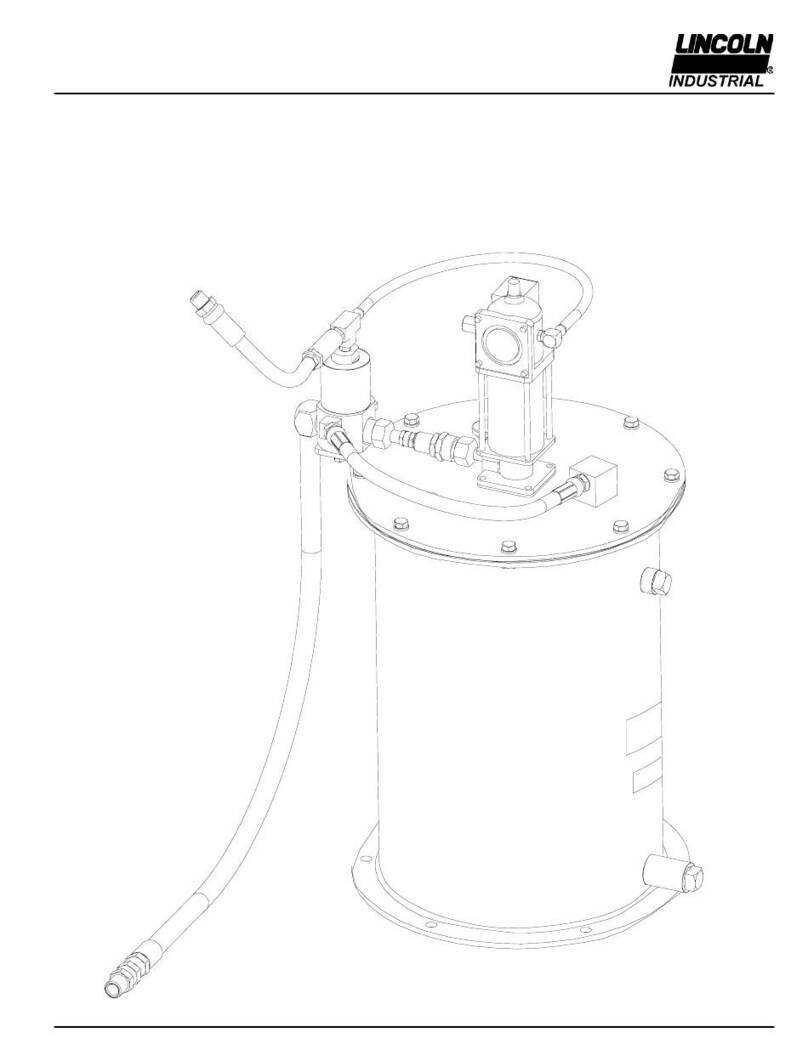

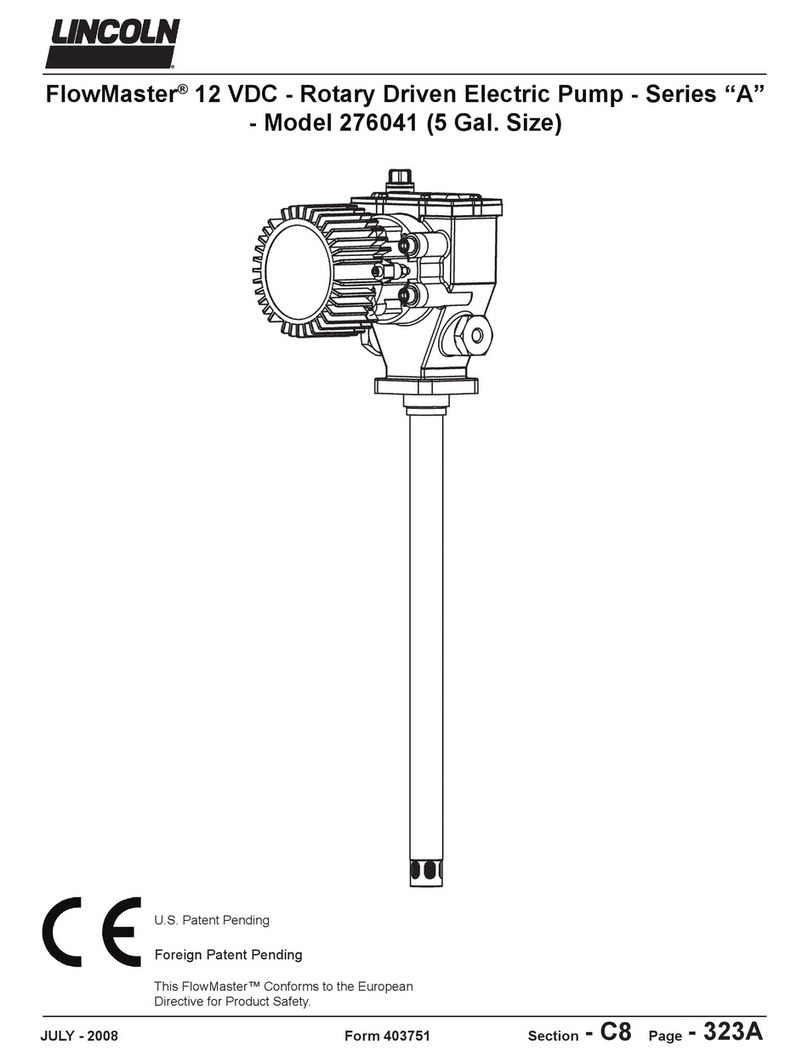

INSTALLING THE PUMP

Place the unit in the approximate location making sure that

electric and hydraulic power connections are accessible.

ark center locations of the four holes at the bottom of the

reservoir. Then drill four 5/8 (16 mm) holes. The use of

1/2 (13 mm) bolts will offer some flexibility in securing the

reservoir to the equipment.

Lubricant outlet of pump should be connected to system with

suitable hose capable of 3,500 PSI (241 bar) working

pressure. Hydraulic inlet connection should be made with at

least 3/8 (9 mm) I. D. hose capable of at least 3,000 PSI (207

bar) operating pressure. Hydraulic return to tank connection

line should be 3/4 (19 mm) I. D. hose or pipe.

Please refer to the 85481 operation manual, section C8, page

269, series B for setting the pump pressure and flow

control.

PUTTING PUMP INTO OPERATION

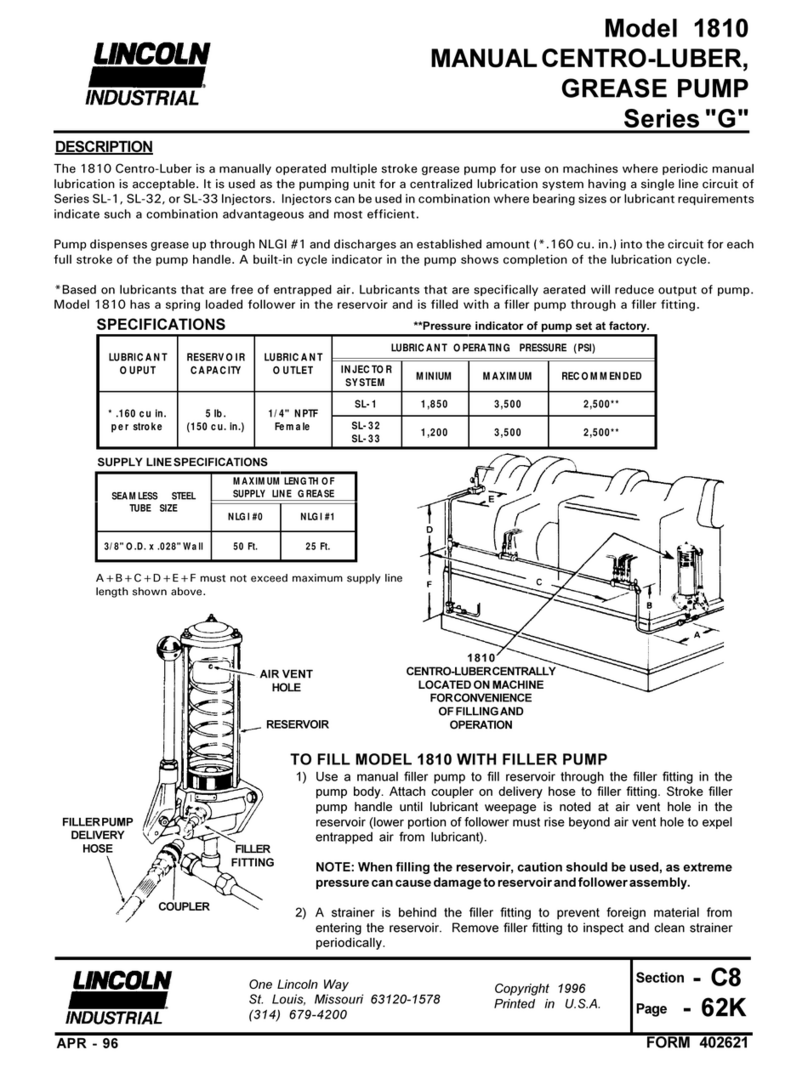

Filling eservoir

To bulk fill the reservoir, remove the lower and upper pipe

plugs from the side of the reservoir (see Figure 4). Attach the

appropriate bulk-filling pump to the lower inlet (3/4 NPT). Fill

reservoir until grease appears at the top 1/2 NPT vent high

level port. Remove the bulk-filling pump. Replace both pipe

plugs.

Each part is identified with a number keyed to the

matching part on the illustrated views.

General recommendations of tools required are also

specified in each step.

Pay particular attention to the Warning statements to

prevent personal injury and possible damage to pump

components.

Outlet Check Service

(See Figures 1, 2, 9 & 10, Pages 4, 5 & 6)

The pump will not build up sufficient lubricant pressure if the

outlet check (42) is fouled. Foreign material may lodge

beneath the Check Ball (21) or between check disc (17) and

the seat of bushing assembly (18). Sealing surfaces of the

seat must form a perfect seal. Clean parts or replace if

pitted, worn or scored.

1. Turn off and disconnect the hydraulic and electric power

supply to the pump assembly.

2. Standard tools required are a bench mounted vice, a set of

open end wrenches ranging from 7/16 to 1-1/2, a large

24 (600 mm) adjustable wrench and a smaller 10

(254 mm) adjustable wrench.

3. Remove bolts and lock washers (47 & 48 ).

4. Loosen adapter union. Set vent valve assembly to

the side.

5. Remove entire outlet check assembly (42) by loosening

adapter (41) from pump outlet.

6. Remove adapter (41) from outlet check assembly (42).

7. Remove outlet connector (22) from bushing (18).

8. Remove ball check seat (19) from outlet connector (22).

9. Inspect all check components (17, 18, 19, 21) for presence

of foreign material, scoring and or other damage, which

may cause internal leakage. Replace components if

damage is found.

10. If foreign material is present, clean components and

reassemble. Be sure to always replace gaskets (16) &

(20) whenever vent valve is disassembled. Reverse the

above procedure to reassemble. Torque check

assembly to 100 ft.-lbs. (13.5 N- ).

Vent Valve Service (See Figures 3, 9 & 10

Pages 5 & 6)

1. Turn off and disconnect the hydraulic and electrical power

supply to the pump assembly.

2. Standard tools required are a bench mounted vice, a set of

open end wrenches ranging from 7/16 to 1-1/2, a large

24 (600 mm) adjustable wrench and a smaller 10

(254 mm) adjustable wrench.

3. Loosen Adapter Union (43) and Vent Hose (14).

4. Remove bolts and lock washers (47 & 48). Remove vent

valve.

5. Hold base of vent valve in vice to remove elbows (12 & 15).

Turn vent valve in vice so that vice jaws are gripping flats

machined on base of vent valve.

6. Remove hydraulic cylinder (23). Remove piston and

packing (24) from cylinder. If oil leakage was evident

from side of hydraulic cylinder then replace packing.

When filling the reservoir, caution should be used as

extreme pressure can cause damage to the reservoir or

serious personal injury.

MAINTENANCE & REPAIR

General Maintenance

Keep area around pump clean. Clean off filling port area

prior to filling reservoir. Clean area around filler after filling

as lubricants will attract dirt.

Keep lubricants clean and free of dirt and debris.

When replacing grease pails be especially careful to

prevent any foreign matter from entering the grease pail or

contaminating the grease, as it adheres to the pump.

In Case of System Malfunction

(See Trouble Shooting Chart Page 8)

Use the Trouble Shooting Chart to determine where to

look if problems occur.

See the sections below for replacement and repair of

specific areas of the check valve, vent valve or safety

unloader valve.