LINCOLN GmbH & Co. KG Postfach 1263 D-69183 Wa dorf Te +49 (6227) 33-0 Fax +49 (6227) 33-259

2.1A-38018-A02

Owner Manual

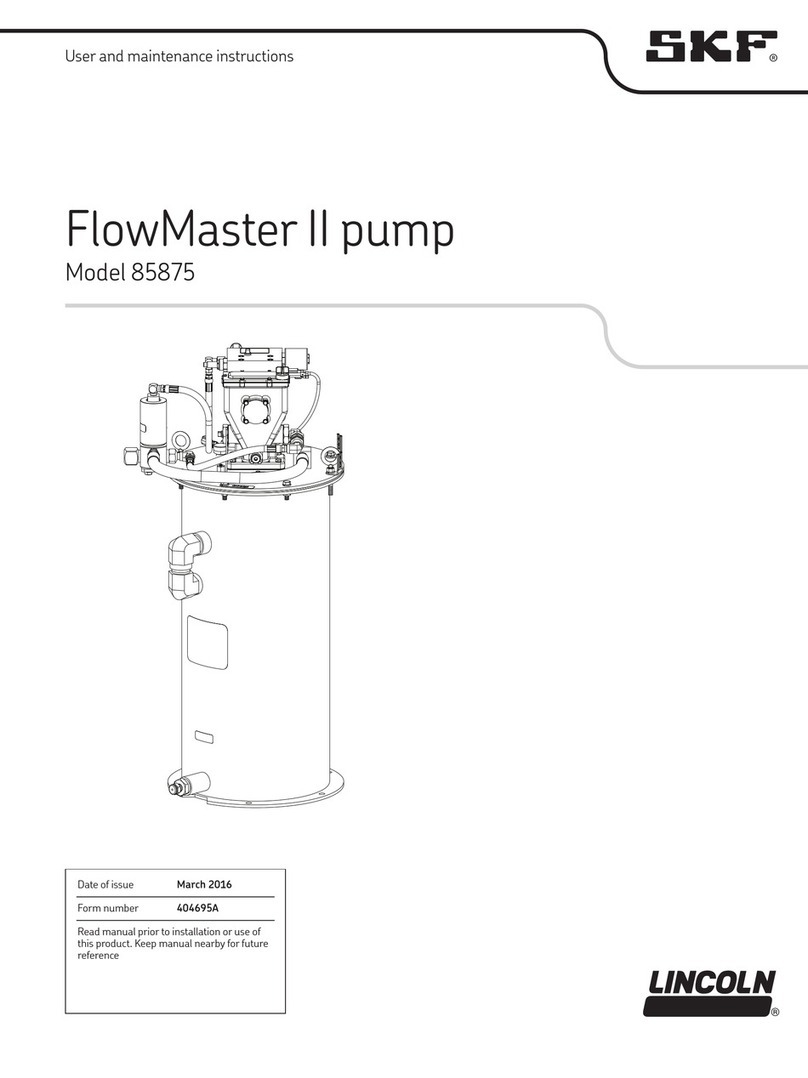

Multiline Pump Model 230

Subject to change without notice

Page 4 from 22

Safet Instructions for the User/Operator

If warm or cold machine parts present hazards, the custo-

mer must protect them against accidental contact.

Do not remove protection devices for moving parts while

the machine is in operation.

Dispose of leakages of harmful materials so as to jeopardi-

ze neither persons nor the environment. The requirements

of the law must be satisfied.

Exclude danger caused by electrical current for details

refer to the applicable specifications of VDE and the local

power supply companies).

Safet Instructions of maintenance, inspection

and installation work

The user must make sure that all maintenance, inspection

and installation work is executed by authorized and quali-

fied experts who have thoroughly read the Operating

Instructions.

On no account may work be done on the machine while the

machine is in operation. Follow all instructions for shutting

down the machine as described in the Operating Instruc-

tions.

Reassemble all safety and protection devices immediately

after completion of the cleaning procedure.

Decontaminate pumps and pump units delivering harmful

materials.

Dispose of material harmful to the environment in accor-

dance with the applicable official regulations.

Before putting the pump/pump unit into operation, ensure

that all points given in the chapter

Putting into Operation are fulfilled.

Unauthorized Modification and Spare Parts

Production

Alteration and modifications of the machine are only

allowed if approved by the manufacturer. Original spare

parts and accessories authorized by the manufacturer

ensure safe operation.

If other parts are used, the manufacturer may be released

from its liability for the resulting consequences.

Inadmissible Operating Modes

The operational safety of the supplied product is only

granted if the product is operated according to the instruc-

tions given in the chapter Appropriate use. The maximum

ratings listed in the Technical Data must never be excee-

ded.

Commissioning of the product pump/pump unit) within the

European Union is forbidden until it has been decided that

the machine on which the product will be installed meets

the requirements of the EU guidelines.

Appropriate Use

The pump model 230 is exclusively designed for use in

centralized lubrication systems for dispensing lubricants.

On request, softeners for PVC and rubber can also be

dispensed if they are mentioned on a special registration

list.

The maximum ratings mentioned in the Technical Data,

particularly the maximum operating pressure of 350 bar,

must not be exceeded.

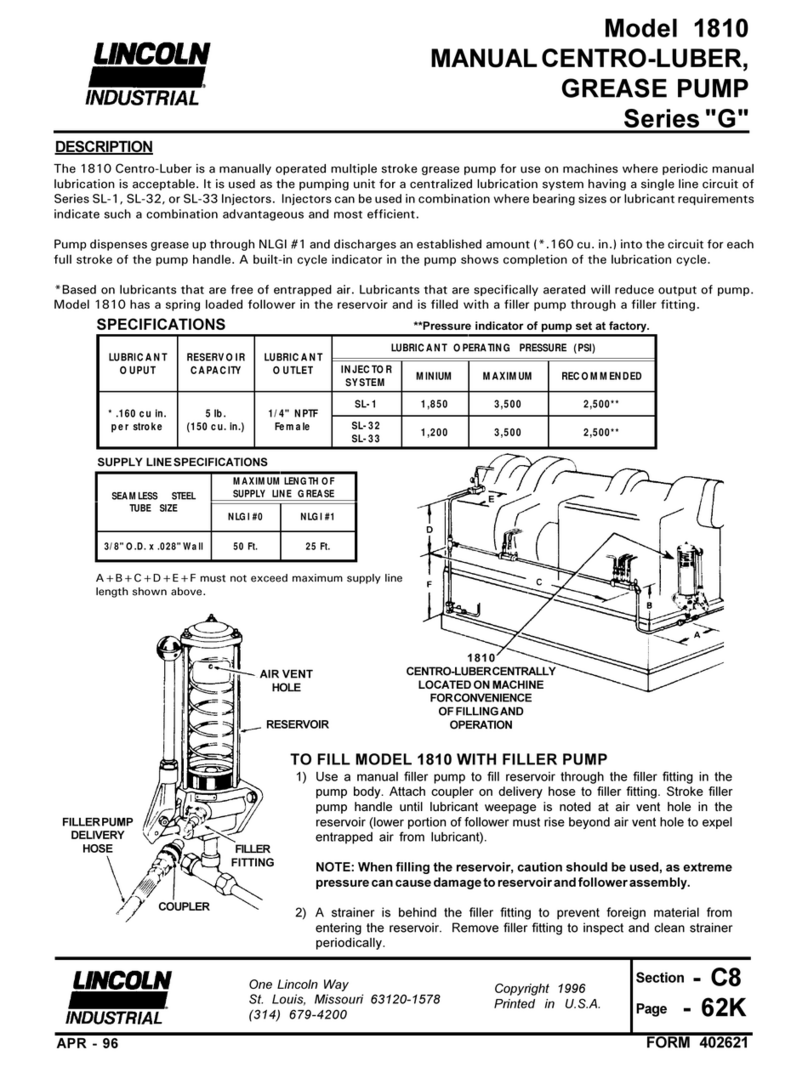

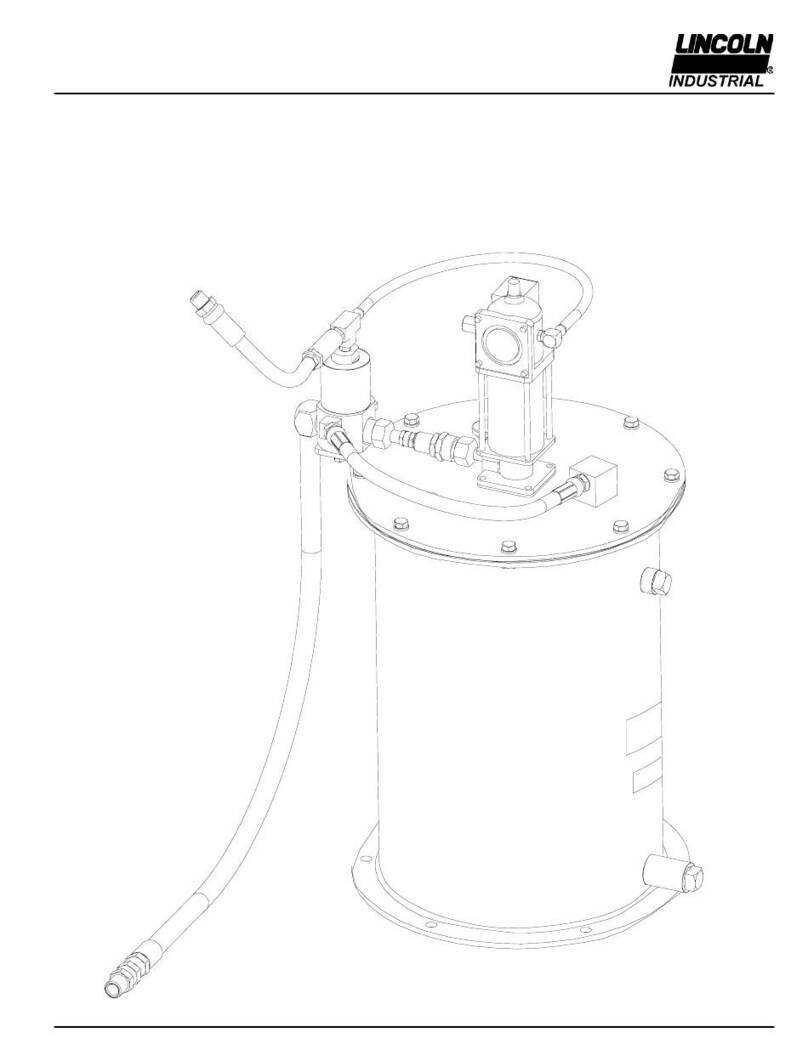

The multiline pump model 230 is a central lubrication pump

with 1 to 30 pump elements and thus 1 to 30 outlets. The

high pump operating pressure of 350 bar allows the pump

to be used as a multiline pump for the direct supply of

lubrication points, but also as a central lubrication pump in

large-sized progressive systems.

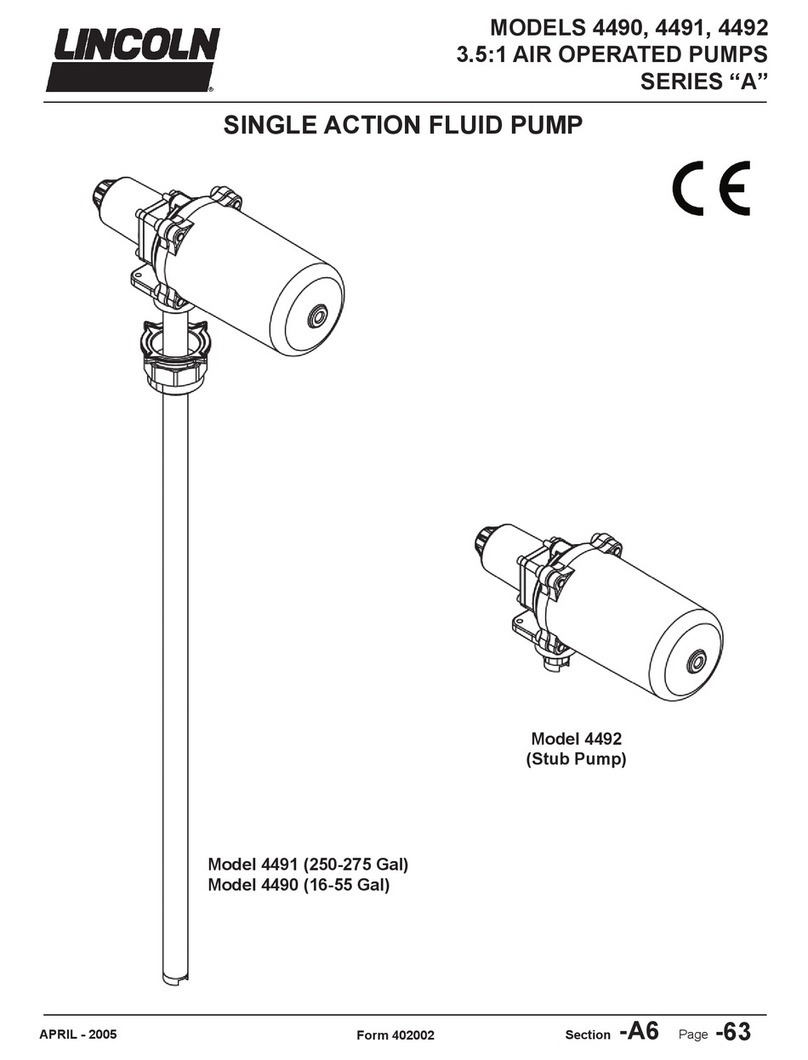

The great diversity of pump models allows the 230 multiline

pump to be used for a wide range of applications, e.g.

- machines in the steel industry eccentric presses, forging

machines)

- machines in the conveying technology cranes, drives for

conveyors, conveyor worms)

- machines in the construction industry stone crushers),

rubber and plastic mixers and rolling mills.

Any other use is not in accordance with the instruc-

tions and will result in the loss of claims for guarantee

and liability.