C.

D.

will be more prevalent when pump

ing viscous liquids. When pumping

thick heavy materials the suction

line must be kept as large in diameter

and as short as possible, to keep

suction loss minimal.

Low flow rate and slow cycling rate

indicate restricted flow through the

discharge line. Low flow rate and

fast cycling rate indicate restriction

in suction line or air leakage into

suction.

Unstable cycling indicates improper

check valve seating on one chamber.

This condition is confirmed when

unstable cycling repeats consistently

on alternate exhausts. Cycling that

is not consistently unstable may

indicate partial exhaust restriction

due to freezing and thawing of ex-

haust air. Use of an anti-freeze lubri-

cant in an air line lubricator should

solve this problem.

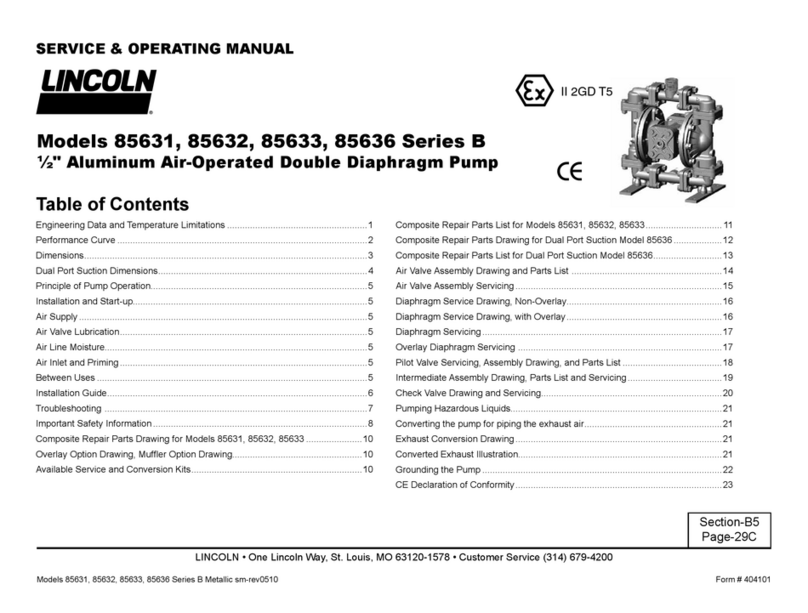

CHECK VALVE SERVICING

Whether removing cap-

screws on suction or discharge

valve retainer/cap, make sure

all pressure on suction and

discharge side of pump has

been relieved. Re-lock wire the

capscrews before continuing

use.

Need for inspection or service is

usually indicated by poor priming, un-

stable cycling, reduced performance or

the pump’s cycling but not pumping.

Inspect the surfaces of both check

valve and seat for wear or damage that

could prevent proper sealing. If pump is

to prime properly, valves must seat air

tight.

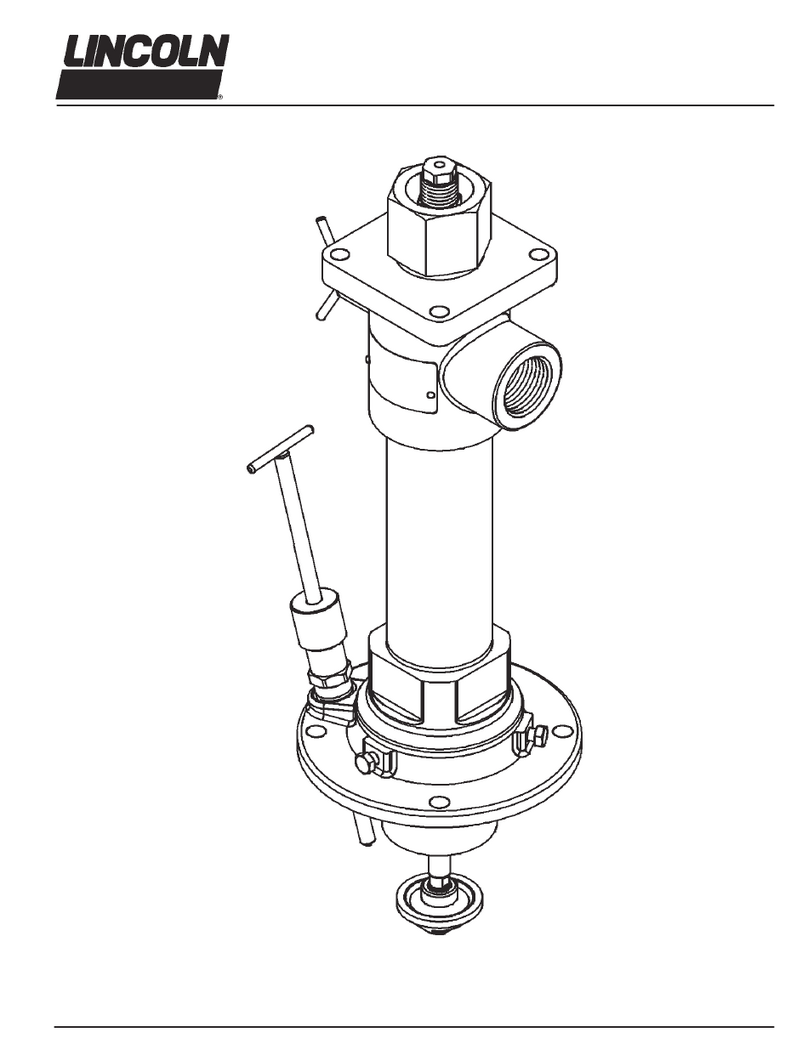

DIAPHRAGM SERVICING

Remove the eight nuts securing the

outer diaphragm chamber flange and

remove the chamber. Loosen the cap-

screw securing the diaphragm and plate

to the rod by leaving the diaphragm

engaged with the capscrews around

the outer flange, preventing rotation of

the rod. DO NOT USE AWRENCH ON

THE DIAPHRAGM ROD. FLAWS ON

THE SURFACE MAY DAMAGE BEAR-

INGS AND SEAL.

During reassembly make certain that

the rubber bumper is on the rod on each

side. install the diaphragm with the

natural bulge outward as indicated on

the diaphragm. Install the heavier plate

on the outside of the diaphragm and

make certain that the large radius side

of both plates aretoward the diaphragm.

Place the sealing washer between the

inner diaphragm plate and the end of

the rod. Tighten thecapscrew toapprox-

imately 25 ft. Ibs (3.456 kilograms/

meters). Torque while allowing the dia-

phragm to turn freely with plates. Use a

wrench on the capscrew of the opposite

side to keep rod from rotating. If the

opposite chamber is assembled, the rod

need not be held.

When reassembling the outer

chambers and the manifold, the bolts

securing the manifold flange to the

chamber should be snugged prior to

tightening the chamber bolts, to insure

that the chamber port flange is square

with the manifold flange. Finish tight-

ening the manifold flange bolts after

chamber bolting is secured.

AIR DISTRIBUTION

VALVE SERVICING

The spool and sleeve are rust and

corrosion resistant brass and hardened

stainless steel. The spool is closely

sized to the sleeve and should slide

freely. Accumulation of dirt and oils may

prevent thepump from cycling. Remove

the valve body from the center pump

housing, remove the end caps, and push

the spool out of the sleeve. Wash the

parts in cleaning solvent or kerosene,

and check the spool and sleeve for

possible roughness, nicks or scratches.

Use afine stone or crocus cloth to care-

fully remove any irregular marks on the

surfaces. When the spool slides freely

on the sleeve, coat the parts with light

oil and reassemble. The four capscrews

inserted through the valve body cap to

hold the air valve to the intermediate

section should be torqued to 150 in./lbs.

(1.728 kilograms/meter).

PILOT VALVE SERVICING

This assembly is reached by remov-

ing the air distribution valve body from

the pump and lifting the pilot valve out

of the intermediate housing.

Most problems with the pilot valve

can be corrected by replacing the o-

rings. Always grease the spool prior to

Inserting it into the sleeve. If the sleeve

IS removed from the body, reinsertion

must be at the chamfered side. Grease

the o-rings to slide the sleeve into the

valve body Securely insert the retain-

ing ring around the sleeve. When rein-

serting the pilot valve, push both plung-

ers (located inside the intermediate

bracket) out of the path of the pilot

valve spool ends to avoid damage,

PILOT VALVE ACTUATOR

SERVICING

Bushings for the pilot valve actua-

tors are held in the inner chambers with

retaining rings. An o-ring IS behind

each bushing. If the plunger has any

sideways motion check o-rings and

bushings for deterioration /wear. The

plunger may be removed for inspection

or replacement. First remove the air

distribution valve body and the pilot

valve body from the pump. The plung-

ers can be located by looking into the

intermediate. It may be necessary to

use afine piece of wire to pull them out,

The bushing can be turned out through

the inner chamber by removing the outer

chamber assembly. Replace the bush-

ings if pins have bent.

ANote about Air Valve

Lubrication

The Lincoln pump’s pilot valve and

main airvalve assemblies aredesigned

to operate WITHOUT lubrication. This

is the preferred mode of operation.

There may be instances of personal

preference, orpoor quality air supplies

when lubrication of the compressed air

supply is required. The pump air sys-

tem will operate with properly lubri-

cated compressed air supplies. Proper

lubrication of the compressed air sup-

ply would entail the use of an air line

lubricator (available from Lincoln) set

to deliver one drop of 10 wt, non-

detergent oil for every 20 SCFM of air

the pump consumed at its point of op-

eration. Consult the pump’s published

Performance Curve to determine this

It is important to remember to in-

spect the sleeve and spool set rou-

tinely. It should move back and forth

freely. This IS most important when the

air supply is lubricated. If aIubricator

is used, oil accumulation will, overtime,

collect any debris from the compressed

air. This can prevent the pump from

operating properly.

RETAIN THIS INFORMATION FOR FUTURE REFERENCE

When ordering replacement parts, list: Part Number, Description, Model Number, and Series Letter.

LINCOLN provides aDistributor Network that stocks equipment and replacement parts.